Detection method of shock resistance of diamond compact

A technology of diamond composite sheet and impact resistance, which is applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve problems such as easy deformation, poor data reliability, and increased contact area, achieve uniform density, solve instability and The effect of large error and high bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Ingredients: Weigh raw materials according to the following weight percentages: Co: 6%, WC: 89%, W: 3.5%, VC: 1%, CeO2: 0.5%;

[0029] (2) Sintering: Put the material obtained in step (1) into a mold for spark plasma sintering at a temperature of 1100° C., a pressure of 30 MPa, and a holding time of 30 minutes.

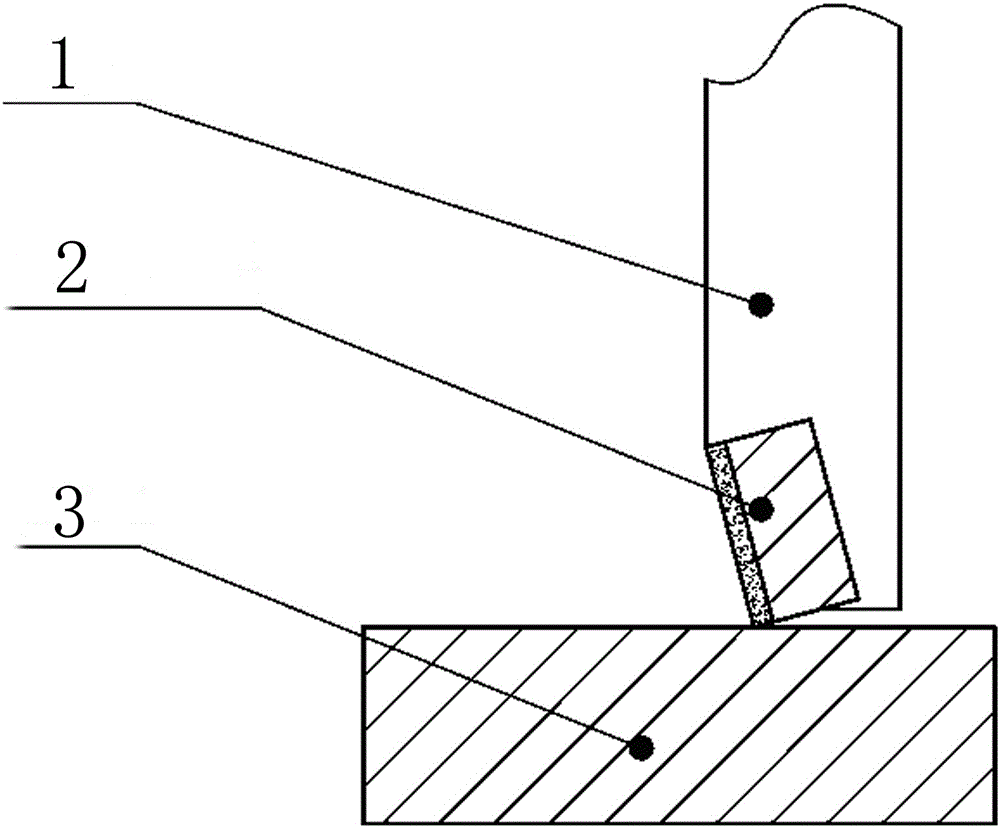

[0030] (3) Installation: install the cemented carbide prepared in step (2) on the workbench, and install the chamfered diamond composite sheet on the cantilever beam at the same time, and set the single impact energy value to 0.7J.

[0031] (4) Work: Turn on the power switch, the cantilever beam starts to move up and down, the lifting and falling height of the knife handle is 4cm, use the principle of gravity acceleration to detect the impact resistance of the diamond composite sheet, until visible cracks appear on the surface of the diamond composite sheet or break. Stop operate.

[0032] (5) Calculation: According to the product value of the number of i...

Embodiment 2

[0039] (1) Ingredients: Weigh raw materials according to the following weight percentages: Co: 15%, WC: 80%, W: 4%, VC: 0.5%, CeO2: 0.5%;

[0040] (2) Sintering: Put the material obtained in step (1) into a mold for spark plasma sintering at a temperature of 1300° C., a pressure of 10 MPa, and a holding time of 10 minutes.

[0041] (3) Installation: install the cemented carbide prepared in step (2) on the worktable, and install the chamfered diamond composite sheet on the cantilever beam at the same time, and set the single impact energy value to 1 J.

[0042] (4) Work: Turn on the power switch, the cantilever beam starts to move up and down, the lifting and falling height of the knife handle is 6cm, use the principle of gravity acceleration to detect the impact resistance of the diamond composite sheet, until visible cracks or breakage appear on the surface of the diamond composite sheet and stop operate.

[0043] (5) Calculation: According to the product value of the numb...

Embodiment 3

[0050](1) Ingredients: Weigh raw materials according to the following weight percentages: Co: 10%, WC: 85%, W: 3.5%, VC: 1%, CeO2: 0.5%;

[0051] (2) Sintering: Put the material obtained in step (1) into a mold for spark plasma sintering at a temperature of 1200° C., a pressure of 20 MPa, and a holding time of 20 minutes.

[0052] (3) Installation: install the cemented carbide prepared in step (2) on the workbench, and install the chamfered diamond composite sheet on the cantilever beam at the same time, and set the single impact energy value to 1.6J.

[0053] (4) Work: Turn on the power switch, the cantilever beam starts to move up and down, the lifting and falling height of the knife handle is 9cm, use the principle of gravity acceleration to detect the impact resistance of the diamond composite sheet, until visible cracks or breakage appear on the surface of the diamond composite sheet. operate.

[0054] (5) Calculation: According to the product value of the number of imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap