Gum dipping fiber mechanical property testing method

A test method and dipping technology, applied in the field of testing the mechanical properties of materials, can solve the problems of complicated steps, expensive testing equipment, poor measurement accuracy, etc., and achieve the effects of accurate and reliable data, low cost, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following describes in detail the testing method of the mechanical properties of the impregnated fiber of the present invention with reference to the drawings and embodiments of the specification:

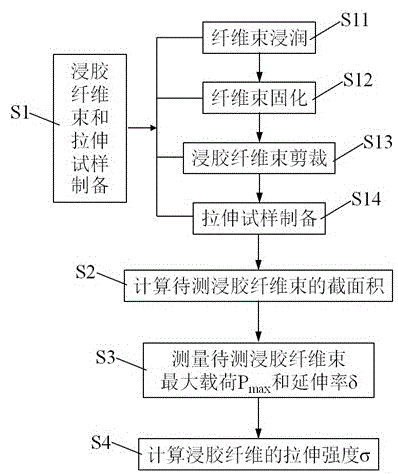

[0037] Such as figure 1 As shown, a testing method for the mechanical properties of dipped fibers includes the following steps:

[0038] (Ⅰ) Preparation of dipped fiber bundles and tensile specimens

[0039] (Ⅰ) Fiber bundle infiltration

[0040] The fiber bundle 3 is immersed in the matched resin and fully immersed to be uniform and without colloidal particles, and the fiber content is controlled at 80% to 90%;

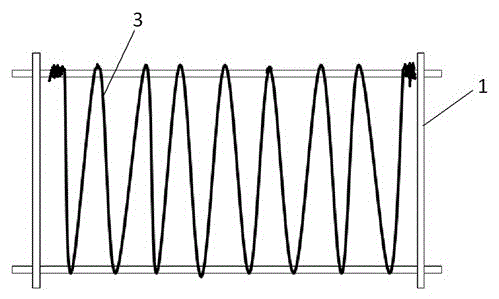

[0041] (Ⅱ) Fiber bundle curing

[0042] Fix the fully infiltrated fiber bundle 3 on the support 1 and place it at 60℃~150℃ to heat for 6h~12h to solidify to form the impregnated fiber bundle;

[0043] (Ⅲ) Cut the dipped fiber bundle

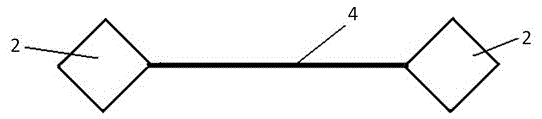

[0044] Take off the dipped fiber bundle obtained after curing, cut off both ends and leave the length at 150mm~200mm to obtain the test dipp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com