Microacoustic device and method for manufacturing

An acoustic and device technology, applied in the field of micro-acoustic devices, can solve problems such as hindering miniaturization and expensive technical measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

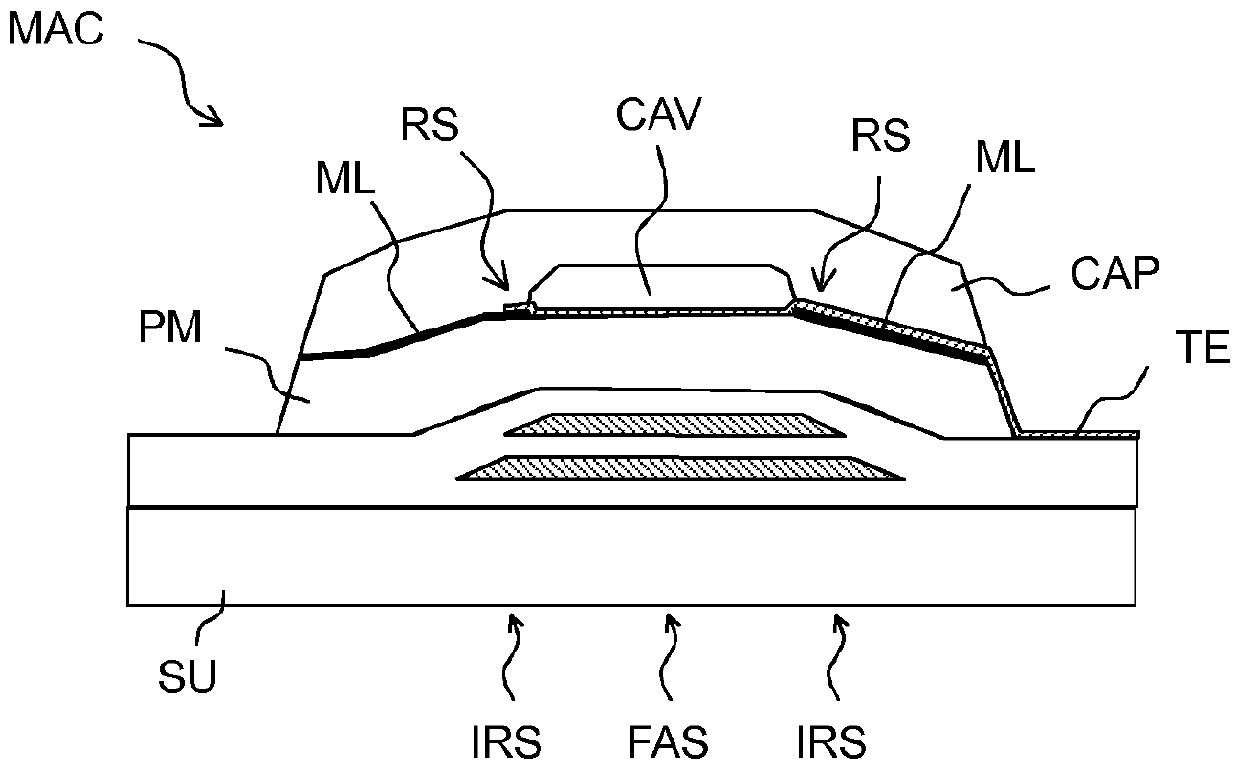

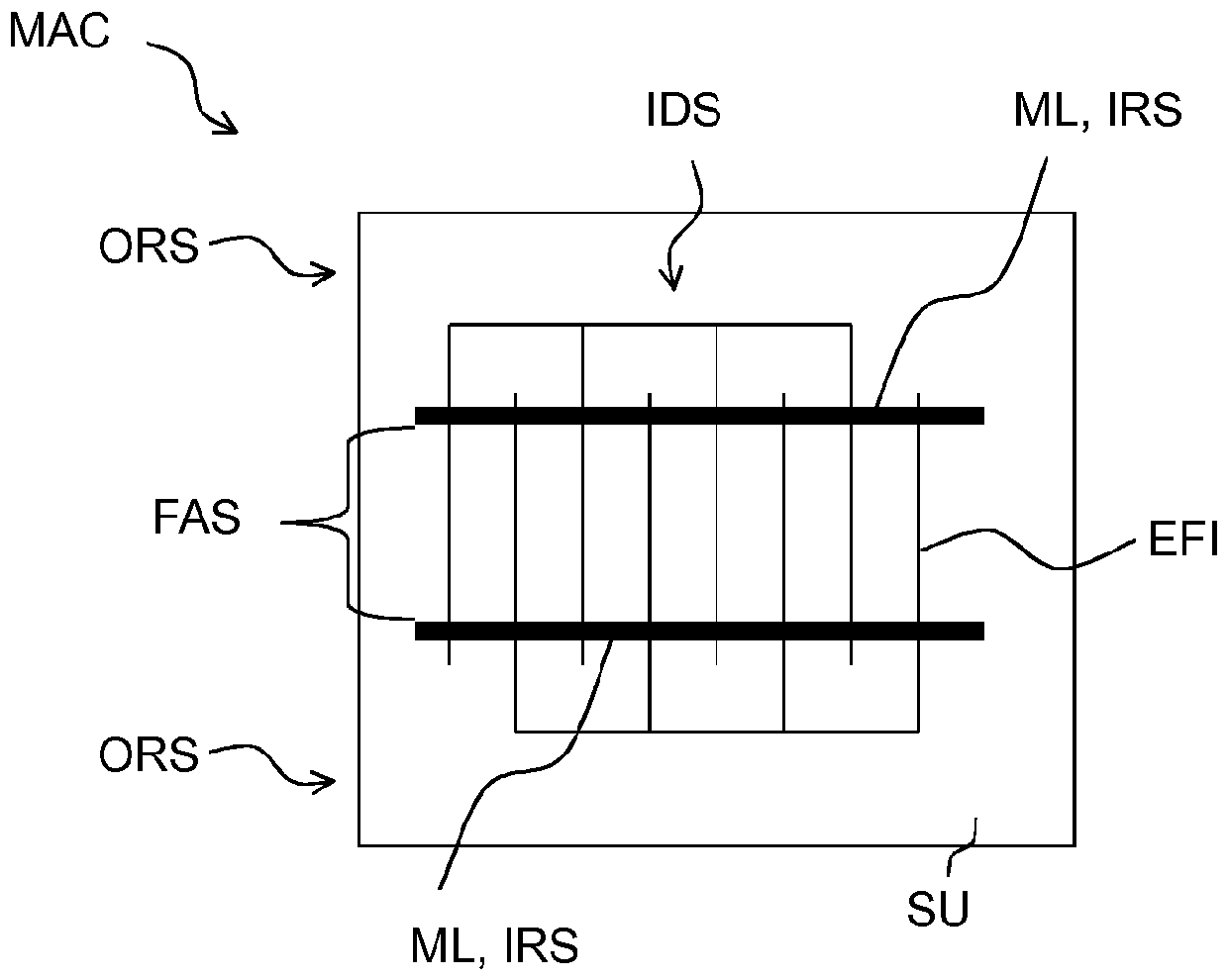

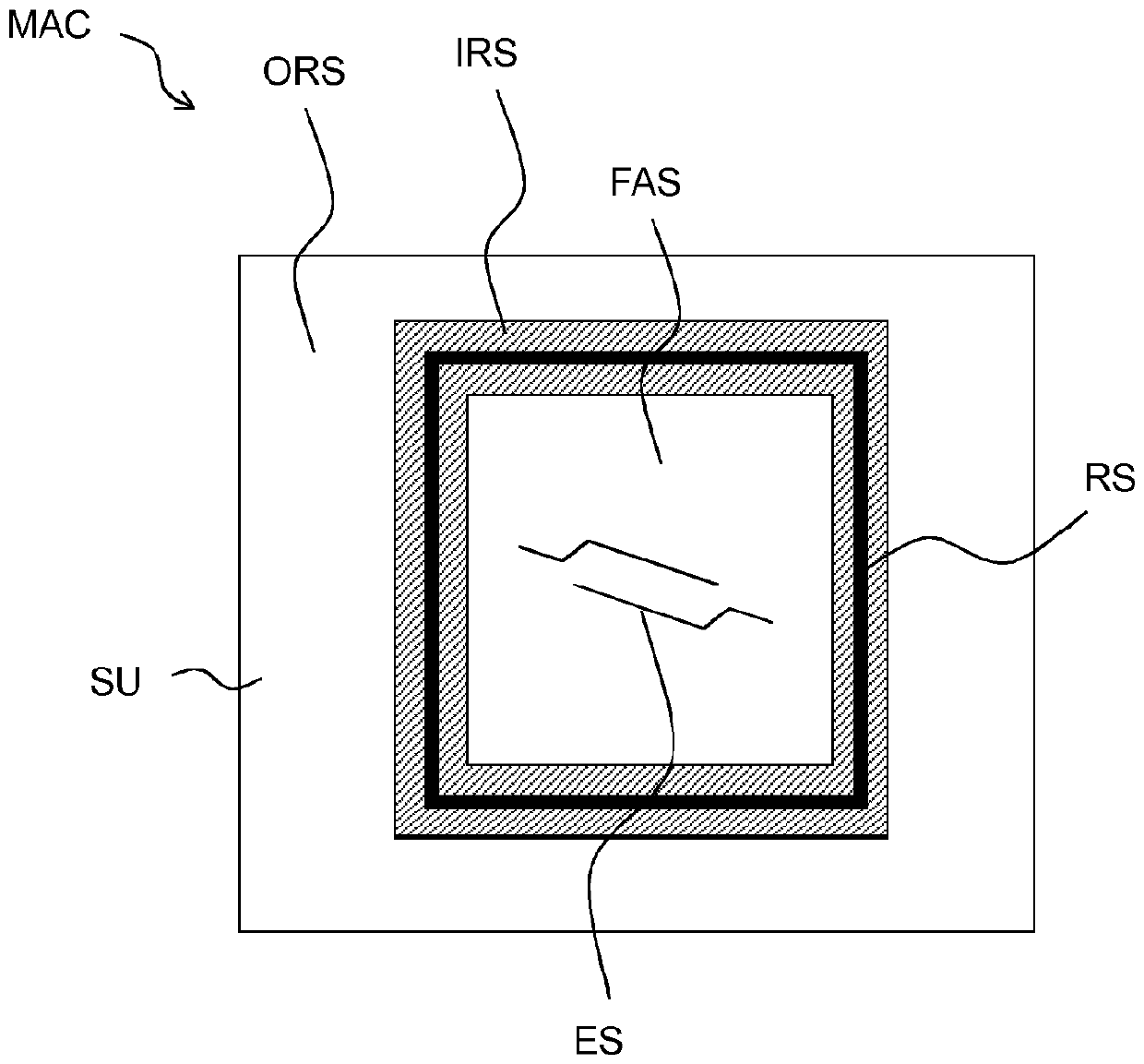

[0055] figure 1 The relationship between the acoustically functional area FAS, the inner edge area IRS and the outer edge area of the microacoustic device MAC is shown. Sound waves can propagate in the acoustically functional area FAS. Ideally, here as little acoustic energy as possible is radiated into the remaining regions of the component. Thus, the outer edge region ORS and the acoustically functional region FAS are substantially acoustically decoupled. figure 1 The lower part shows the amplitude AMP of the acoustic wave in the device. Ideally, the amplitude is substantially constant in the acoustically functional region and zero in the outer edge region ORS. In the intervening transition region, the inner edge region IRS, the amplitude drops. figure 1 The upper part of shows the corresponding technical characteristics of the device. The covering CAP is arranged over the structure of the acoustically functional area. The support area of the cover, ie the area wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com