Oil layer respirator

A respirator and oil layer technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of single action, damage to oil layers, and high implementation costs, achieve unique mechanism of action, improve oil well production, and technical ideas innovative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

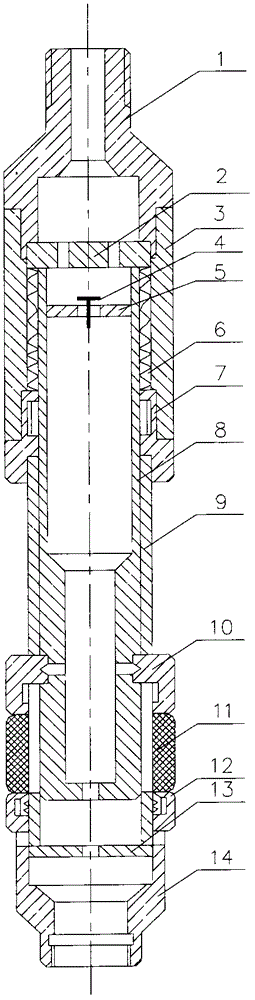

[0010] The lower end of the outer wall of the upper joint 1 is sequentially connected with the outer pipe 3 of the damping chamber, the damping spring seat 7, the outer pipe 9 of the sealing chamber, the damping slider 12, the lower liquid passage plate 13, and the lower joint 14, and the upper liquid passage plate 2 at the lower end of the inner side of the upper joint 1 Connect the sealing plunger 8, the valve body seat 5, and the limit sliding body 10 to form a reciprocating combined part. The valve body 4 is installed on the valve body seat 5, and the damping chamber outer tube 3 and the sealing plunger 8 are installed Between the damping spring 6 , the limiting sliding body 10 and the damping sliding body 12 , an expansion-contracting rubber tube 11 is installed. The sealing plunger 8 is slidably matched with the outer tube 9 of the sealing chamber. When the pressure on the upper part of the valve body 4 increases, the valve body 4 closes to form a downward-moving power ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com