Silencing swirling flow tee of single-spiral joint pipe

A three-way, single-spiral technology, applied in the direction of pipes/pipe joints/fittings, pipes, pipe components, etc., can solve the problems of poor noise reduction, affecting people's lives, and unable to change the form of water flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

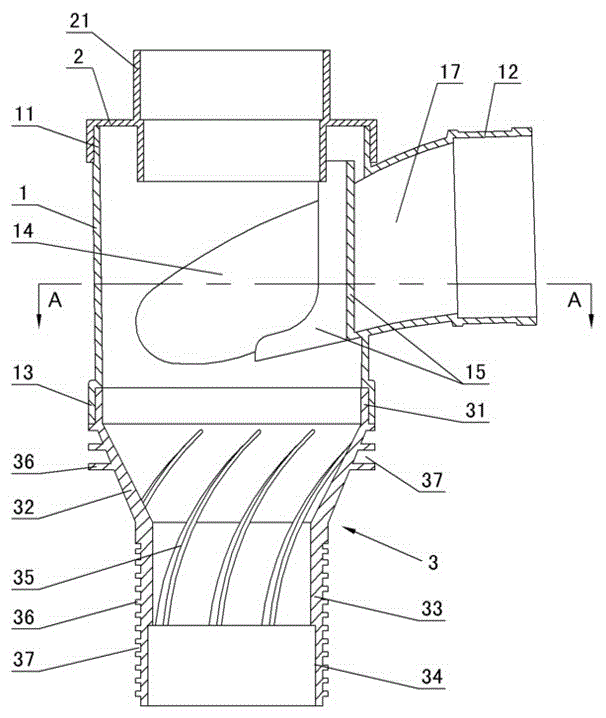

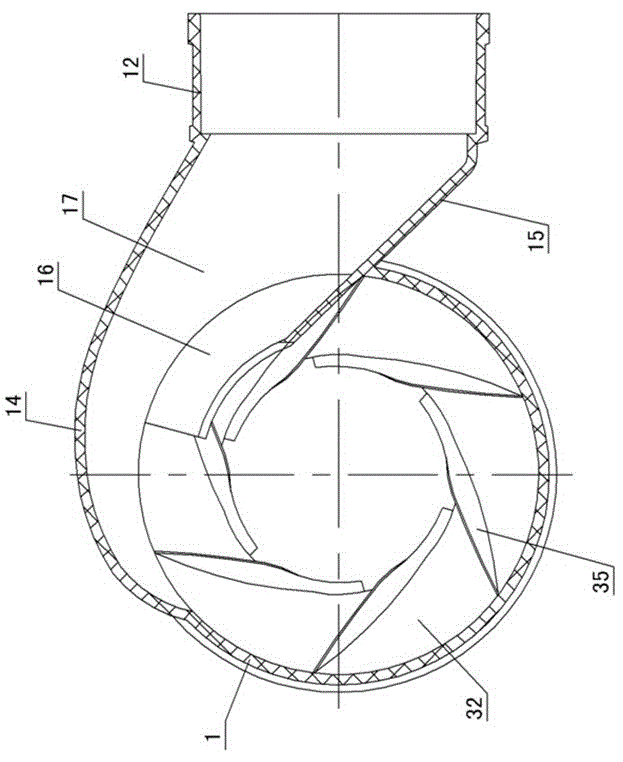

[0009] The invention relates to a sound-absorbing swirl three-way pipe with a single spiral joint, such as figure 1 — figure 2 As shown, it is characterized in that: a main body 1 including a three-way pipe, on which an upper interface 11, a side spiral tube 12 and a lower interface 13 are formed, the upper interface is connected to the upper connection cover 2, and the upper connection cover is formed with a socket The outer tube 21, the side helical tube 12 is located on the outer wall of the main body 1 and is formed with an arc-shaped protrusion 14, and the side helical tube is located on the inner wall of the main body and is formed with an inner oblique baffle 15 and a lower baffle 16, and the arc protrudes and the inner oblique baffle A spiral hole 17 is formed between the lower baffle plate, the lower interface 13 is connected to the swirl tube 3, and the swirl tube includes an upper socket inner tube 31, the socket inner tube is plugged with the inner wall of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com