Differential ultrasonic low frequency vibration measuring device and method

A technology of low-frequency vibration and measurement method, which is applied in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, and electrical devices, etc., which can solve the problems of high temperature measurement accuracy and complex measurement circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

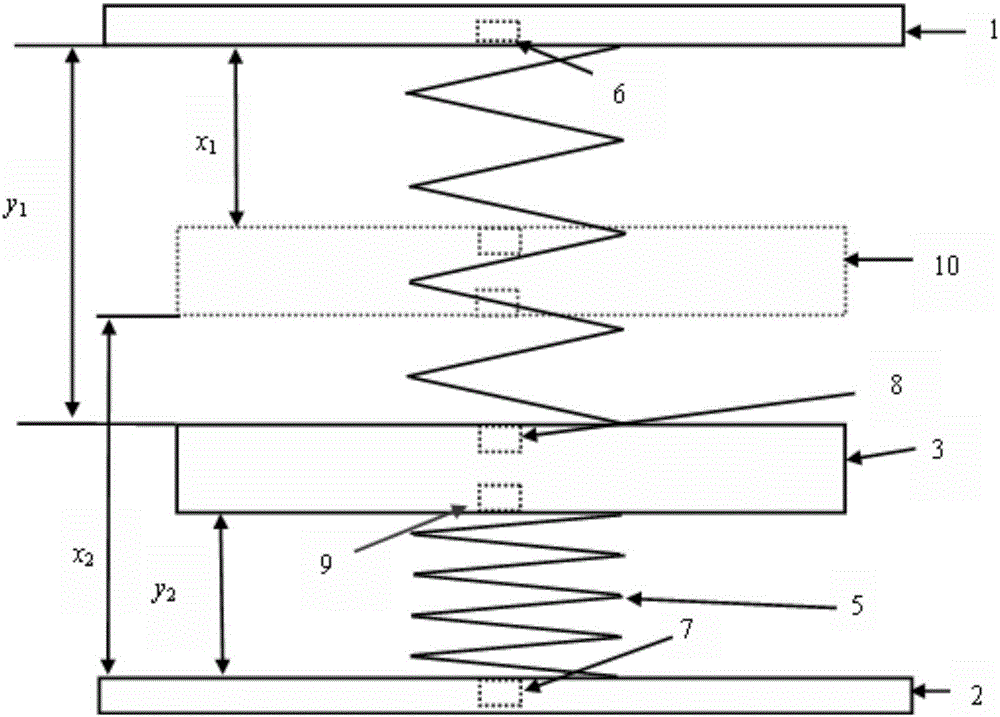

[0029] see figure 1 As shown, a differential ultrasonic low-frequency vibration measuring device includes a horizontal fixed plate 2 and a horizontally arranged fixed plate 1 above the fixed plate 2, and a horizontal arrangement between the fixed plate 1 and the fixed plate 2. There is a mass block 3, a support spring 1 4 is connected between the center of the bottom surface of the fixed plate 1 and the center of the top surface of the mass block 3, and a support spring 2 5 is connected between the center of the top surface of the fixed plate 2 and the center of the bottom surface of the mass block 3. An ultrasonic transmitting sensor 16 is embedded in the center of the bottom surface of the plate 1, an ultrasonic transmitting sensor 27 is embedded in the center of the top surface of the fixed plate 22, and an ultrasonic receiving sensor 18 is embedded in the center of the top surface of the quality block 3 corresponding to the position of the ultrasonic transmitting sensor 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com