Railway wheelset press-fitting mechanism with end surface of axle as benchmark

A railway wheel and benchmark technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of excessive pressure data and control system data errors, deformation, waste of human and material resources, etc., to eliminate measurement errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be described below in conjunction with specific embodiments.

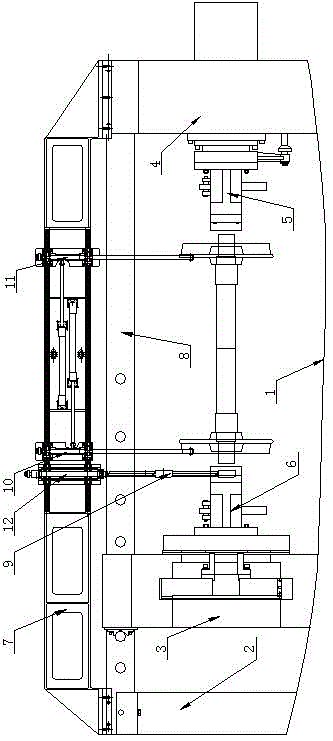

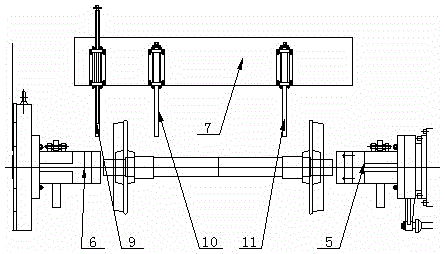

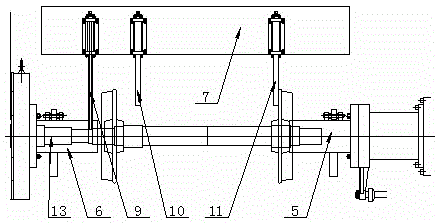

[0020] Such as Figure 1 to Figure 5 As shown, it is a structural schematic diagram of a railway wheel set press-fitting mechanism based on the axle end face of the present invention. According to the present invention, a railway wheel set pressing mechanism based on the axle end face comprises: a main pressure head 5 and an auxiliary pressure head 6 arranged coaxially and facing each other, along the direction parallel to the main pressure head 5 and the auxiliary pressure head 6 The reference measuring rod 9, the right floating measuring rod 11 and the left floating measuring rod 10 of the orbital movement of the axis, the reference measuring rod 9 is used to follow the movement of the axle end face, and the left floating measuring rod 10 is used to follow the wheelset The inner side of the left wheel moves, and the right floating measuring rod 11 is used to follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com