A wet tire with high operational stability

A technology for operational stability, wet tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of not reaching the normal service life of tires, high replacement costs, wear and tear, etc. To achieve the effect of improving operation stability, long service life and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

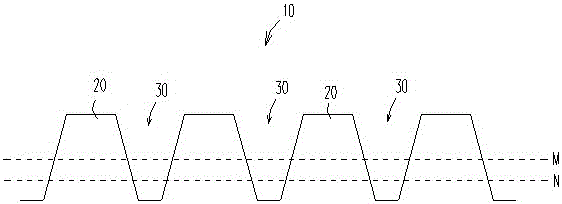

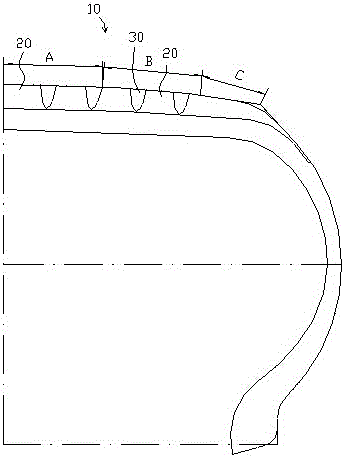

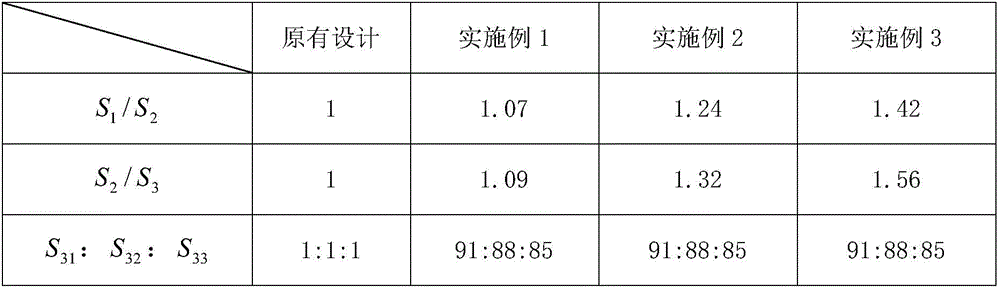

[0013] There are multiple circumferential main grooves and multiple pattern grooves on the tread of the wet tire, the circumferential main grooves extend in the tire circumferential direction, the pattern grooves extend in the tire width direction, the circumferential main grooves and the pattern grooves divide the tread into multiple pattern blocks. The top surface area of all pattern blocks constitutes the actual ground contact area of the tread, and the ratio of the top surface area to the tread determines the ground contact performance of the pattern blocks.

[0014] figure 1 A partial cross-sectional view of a pattern block is shown. On the tread 10 of a tire, the pattern block 20 is designed to be shaped like a trapezoid, and the circumferential main grooves 30 between the pattern blocks form a similar V-shaped structure, and the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com