Light Filter, Optical Module, And Electronic Device

A technology of electronic equipment and optical filters, applied in optics, optical components, instruments, etc., can solve problems such as stress difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

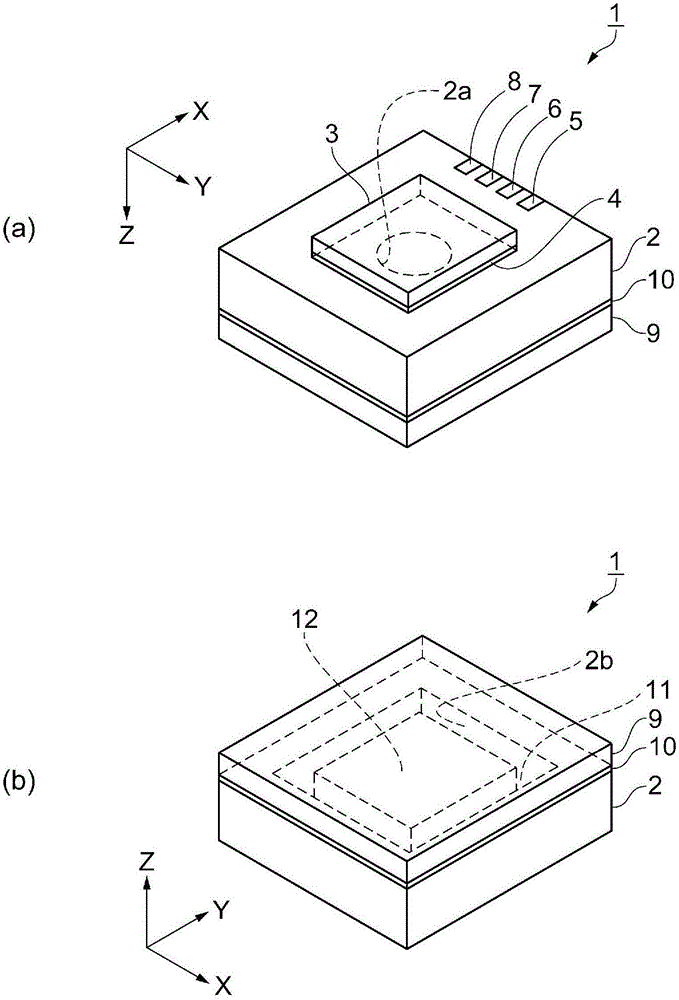

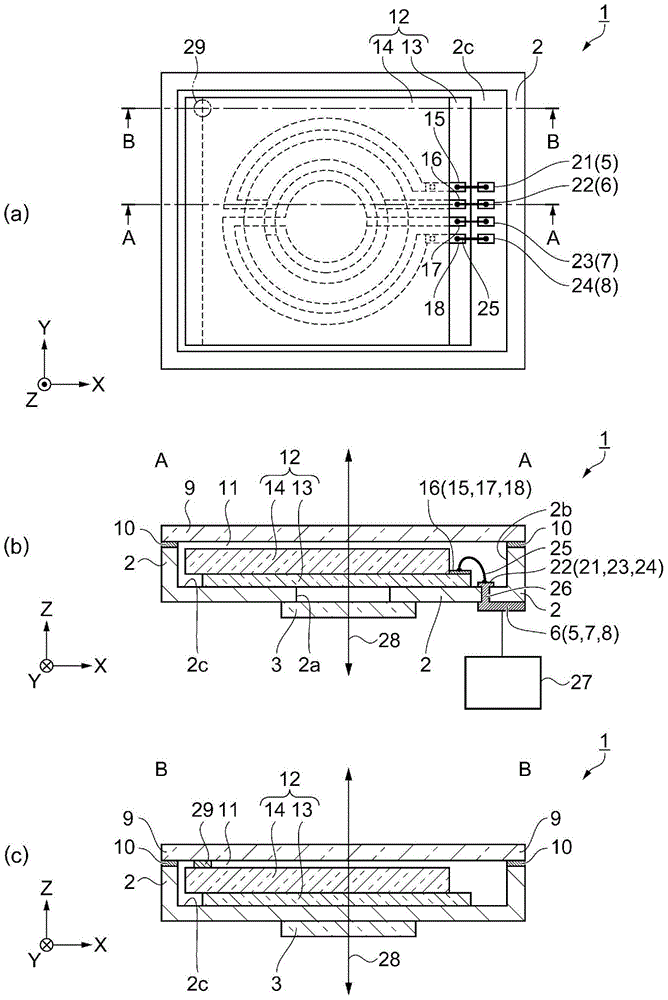

[0058] In this embodiment, an optical module having a characteristic structure and a method of manufacturing the optical module will be described with reference to the drawings. refer to Figure 1 to Figure 8 , to describe the optical module. figure 1 (a) and figure 1 (b) is a schematic perspective view showing the structure of the optical module. figure 1 (a) is a view viewed from the first cover side of the optical module, figure 1 (b) is a view seen from the second cover side of the optical module. Such as figure 1 As shown in (a), the optical module 1 has a substantially rectangular parallelepiped shape. Let the downward direction in the figure of the optical module 1 be the Z direction, and let the two directions perpendicular to the Z direction be the X direction and the Y direction. The X direction, the Y direction, and the Z direction are directions along the sides of the optical module 1 , which are orthogonal directions.

[0059] The optical module 1 includes ...

no. 2 approach

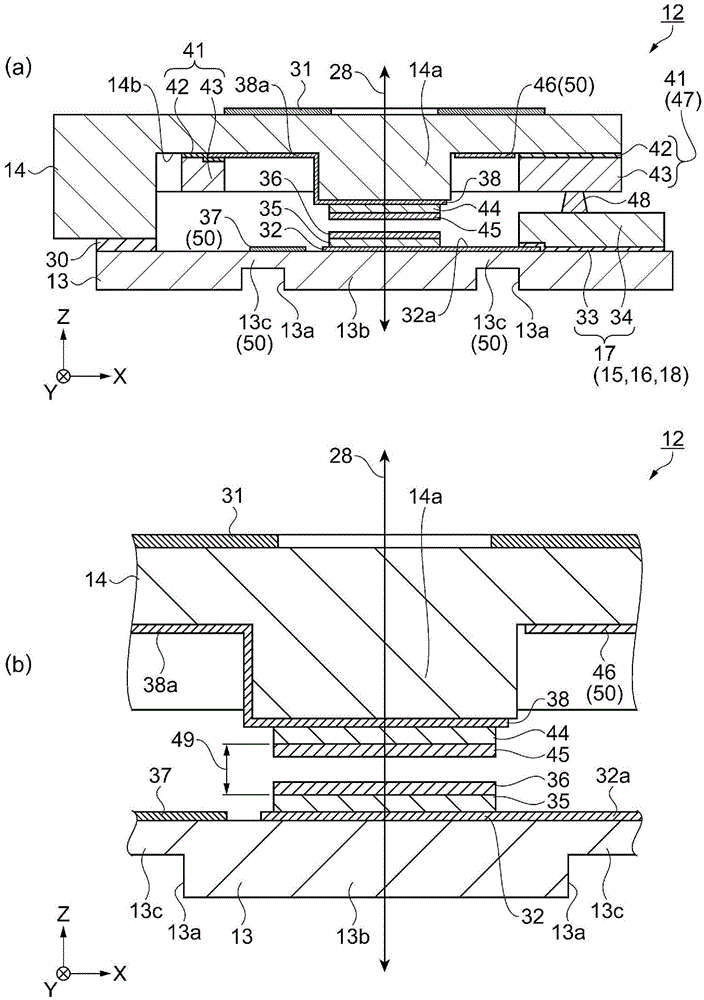

[0144] Next, use Figure 9 and Figure 10 One embodiment of an optical module will be described. Figure 9 (a) is a schematic plan view showing the structure of the movable substrate, Figure 9 (b) is a schematic plan view showing the structure of the fixed substrate. Figure 10 It is the electrical control block diagram of the control part. This embodiment differs from the first embodiment in that the movable reflective film 35 and the fixed reflective film 44 are electrically connected within the filter. In addition, descriptions of the same points as those in the first embodiment are omitted.

[0145] That is to say, in this embodiment, if Figure 9 As shown, the optical module 60 includes an optical filter 61 in which the movable substrate 13 and the fixed substrate 14 are bonded via the bonding film 30 . A conductive film 32 is provided on the movable substrate 13 , and a movable reflective film 35 and a protective film 36 are provided to overlap on the conductive f...

no. 3 approach

[0153] Next, use Figure 11 A first embodiment of the optical module will be described. Figure 11 This is a schematic sectional view of main parts showing the structure of the reflective film. This embodiment differs from the first embodiment in that the materials of the conductive film and the protective film are different. In addition, descriptions of the same points as those in the first embodiment are omitted.

[0154] That is to say, in this embodiment, if Figure 11 As shown, the optical module 66 includes an optical filter 67 in which the movable substrate 13 and the fixed substrate 14 are bonded via the bonding film 30 . A conductive film 68 is provided on the movable substrate 13 , and the movable reflection film 35 and the protective film 69 are provided to overlap on the conductive film 68 . The conductive film 70 is provided on the fixed substrate 14 , and the fixed reflective film 44 and the protective film 71 are provided to overlap on the conductive film 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com