A Potato Synchronous Pressure Bag Opening Height Adaptive Bagging Mechanism

An adaptive, bag-pressing technology, applied in applications, harvesters, excavator harvesters, etc., can solve the problems that forklifts are difficult to reach, unable to use the accompanying truck mode, unable to promote the ton bag + forklift mode, etc., to achieve fast replacement. bag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

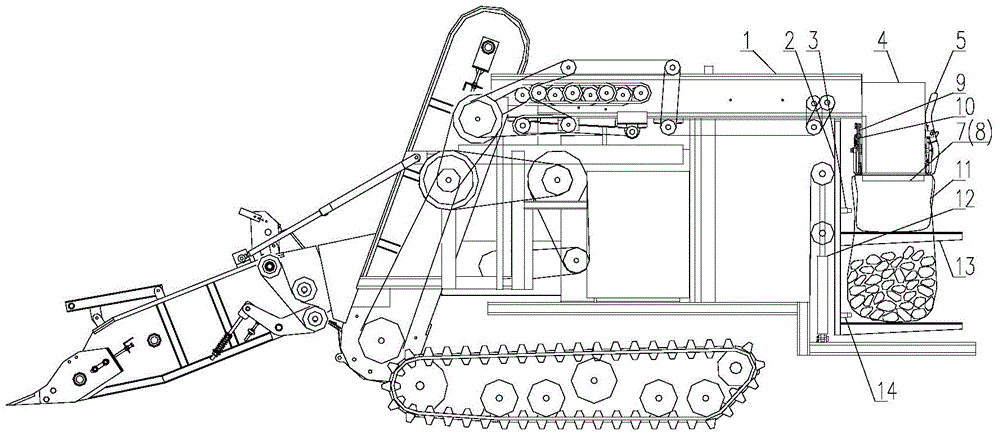

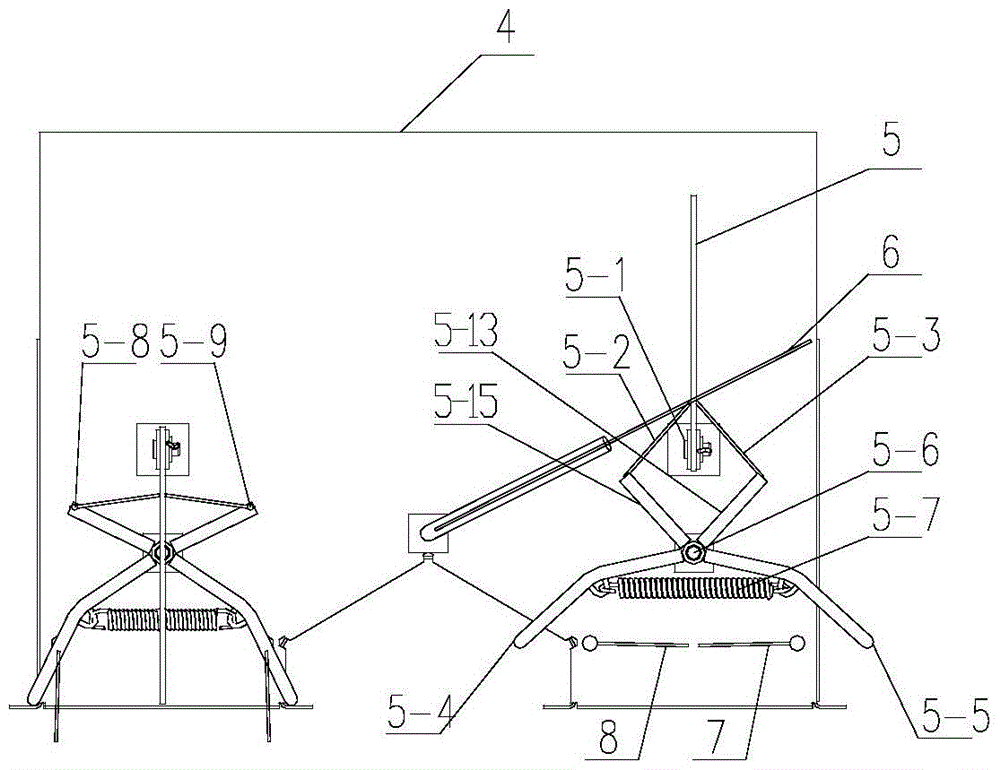

[0027] The potato synchronous bagging opening height self-adaptive bagging mechanism of this embodiment is as follows: Figure 1 to Figure 5 As shown, it includes a blanking transition bin 4 arranged on the rear frame 2 of the output end of the combine harvester 1 and a pier bag lifting platform 13 located below the blanking transition bin. Such as image 3 As shown, the bottom of the blanking transition chamber 4 has a left and right material inlet separated by a herringbone guide plate in the middle. Flap 6. The left and right feed openings are equipped with bag pressing mechanisms 5 respectively.

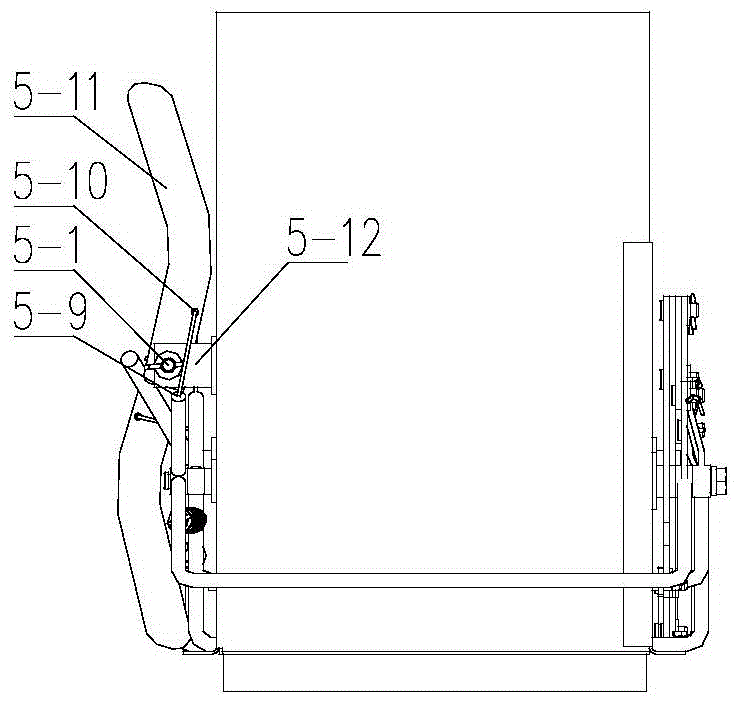

[0028] The bag pressing mechanism 5 includes a vertical handle 5-11 with upper and lower extreme positions. The lower end of the handle is hinged at the middle and upper part of the corresponding feeding port on one side of the blanking transition bin 4 through the hinge point 5-1. The handle The middle part of 5-11 has the perforation that passes steel wire stay cable, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com