Sinker triangle structure for adjustable and energy-saving sinker device of single-double system flat knitting machine

A triangular structure, adjustable technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problem of not applying the Xinke triangular structure, and achieve the effect of simple structure, unique concept, and guaranteeing the accuracy of the guiding position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0027] Example.

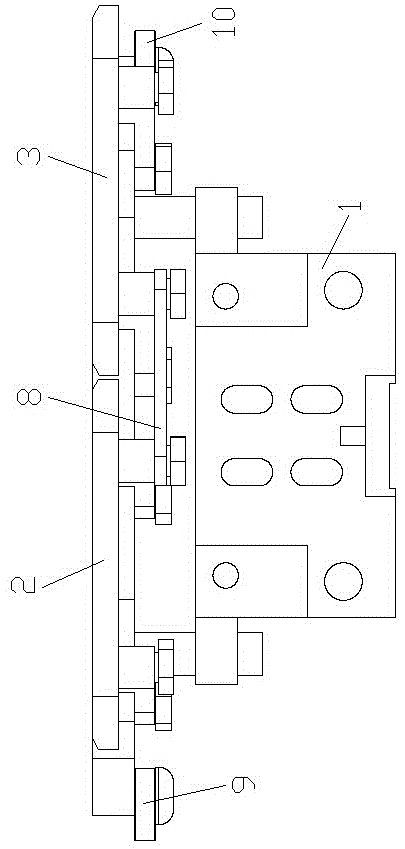

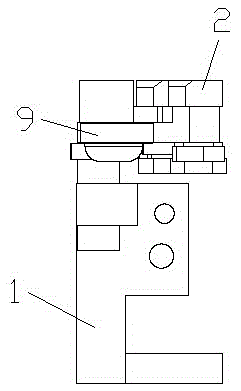

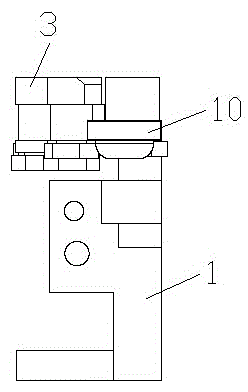

[0028] see Figure 1 to Figure 9 , the single and double system flat knitting machine in this embodiment can adjust the Sink triangle structure of the Sink triangle device to include the base 1, the left Sink triangle 2, the right Sink triangle 3, and the left Sink triangle 2 for swinging left and right. Rocker 4, right rocker 5 for swinging right Sink triangle 3 left and right, left magnetic part 6, right magnetic part 7, linkage lever 8 for left Sink triangle 2 and right Sink triangle 3 to generate linkage, use It is used for the left anti-collision member 9 which plays the role of anti-collision buffer in the left and right swing process of the left Sink triangle 2 and the right anti-collision ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap