A High Power and Fast Response Laser Power Supply

A high-power power supply and fast-response technology, applied in the direction of excitation methods/devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

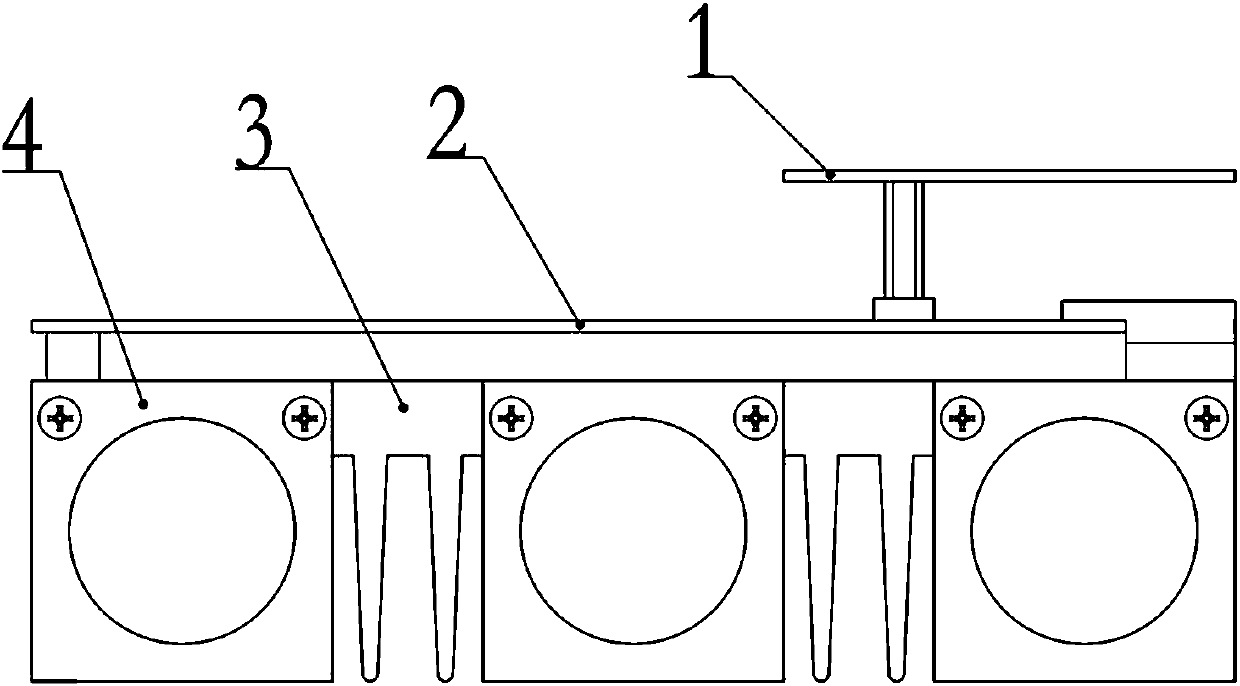

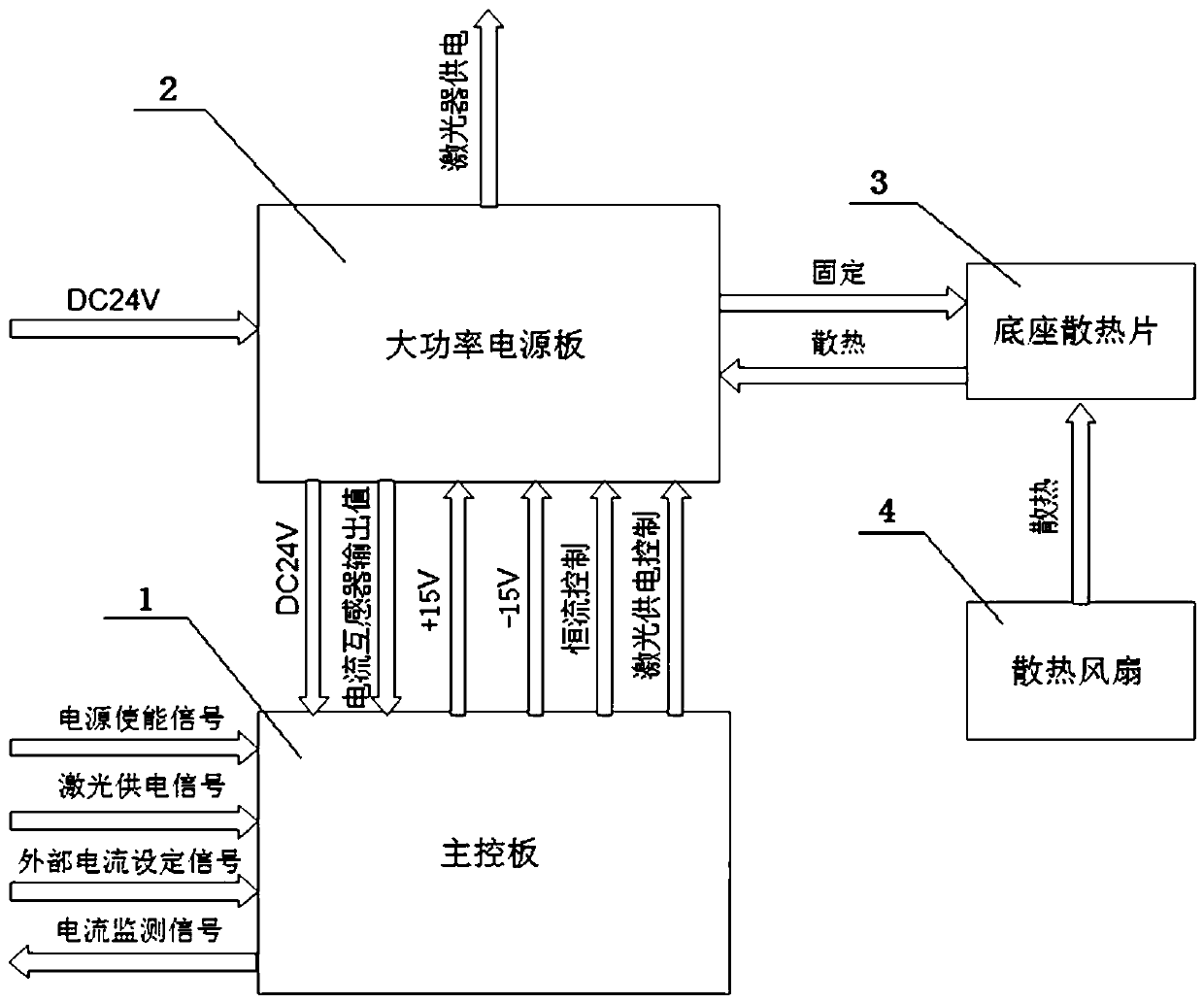

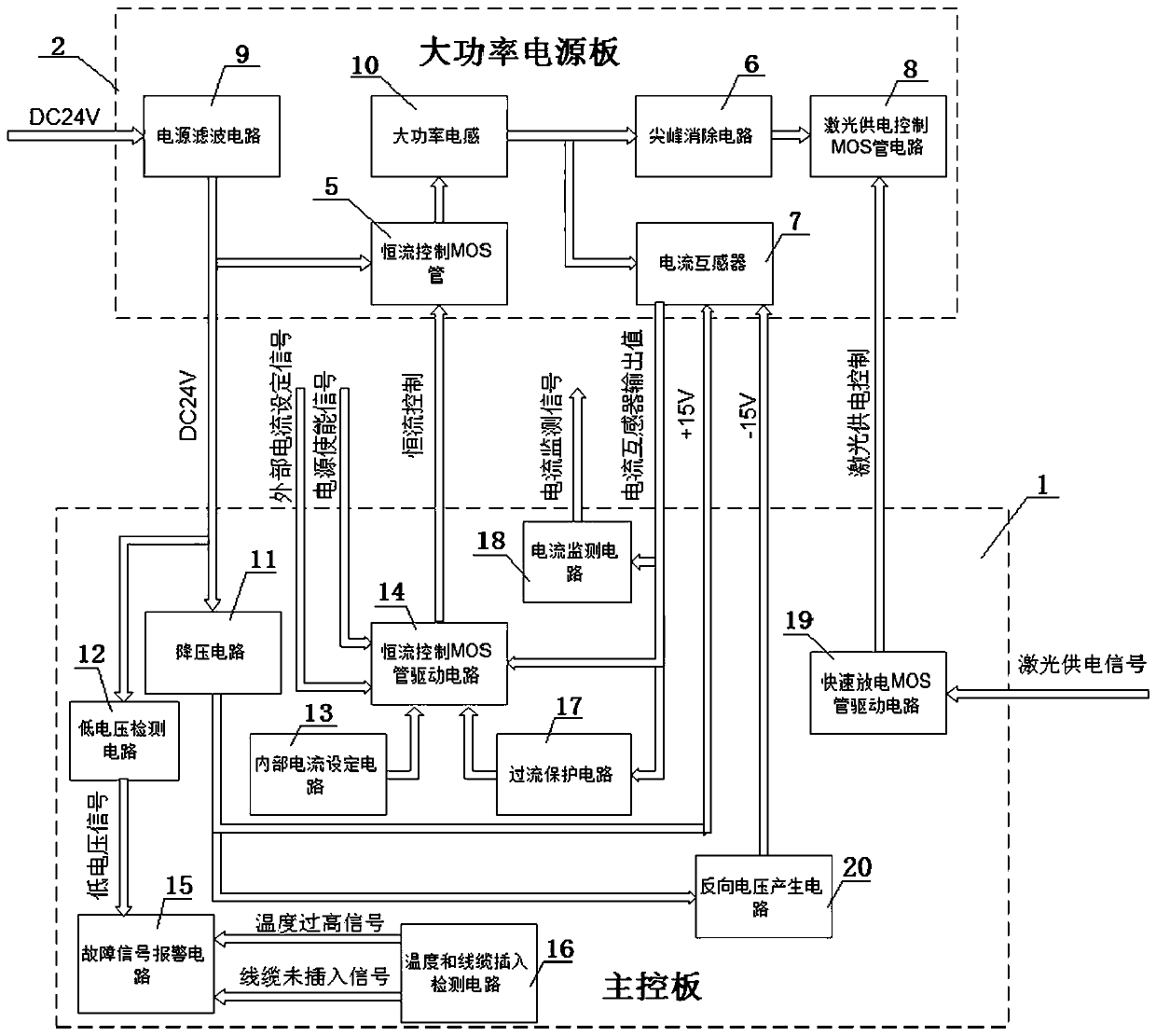

[0023] Such as figure 1 As shown, the structure schematic diagram of the high-power fast-response laser power supply of the present invention is given, which is composed of a main control board 1, a high-power power supply board 2, a base heat sink 3, and a cooling fan 4. The main control board 1 is fixed on a high-power On one side of the power board 2 , the heat sink 3 of the base is fixed on the other side of the power board 2 , and a plurality of cooling fans 4 are fixed on the heat sink 3 of the base. The heat dissipation fan 4 uses the grid groove on the heat sink 3 of the base as an air channel to increase the heat dissipation performance of the heat sink 3 of the base. Mounting holes are provided at the corresponding positions of the main control board 1 and the high-power power supply board 2. Use copper pillars or connectors of other material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com