Low-carbon high-tenacity super-thick steel plate and manufacturing method thereof

A technology of extra-thick steel plate and high toughness, which is applied in the field of low-carbon high-toughness extra-thick container steel plate and its manufacturing. It can solve the problems of affecting the use and poor low-temperature toughness of the steel plate, and achieves short production cycle, excellent core performance and compactness. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

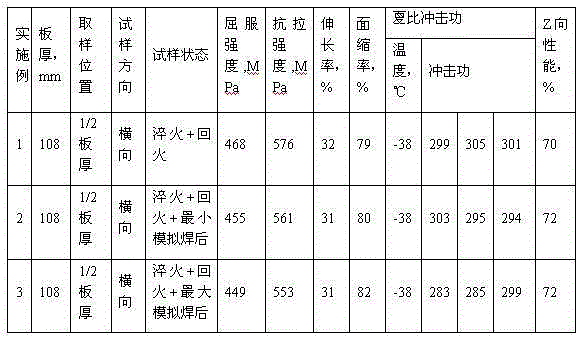

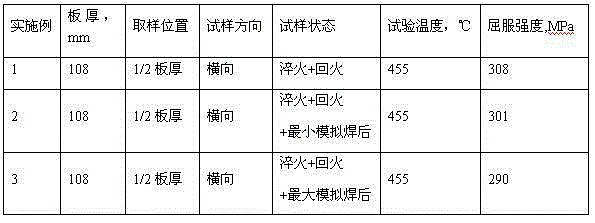

Embodiment 1

[0021] The thickness of the low-carbon high-toughness extra-thick steel plate of this embodiment is 108 mm, and its chemical composition is calculated by mass percentage: C: 0.08%, Si: 0.20%, Mn: 0.45%, P: 0.004%, S: 0.002%, Ni: 0.38%, Cr: 1.10%, Cu: 0.03%, Mo: 0.55%, Sb: 0.001%, Sn: 0.001%, As: 0.001%, H: 0.00008%, O: 0.0014%, N: 0.0032%, The balance is Fe and unavoidable impurity elements.

[0022] The manufacturing process of the steel plate is to configure the smelting raw materials according to the chemical composition of the above-mentioned steel plate products. (1) Smelting and continuous casting: the smelting raw materials are pretreated by KR molten iron in sequence, and the converter smelting: the converter tapping P≤0.008%, and the converter tapping temperature is 1610~1650℃, slag removal treatment; LF refining: white slag retention time not less than 25min, total refining time not less than 45min, slag removal when molten steel S≤0.003%; RH vacuum degassing refinin...

Embodiment 2

[0025]The thickness of the low-carbon high-toughness container steel plate of this embodiment is 108 mm, and its chemical composition is calculated by mass percentage: C: 0.10%, Si: 0.30%, Mn: 0.50%, P: 0.002%, S: 0.001%, Ni : 0.25%, Cr: 0.9%, Cu: 0.03%, Mo: 0.60%, Sb: 0.001%, Sn: 0.001%, As: 0.001%, H: 0.00008%, O: 0.0014%, N: 0.003%, Yu The amount is Fe and unavoidable impurity elements.

[0026] The production method of steel plate is basically the same as the production method of embodiment 1, but there are differences in the state of the test sample blank, and the specific differences are as follows:

[0027] In order to simulate the post-welding stress-relieving heat treatment process of the steel plate, after the sample blank is removed from the steel plate, it is first kept in a small furnace at 675°C for 4 hours, which is the minimum simulated post-weld heat treatment, and then the mechanical properties are tested.

[0028] Experiments prove that the steel plate of t...

Embodiment 3

[0030] The thickness of the low-carbon high-toughness container steel plate of this embodiment is 108 mm, and its chemical composition is calculated by mass percentage: C: 0.11%, Si: 0.20%, Mn: 0.6%, P: 0.004%, S: 0.002%, Ni : 0.32%, Cr: 1.15%, Cu: 0.03%, Mo: 0.45%, Sb: 0.001%, Sn: 0.001%, As: 0.001%, H: 0.0001%, O: 0.0012%, N: 0.0032%, Yu The amount is Fe and unavoidable impurity elements.

[0031] The steel plate is that the production method is basically the same as the production method of embodiment 1, but there are differences in the state of the inspection sample blank, and the specific differences are as follows:

[0032] In order to simulate the post-welding stress-relieving heat treatment process of the steel plate, after the sample blank is taken from the steel plate, it is first kept in a small furnace at 675°C for 12 hours, which is the maximum simulated post-weld heat treatment, and then the mechanical properties are tested.

[0033] Experiments prove that the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com