Non-sewing material for a footwear upper, footwear upper and footwear using the same

A technology for shoe uppers and raw materials, applied in the field of shoe uppers and shoes, can solve the problems of waste of raw silk, waste of materials, loss of fabrics, etc., and achieve the effects of improving process efficiency, minimizing defective rate, and preventing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

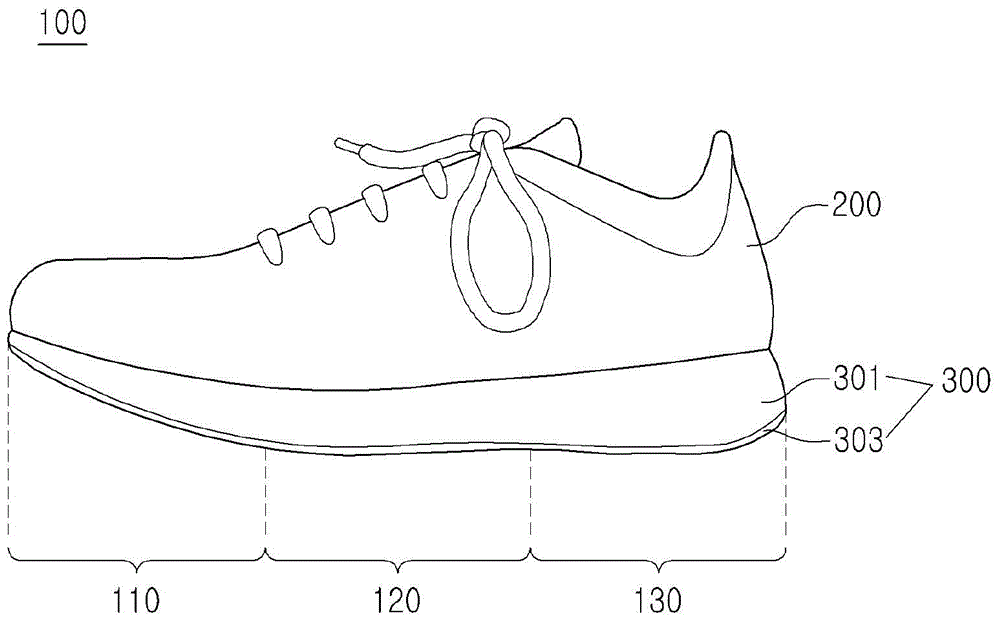

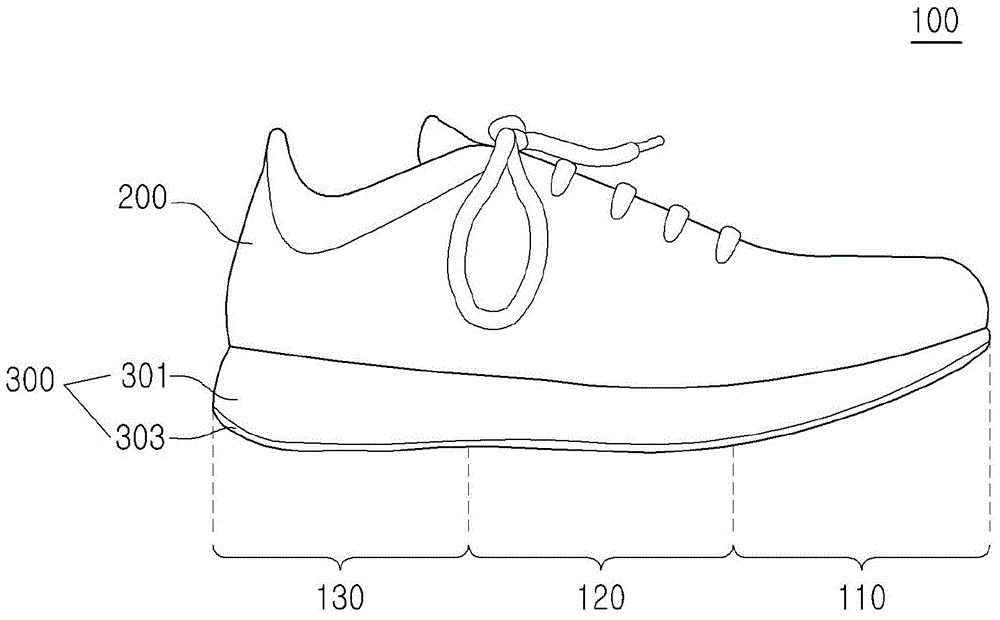

[0024] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0025] When attaching reference signs to components in each drawing, care should be taken to give the same components the same reference signs as much as possible even if they are shown in different drawings. In addition, in the description of the present invention, when a specific description of a known configuration or function may unnecessarily obscure the gist of the present invention, the detailed description will be omitted.

[0026] In addition, in describing the constituent parts of the present invention, terms indicating directions such as left side and right side may be interchanged depending on the reference, and inner and outer parts may also be changed based on the reference. In addition, terms such as first, second, A, B, (a), and (b) may be used when describing components of the present invention. Such terms are used only to distin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com