Mechanical noise far field sound pressure prediction method based on inverse boundary element method

An inverse boundary element, mechanical noise technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, measurement devices, special data processing applications, etc. The effect of measuring convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

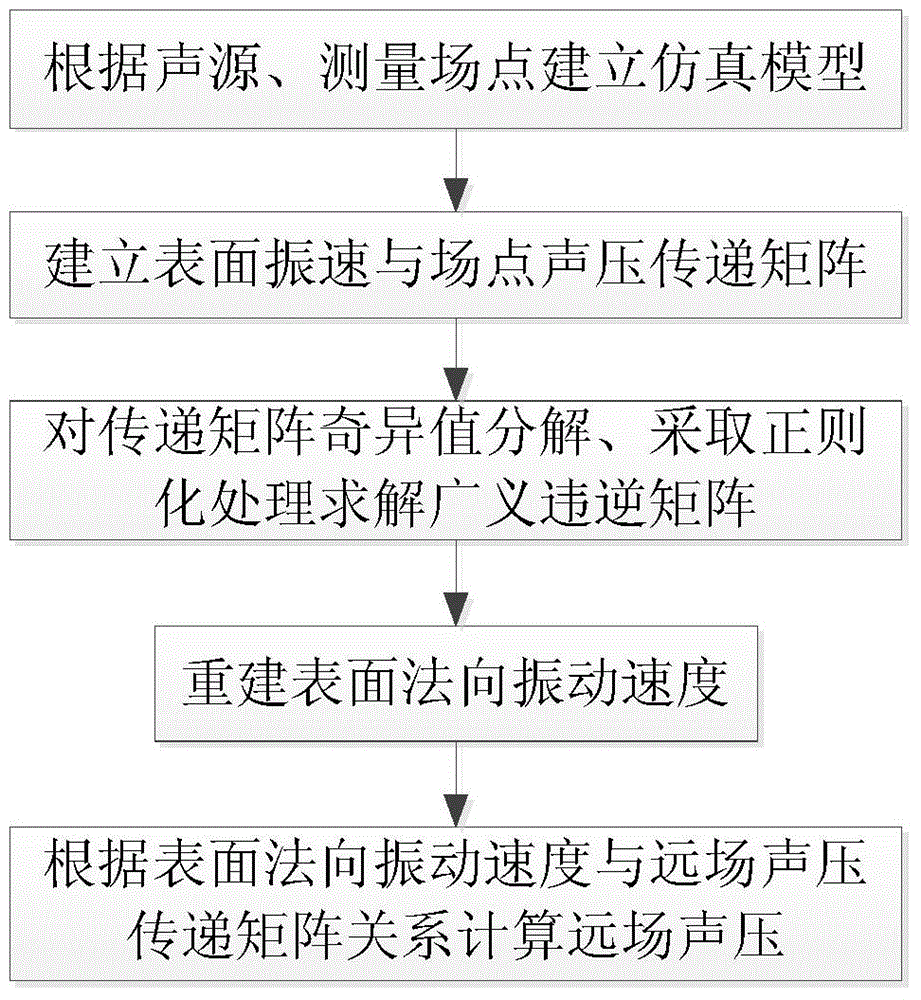

[0028] The present invention adopts the technical scheme for solving its technical problem, such as figure 1 Shown:

[0029] Step 1: Establish the simulation model of the sound source and test surface model. The grid unit of the vibration sound source model is required to be less than 1 / 6 of the wavelength corresponding to the maximum analysis frequency.

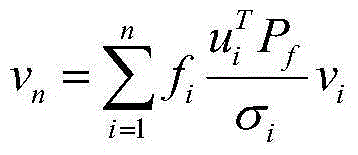

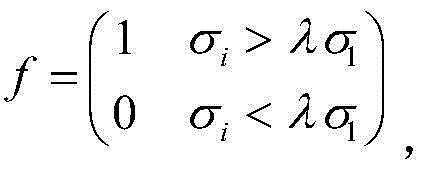

[0030] Step 2: Establish the transfer relationship matrix between the field point sound pressure and the mechanical surface vibration velocity. Establishment of Boundary Integral Equation Based on Boundary Element Method

[0031] p ( P ) = - ∫ s ( p ( Q ) ∂ Ψ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com