Layout method for shimmy damper

A layout method and shimmy reducer technology, applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., can solve problems such as large speed fluctuations, structural life of the transmission system, hidden dangers of helicopter flight safety, and collisions of transmission gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The layout method of the shock absorber involved in the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] The layout method of the shimmy reducer of the present invention comprises the following steps:

[0034] (1) A layout method for asymmetric inter-blade shimmy dampers is proposed through conventional layout analysis;

[0035] (2) Establish the dynamic model of the asymmetric interblade shimmy damper;

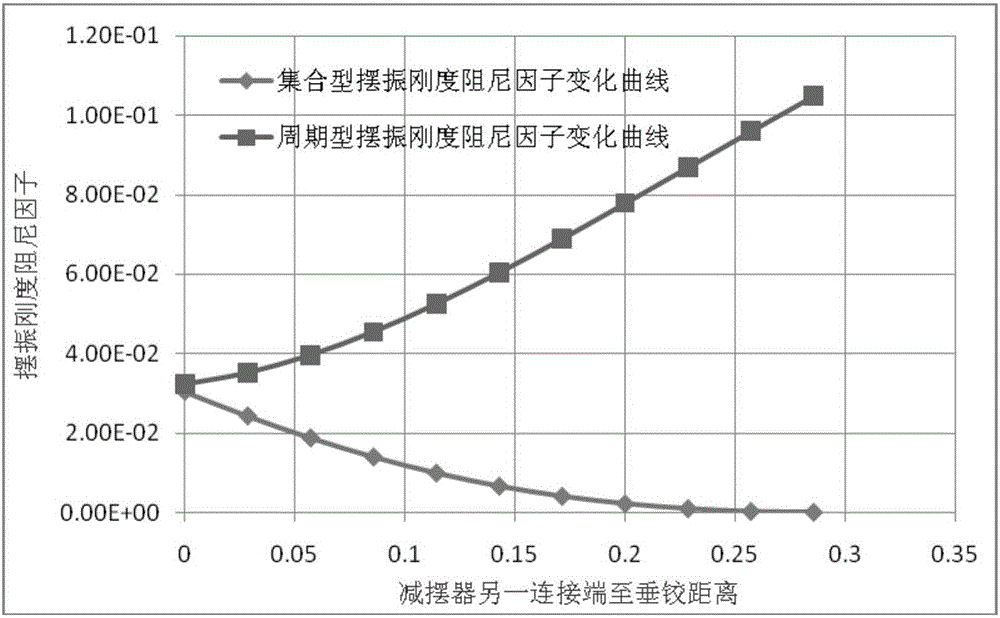

[0036] (3) Obtain the damping factor of the shimmy stiffness, and design the parameters of the asymmetric interblade shimmy damper.

[0037] In this embodiment, specifically,

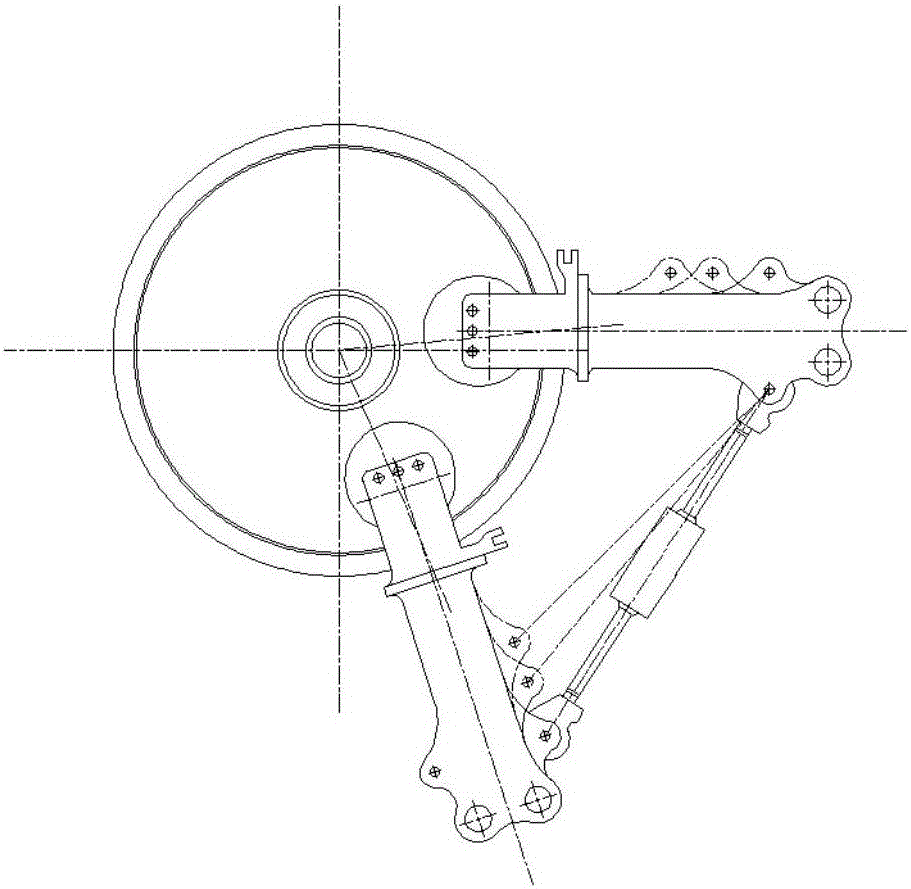

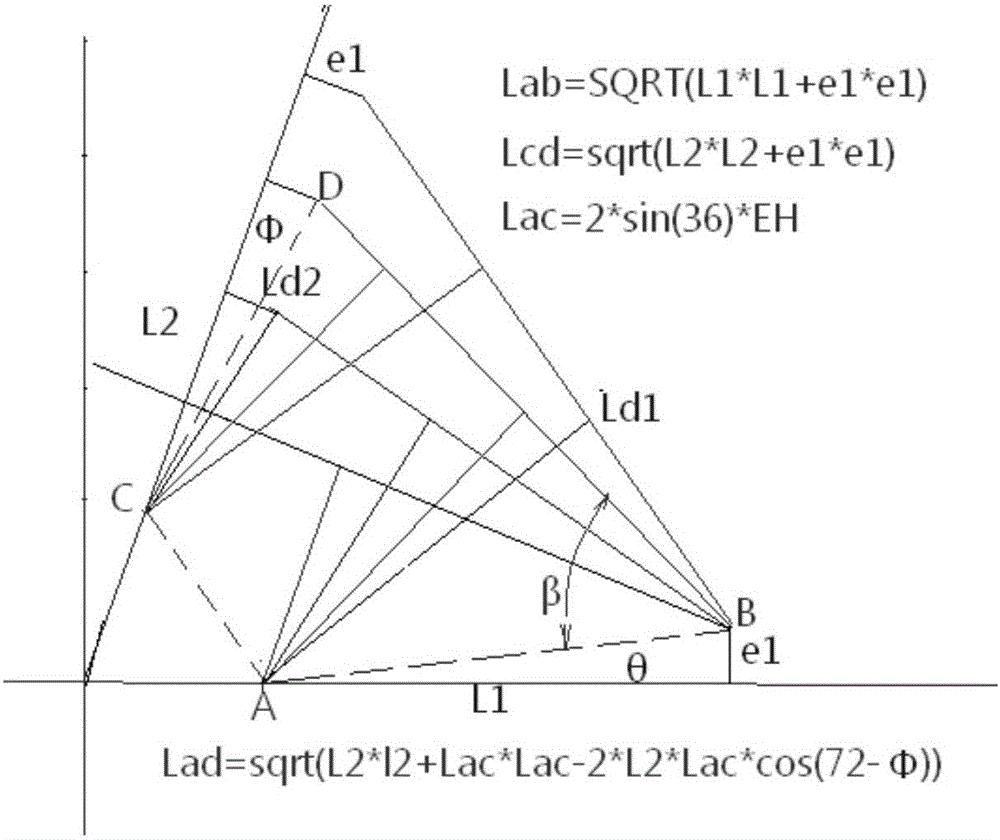

[0038] The first step: according to the characteristics of the installed rotor, establish a coordinate system describing the asymmetric interblade layout shimmy damper (between the Kth piece and the K+1th piece). Its structure can be simplified to this form, see figure 2 . Define the origin of the coordinate system as the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com