Cr-Mo low-alloy steel plate for pressure vessel and preparation method of Cr-Mo low-alloy steel plate

A pressure vessel and low alloy technology, applied in the field of Cr-Mo low alloy high performance pressure vessel steel plate, can solve the problems of high heat treatment cost, complex production process and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]In order to highlight the objectives, technical solutions, and advantages of the present invention, the present invention will be further described below in connection with the embodiments of the present invention, and examples are illustrative of the invention. The technical solution of the present invention is not limited to the specific embodiments listed below, and any combination of each of the specific embodiments is further included.

[0046]Any of the features disclosed in this specification unless otherwise specified, it can be replaced by other equivalent or similar purposes. Each feature is just an example of a series of equivalent or similar features unless specifically described.

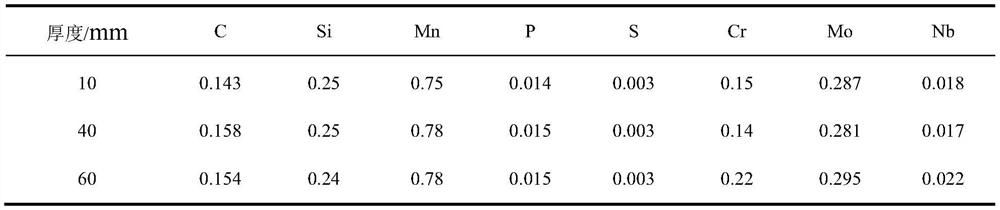

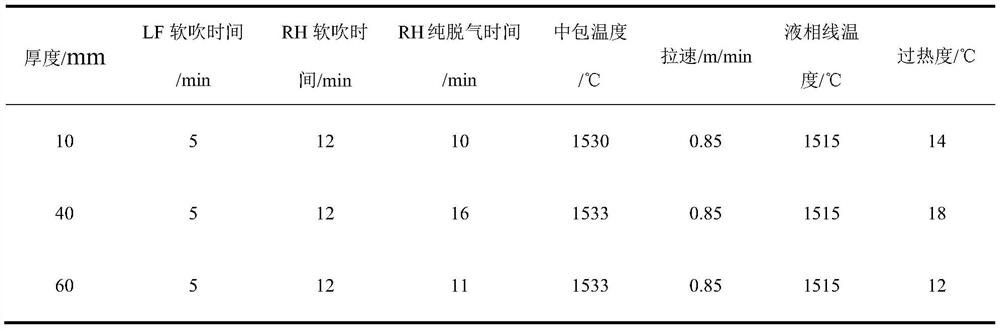

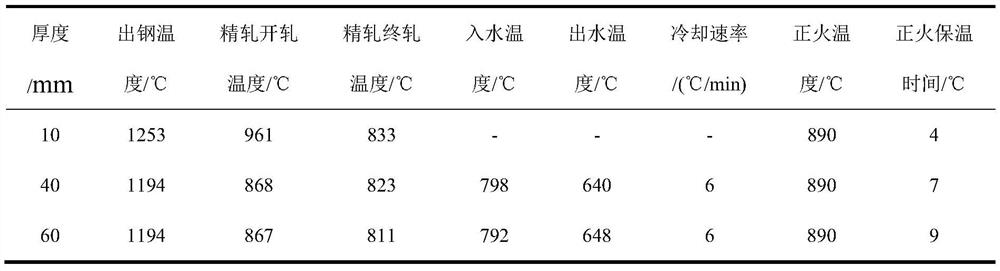

[0047]1) Smelting continuous casting: It is used to use Kr pretreatment in the converter, iron and self-produced scraps in the converter, and obtain the primary steel water, after the primary steel water, LF + RH double refining, casting, The slab is obtained, and the slabs are then cooled an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com