Chain type automatic steel counting and separating equipment in rod production line

A production line and chain-type technology, applied in the field of chain-type automatic steel counting and steel-separating equipment for bar production lines, can solve the problems of high steel-separating error rate, low cost, and difficult maintenance, and achieve low failure rate, accurate counting, and maintenance simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

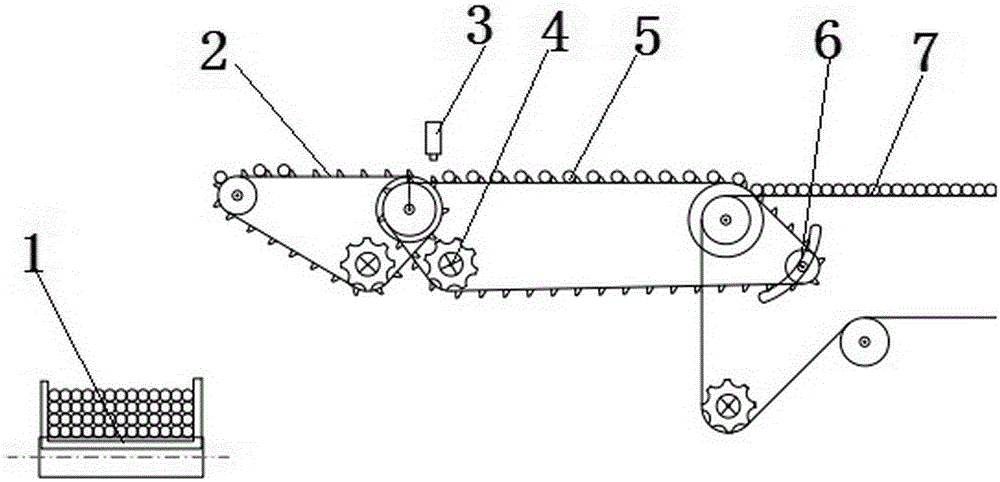

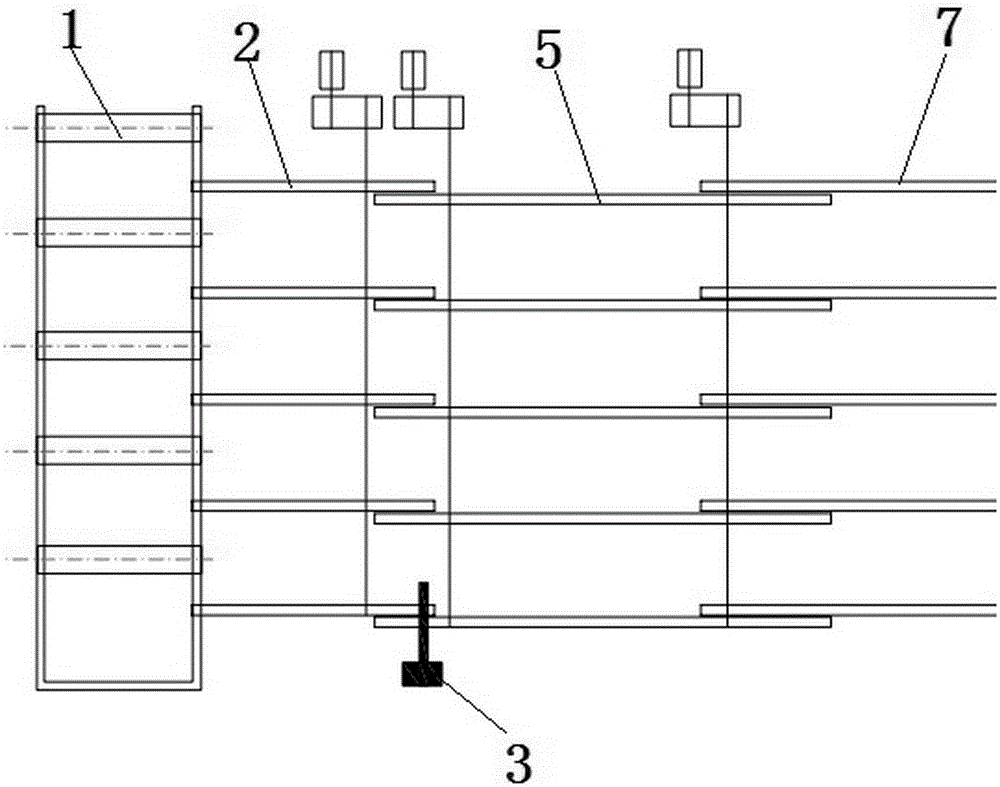

[0009] A chain-type automatic steel counting and steel-separating equipment for a bar production line, such as figure 1 , figure 2 As shown, a four-stage variable frequency and speed-regulated conveying chain is adopted, and the four-stage chain is driven by an independent motor 4, and the first two stages are speed-increasing plane conveying chains 7, and the finished bars are transported on the first two conveying chains Open the distance in the center; the last two sections are stepped toothed transport chains, the surface of the transport chain is evenly spaced with teeth, the running speed of the last two sections of the chain is the same, and the photoelectric counter 3 is installed on the third section of the chain 5 and the fourth section of the chain. Between the segment chains 2, when the counter reaches the set value, the third segment of the chain stops working, and the fourth segment of the toothed transport chain transports all the straight bars to the collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com