Novel sewing table structure

A sewing table and a new type of technology, applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems affecting the operation of sewing frames or templates, cumbersome connection methods, and difficult assembly, avoiding production safety accidents, assembly debugging, etc. Simple, smooth-running effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

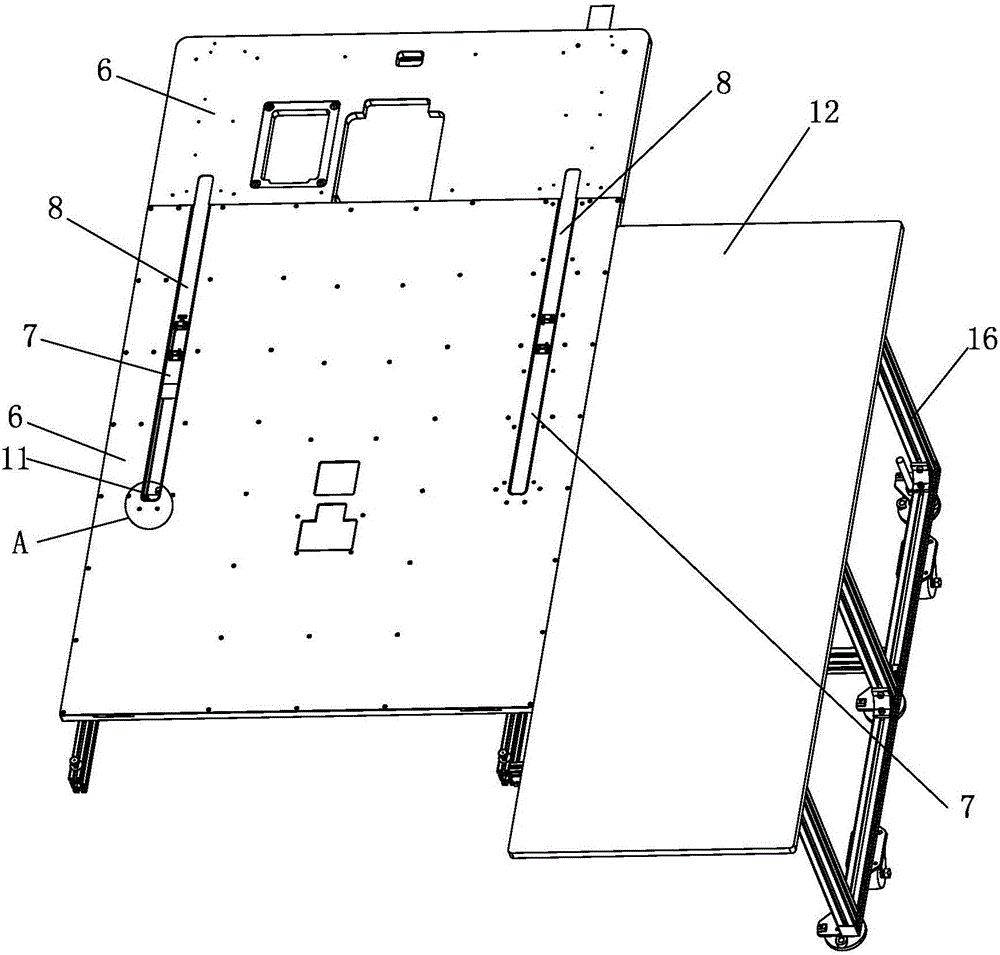

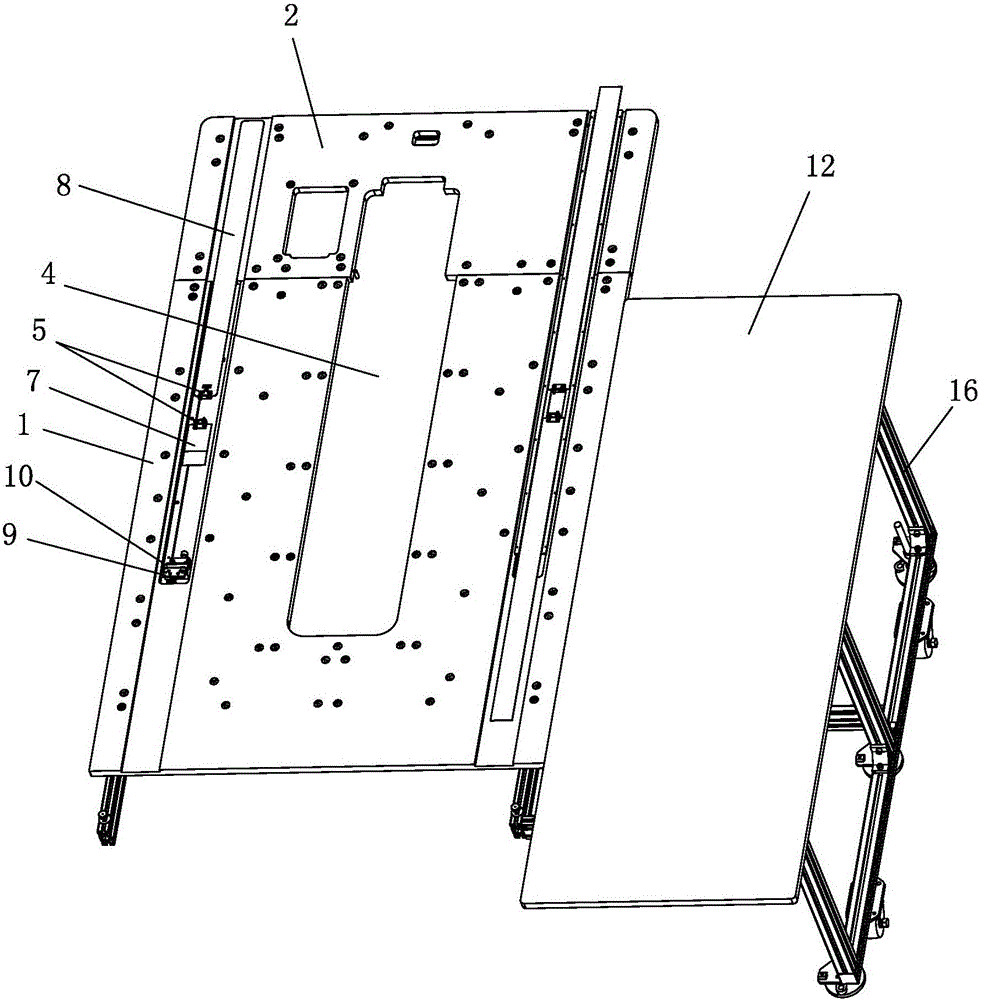

[0029] Embodiment 1: see figure 1 —4:

[0030] A new seam structure includes a base plate 1, and a rear base plate 2 is connected to the rear end of the base plate 1. Both the base plate 1 and the rear base plate 2 are made of wooden multilayer boards. The machine head installation hole 4 is arranged on the base plate and the rear base plate, and the bottom plane of the base plate 1 and the rear base plate 2 is fixed with a profile 3, and the profile 3 is connected with the frame, on the base plate 1 on the left and right sides of the machine head mounting hole 4 A slideway is provided, and the slideway extends to the rear base plate 2, and a slide plate reciprocating along the slideway is arranged in the slideway, and the two slide plates are connected with the moving beam through the mounting seat 5.

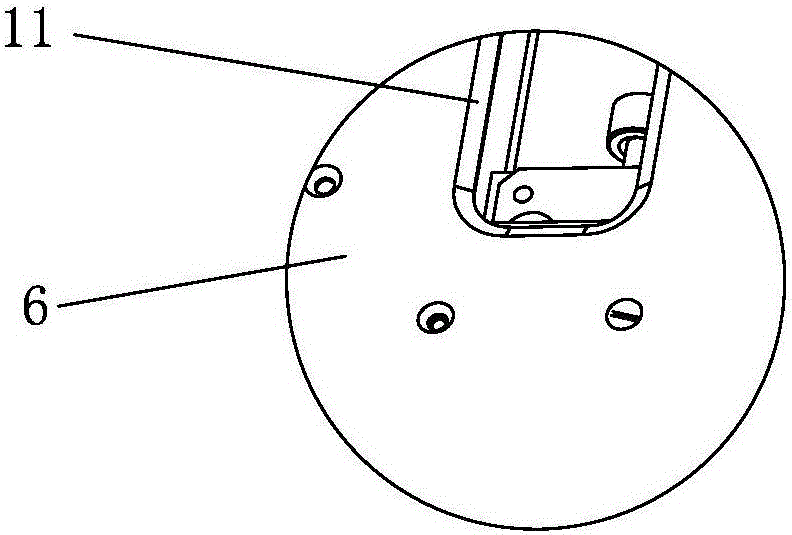

[0031] Both the above-mentioned base plate 1 and the rear base plate 2 are fixed with an integrated seam table 6 by screws, and the integrated seam table 6 is provided with s...

Embodiment 2

[0038] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is:

[0039] In this embodiment, the wooden substrate is directly used, that is, the surface is no longer covered with an integrated seam.

[0040] Correspondingly, a guide groove is provided on the slideway, and the slide plate is arranged in the guide groove and moves back and forth along the guide groove.

[0041] The end of the slideway close to the operator is provided with a guide block, including an upper guide block and a lower guide block. The upper guide block is fixed on the base plate, and the lower guide block is fixed on the frame. The bottom plane of the upper guide block and the lower guide block The upper planes of both are inclined planes, and the two inclined planes form downward guide grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com