Glass sheet with an enamel-based coatin

A glass plate, coating technology, applied in the direction of coating, thin material handling, transportation and packaging, which can solve the problems of damage to the first layer, low resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

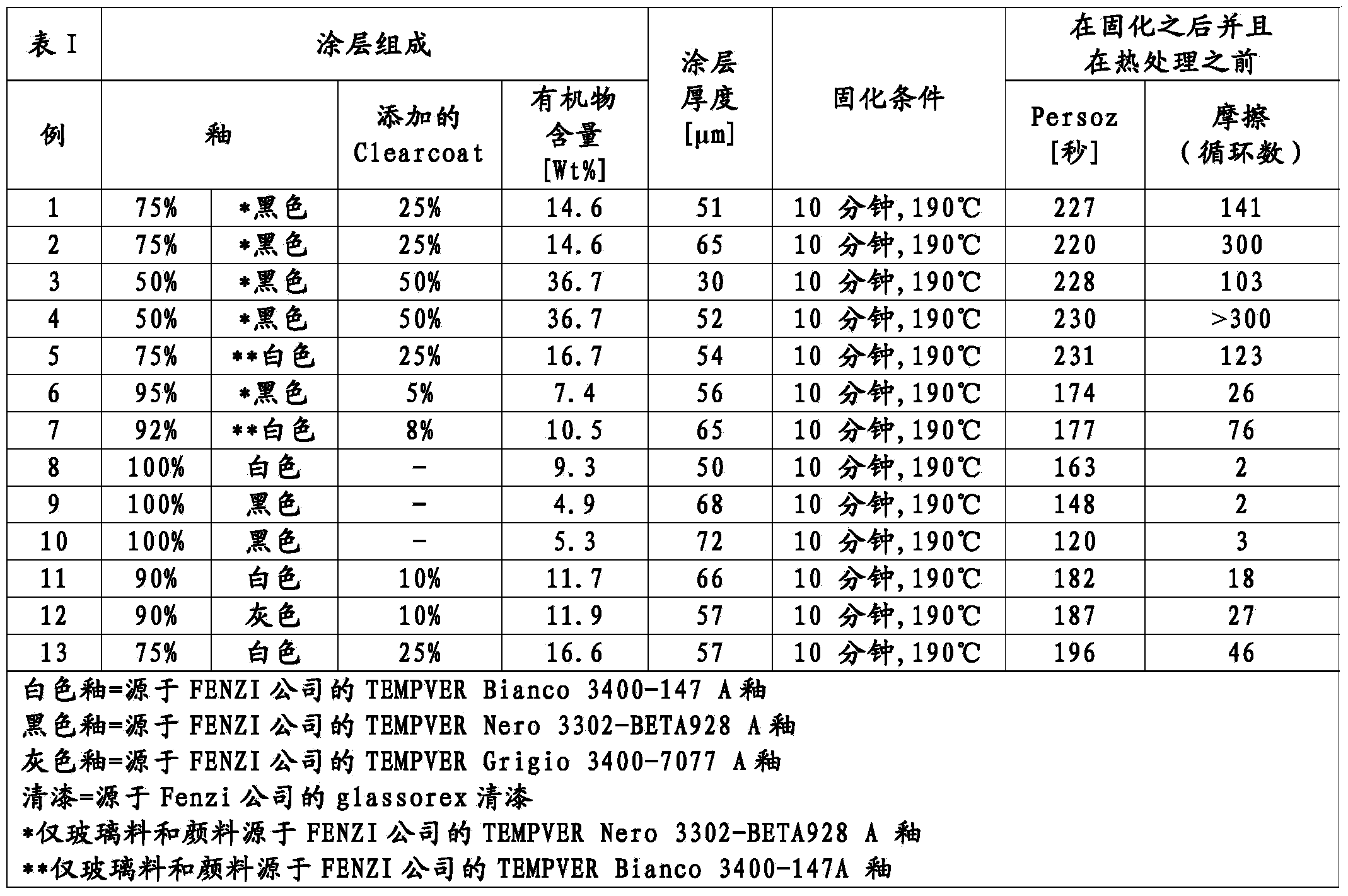

[0056] Embodiment 1-5 (according to the present invention)

[0057] First, a 4 mm thick clear float glass plate was washed in the usual way. It is then passed under the bar coater where it is covered with the glaze-based composition. It was then cured by temperature under the conditions described in Table I. Also given in Table I are the coating thicknesses once cured and before heat treatment.

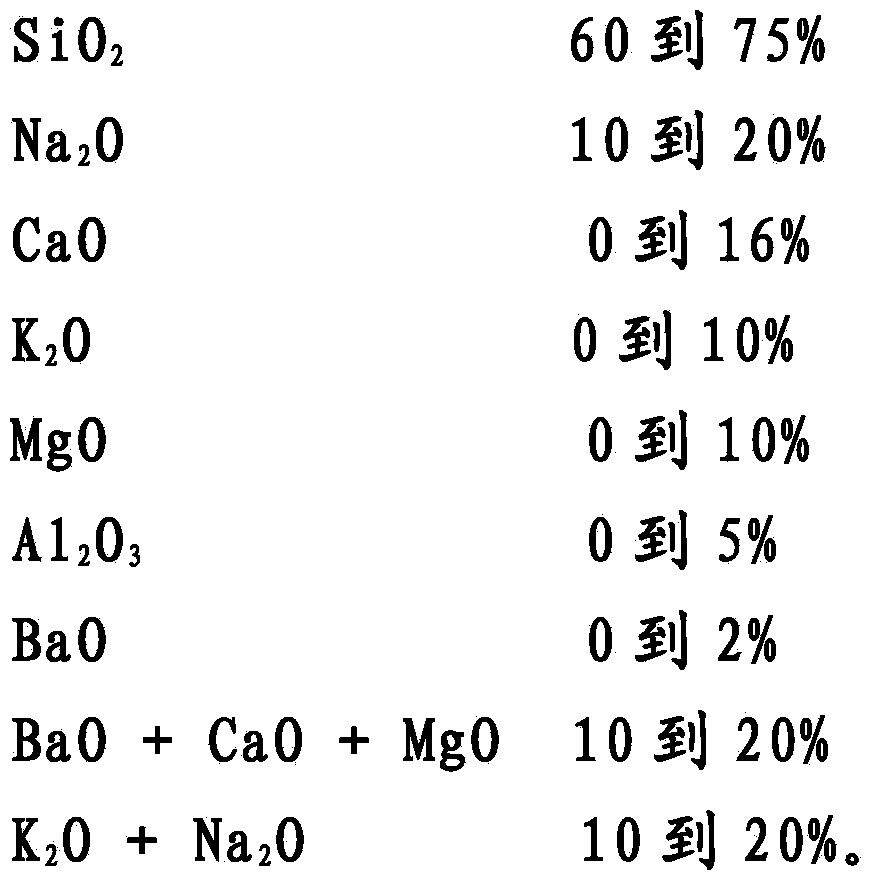

[0058] For each of Examples 1-5, the enamel-based coating composition deposited on the glass plate was 25-50 wt% of commercial paint (from FENZI company's Clearcoat (varnish)) added to 50-75 wt% of Glass frit and pigments are in and thoroughly mixed with the glaze in order to increase the content of reactive organic materials in the medium. The Clearcoat contains methacrylic resin, melamine resin and epoxy resin. Thus, the medium is enriched in crosslinkable compounds, ie reactive organic compounds. "Reactive organic compound" is understood to mean an organic material which will...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com