Printing device

A kind of equipment and printing technology, applied in printing, typewriter, etc., can solve the problem of product flower shape limitation, achieve the effect of increasing diversity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

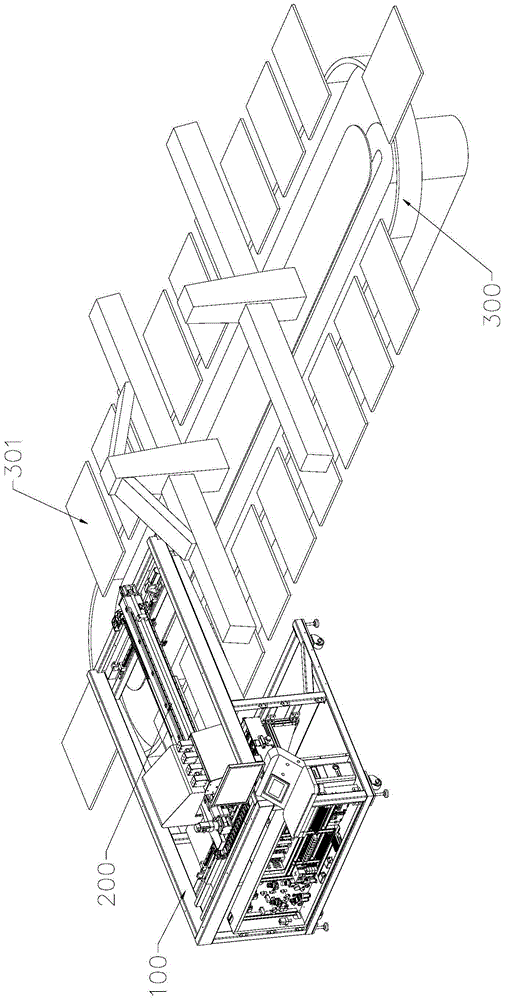

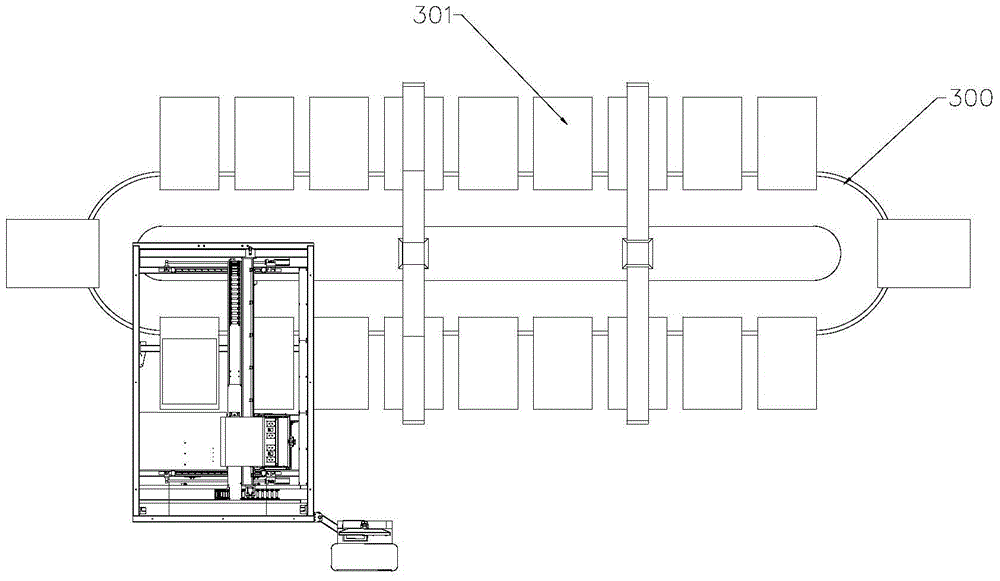

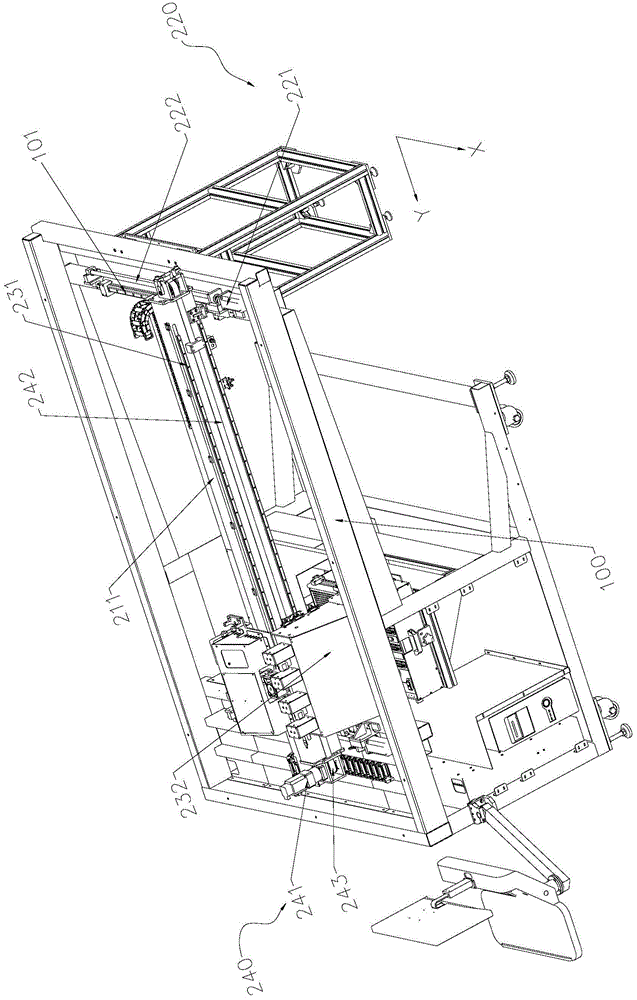

[0019] Such as Figure 1-3 Shown, be the printing equipment of the present invention, comprise screen printing station, ink-jet printing station, the bearing table 301 that is used to place printing medium, be used to drive bearing table 301 through screen printing station and ink-jet printing work The conveying device 300 of position; The inkjet printing station place is provided with inkjet printing device 200; The crossbeam 211 located above the conveying device 300, the first power mechanism 220 for driving the crossbeam 211 to move along the length direction of the first guide rail 101, the inkjet cart 232 used for inkjet printing and slidingly matched with the crossbeam 211, installed on the crossbeam 211 and is used to drive the second power mechanism 240 that the inkjet vehicle 232 moves along the length direction of the crossbeam 211; the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com