Stone surface covering

A stone and multi-layer material technology, applied in floor coverings, building elements, natural mineral layered products, etc., can solve problems such as limiting the application of floor and wall decoration, hindering use, etc., to improve mechanical resistance, impact resistance The effect of high, low refractory properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

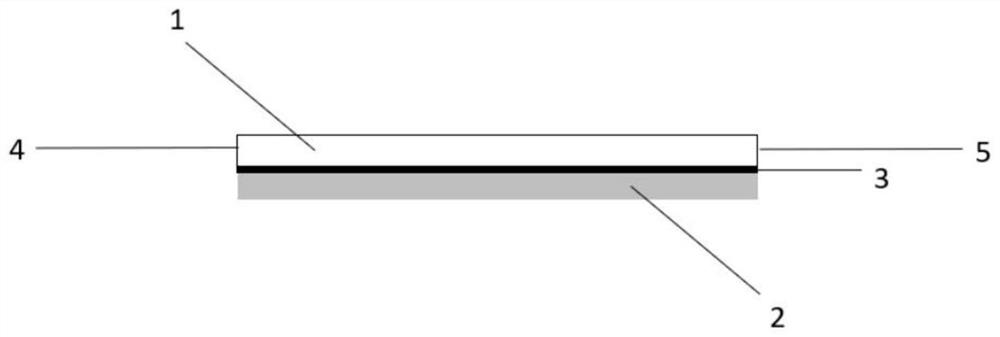

Embodiment 1

[0080] We produced as figure 1Described multilayer material, to obtain a 100cm * 115cm big, 8.25mm thick material, this material is made of 6mm thick gray marble 1, 0.25mm thick two-component epoxy adhesive layer 3 and 2mm thick muscovite layer 2 composition. We first glued a 18mm thick, 100cm x 120cm large marble 1 on its two larger surfaces with two separate 100cm x 120cm large, 2mm thick mica layers 2, each made of 10% epoxy adhesive And muscovite-type mica flakes. Then we use 400N / m 2 The glue was pressed and cured at room temperature for 6 hours. The glue we use is a two-component glue with a viscosity of 10,000cps to 14,000cps and a solid content of 95%. We then sawed the multilayer material by cutting the marble from its edge with a diamond saw at a speed of 0.5 m / min to provide 2 pieces of marble-mica layer multilayer material 1 of 100 cm x 120 cm. We then ground stone layer 1 and polished it to give each layer a smooth and adjusted surface thickness.

Embodiment 2

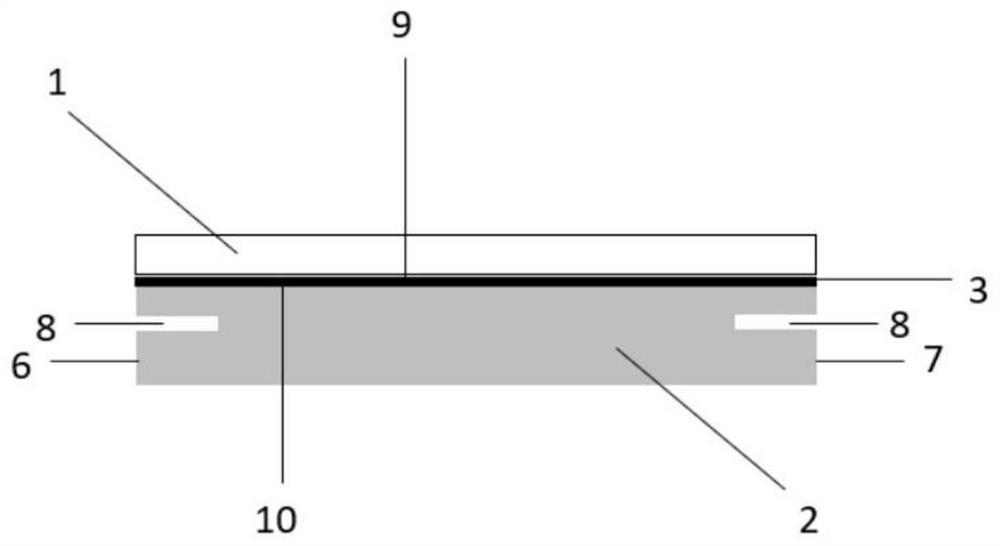

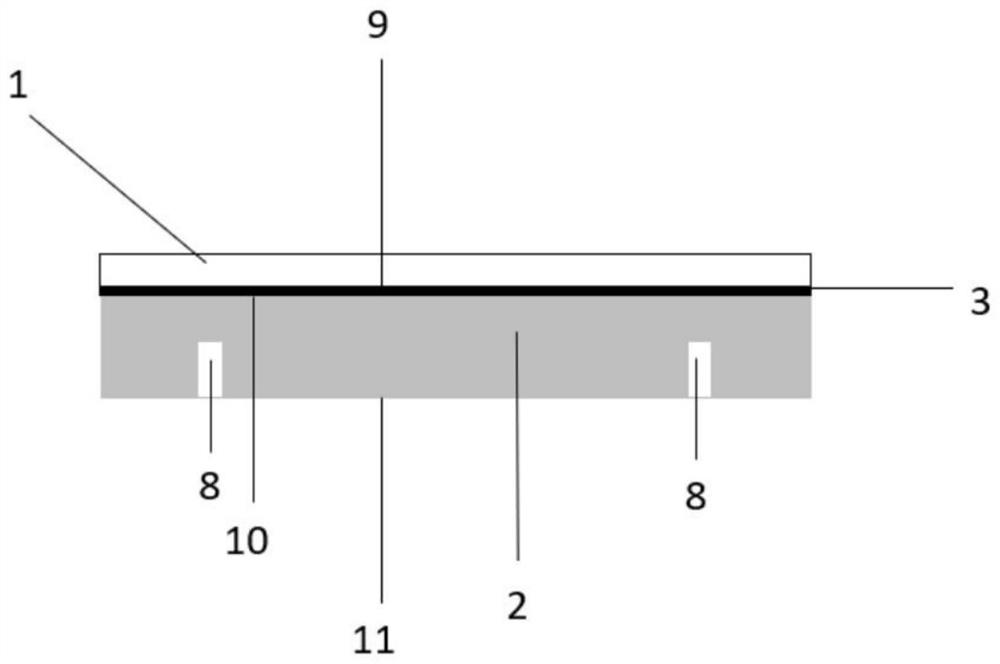

[0082] We produced as image 3 Described multilayer material, to obtain a 20cm * 115cm big, 16.15mm thick material, this material is made of 6mm thick gray marble 1, 0.15mm thick two-component epoxy adhesive layer 3 and 10mm thick muscovite layer 2 composition. We glued a 18mm thick, 100cm x 120cm large marble 1 on its two larger surfaces two 10mm thick mica layers 2 consisting of 12% epoxy adhesive and muscovite mica flakes . Then we use 400N / m 2 The glue was pressed and cured at 20°C for 24 hours. The glue we use is a two-component glue with a viscosity of 10,000cps to 14,000cps and a solid content of 95%. We then sawed the multilayer material by cutting the marble 1 from its edge with a diamond saw at a speed of 1 m / h to provide 2 pieces of marble-mica layer multilayer material of 100 cm x 120 cm. We grind and polish the stone layer 1 to provide a smooth and adjusted surface thickness. We then cut the obtained multilayer material into pieces of 20cm x 115cm with a sto...

Embodiment 3

[0085] We performed impact tests on several samples to evaluate the crack resistance of some embodiments of the present invention to compare their performance with samples of stone thicknesses and stone-honeycomb aluminum and stone-PVC multilayer material structures commonly found in the market .

[0086] We evaluated the fracture resistance of the samples by gradually dropping spherical steel balls from gradually increasing heights on the stone surface of the samples and observing whether the stone tile layer cracked. With the exception of 2 modifications to increase the relevance of the test results to the material of the invention, we carried out the conditions described in the standard EN 14617-9:2005 (Impact resistance of flat products made of reconstituted stone) experiment method. These two modifications in the EN 14617-9:2005 test method are:

[0087] 1. The test method described in EN 14617-9:2005 considers hitting the center of the sample accurately at the same poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com