Chassis of low-floor trailer body

A low-floor, car body technology, applied to the underframe, railway car body parts, transportation and packaging, etc., can solve the problem of increasing the weight of the car body underframe, increasing the traction capacity, and poor force transmission performance of the car body underframe. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

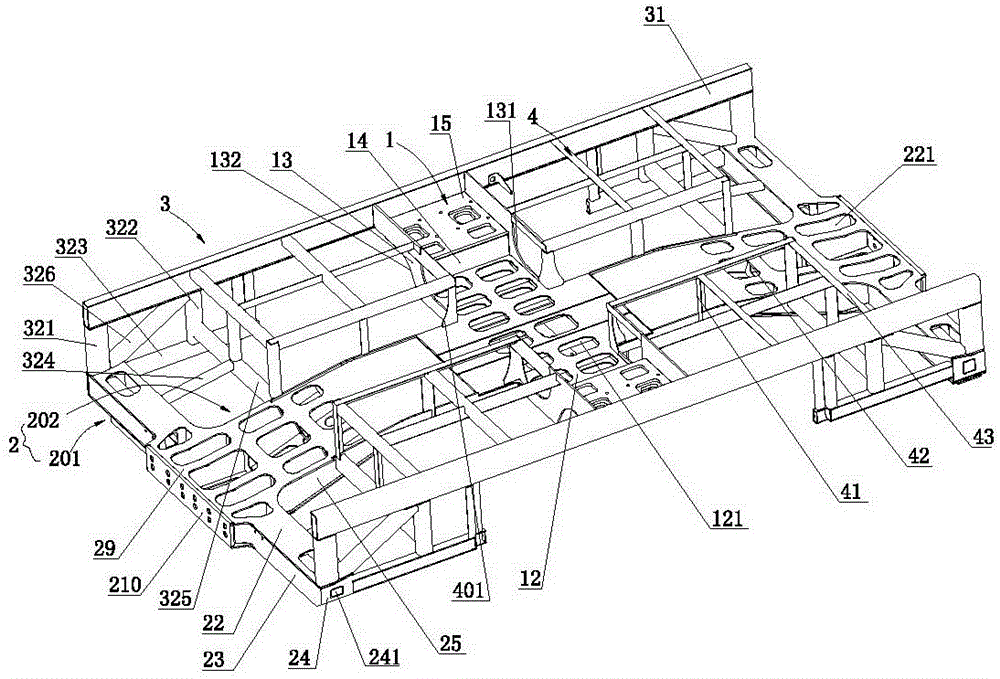

[0026] Such as Figure 1 to Figure 5 As shown, the chassis of the low-floor trailer body includes a corbel 1, a longitudinal beam 2, a side beam 3, a seat support beam 4, a middle seat 5, a traction connecting seat 6 and a transverse shock absorbing connecting seat 7.

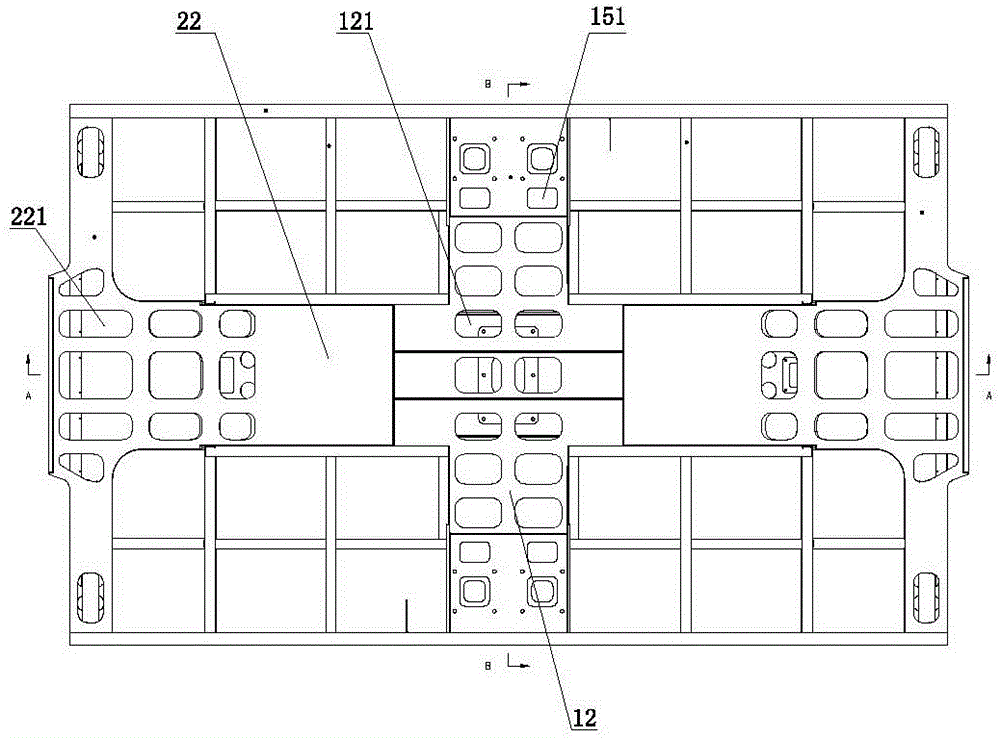

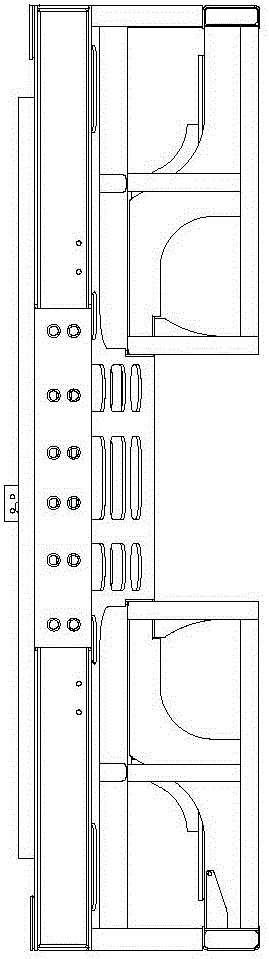

[0027] Such as figure 1 , figure 2 and Figure 5 As shown, the corbel 1 transversely runs through the entire vehicle body;

[0028]The corbel upper cover 12 is located above the corbel lower cover 11; the corbel lower cover 11 is provided with more than two first hollows 111, and the corbel upper cover 12 is provided with more than two first hollows. Two hollow out 121, to reduce the weight of corbel 1, and can not influence the strength and rigidity of corbel; Be provided with corbel rib 16 between corbel lower cover plate 11 and corbel upper cover plate 12, cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com