A step-by-step direct-acting piston type high-pressure differential solenoid valve

A technology of solenoid valve and high pressure difference, which is applied to valve details, valve devices, engine components, etc., can solve the problems of the valve core not being opened and ordinary solenoid valves not being used normally, and achieve the effect of accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

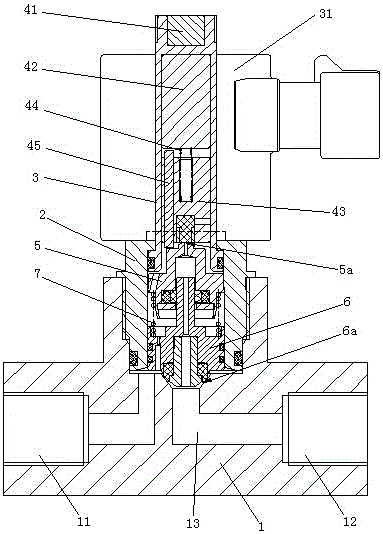

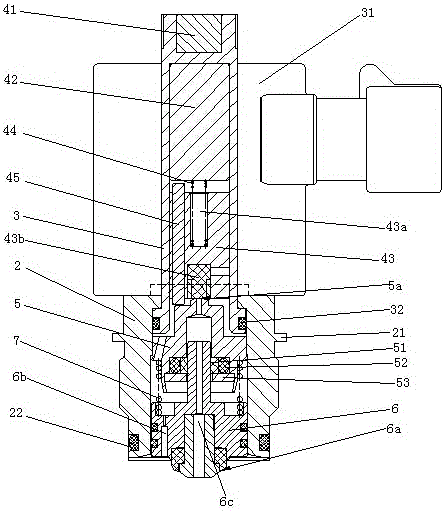

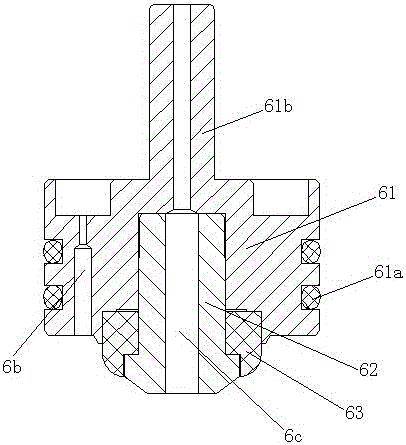

[0025] Such as Figure 1 to Figure 5 Shown is the structural representation of the present invention,

[0026] The reference signs are: valve body 1, air inlet 11, air outlet 12, air passage 13, valve seat 2, rib 21, valve seat sealing ring 22, casing 3, coil 31, casing sealing ring 32. Static iron core 41, first moving iron core 42, second moving iron core 43, spring groove 43a, first valve port gasket 43b, moving iron core spring 44, ejector rod 45, valve nozzle 5, first valve Port 5a, casing 51, valve mouth sealing ring 52, flat gasket 53, valve core assembly 6, second valve port 6a, pilot hole 6b, pressure relief hole 6c, piston rod 61, piston rod sealing ring 61a, valve core guide Column 61b, spool head 62, second valve port sealing gasket 63, spool spring 7.

[0027] Such as Figure 1 to Figure 5 as shown,

[0028] A step-by-step di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com