Multi-mode fishing net knitting machine movement mechanism

A technology of motion mechanism and knitting machine, applied in the direction of knitting fabric, mechanical equipment, transmission device, etc., can solve the problems of poor stability, incapable of different motion output, large size, etc., to ensure stability, high-precision transmission, and small size of the mechanism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

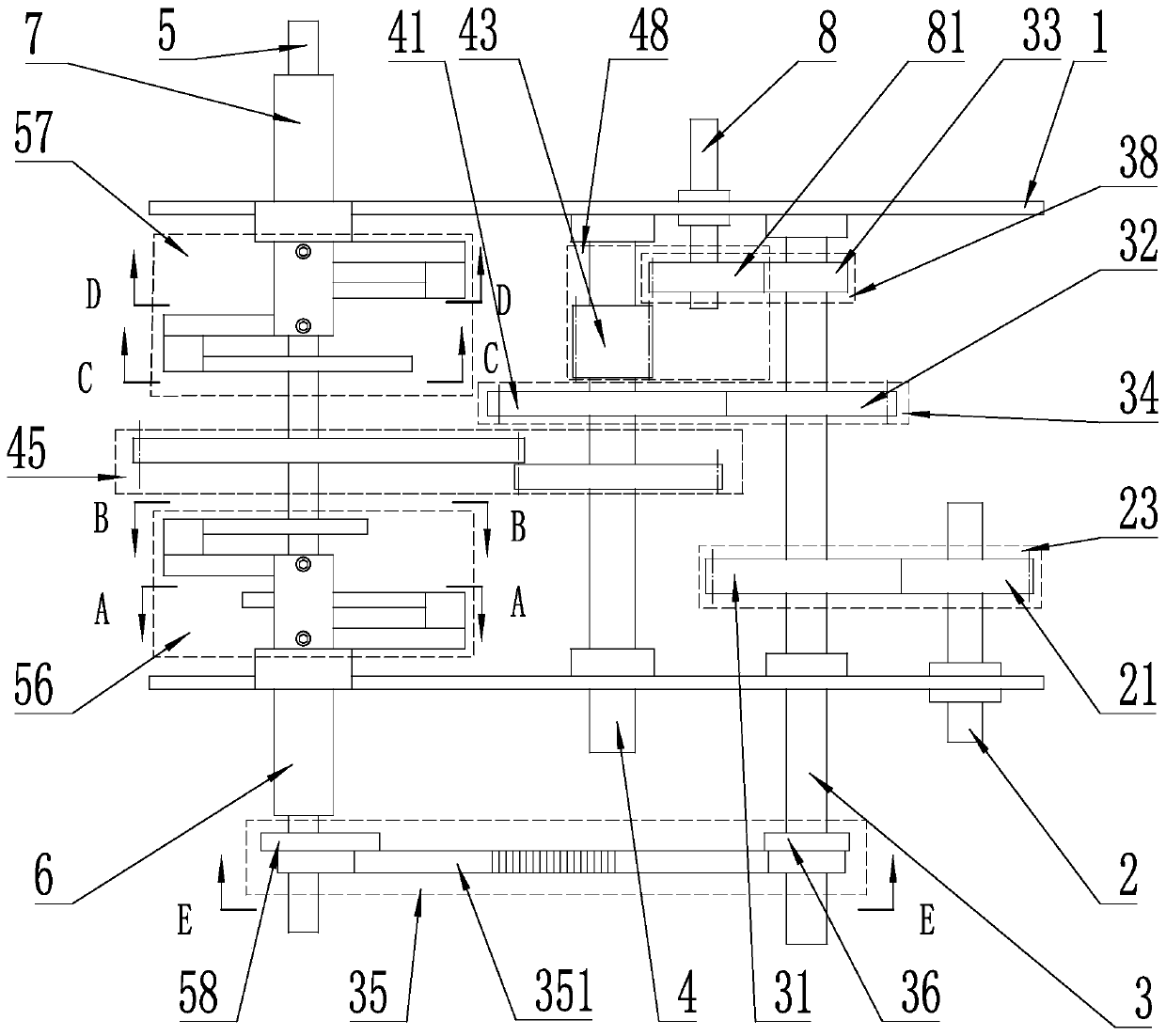

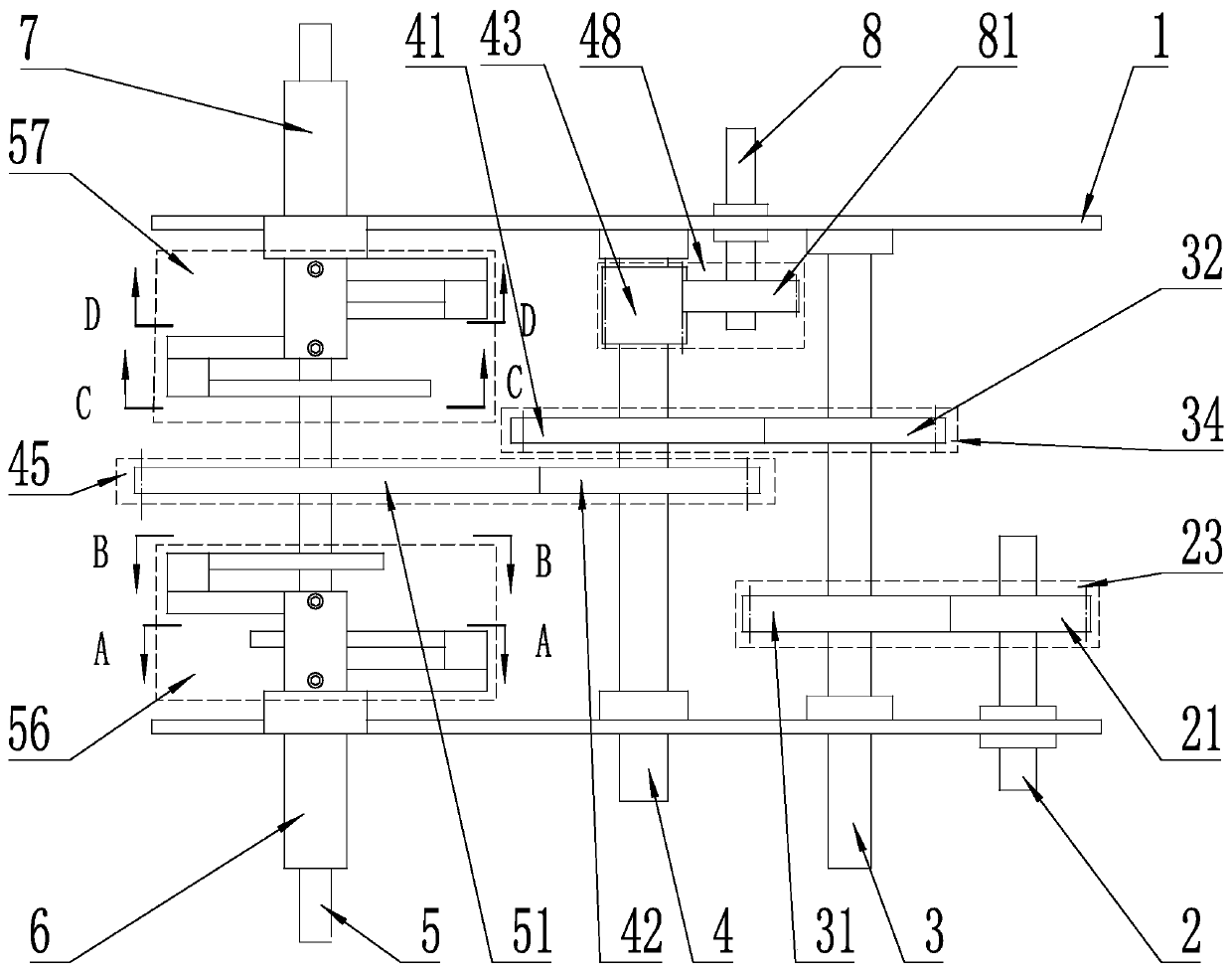

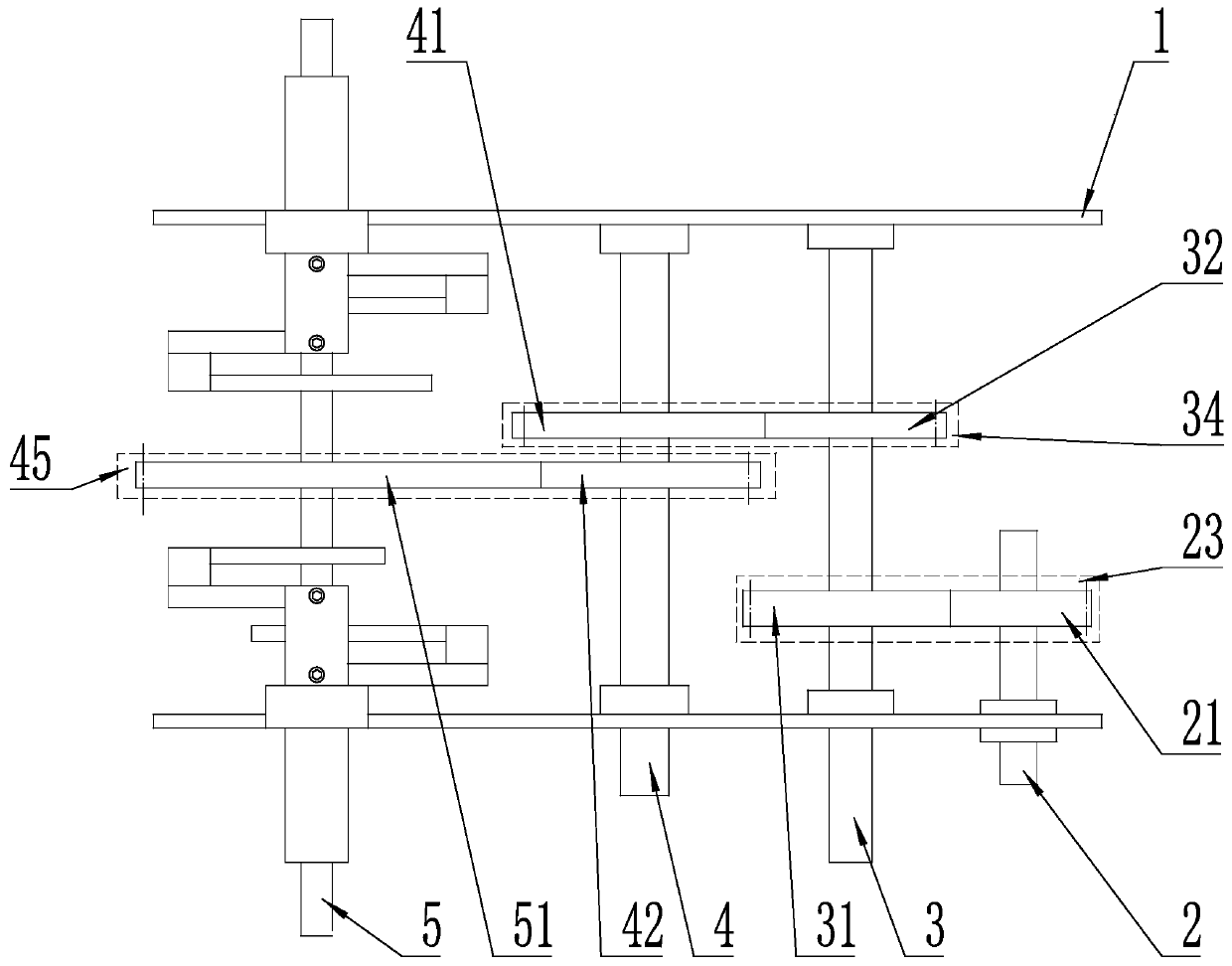

[0030] Such as figure 1 As shown, a multi-mode fishing net knitting machine movement mechanism includes a box body 1, a driving shaft 2, a driven shaft a3, a driven shaft b4, a driven shaft c5, a driven shaft d6, a driven shaft e7, and a driven shaft f8, gear transmission mechanism a23, gear transmission mechanism b34; said driving shaft 2, driven shaft a3, driven shaft b4, driven shaft c5, driven shaft d6, driven shaft e7, driven shaft f8, gear transmission The mechanism a23 and the gear transmission mechanism b34 are installed on the box body 1 respectively. The driving shaft 2 is connected to the driven shaft a3 through the gear transmission mechanism a23; the driven shaft a3 is connected to the driven shaft b4 through the gear transmission mechanism b34.

[0031] The gear transmission mechanism a23 includes an input gear a21 and an output gear a31. The input gear a21 is sleeved on the driving shaft 2 and meshes with the output gear a31 sleeved on the driven shaft a3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com