Ceramics processing

A technology of ceramic green body and ceramic honeycomb, which is applied in the field of extruding ceramic composition and drying ceramic green body, can solve the problems of deformation or leakage, low mechanical resistance, low adhesion of ceramic skin composition, etc., to reduce leakage and/or deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

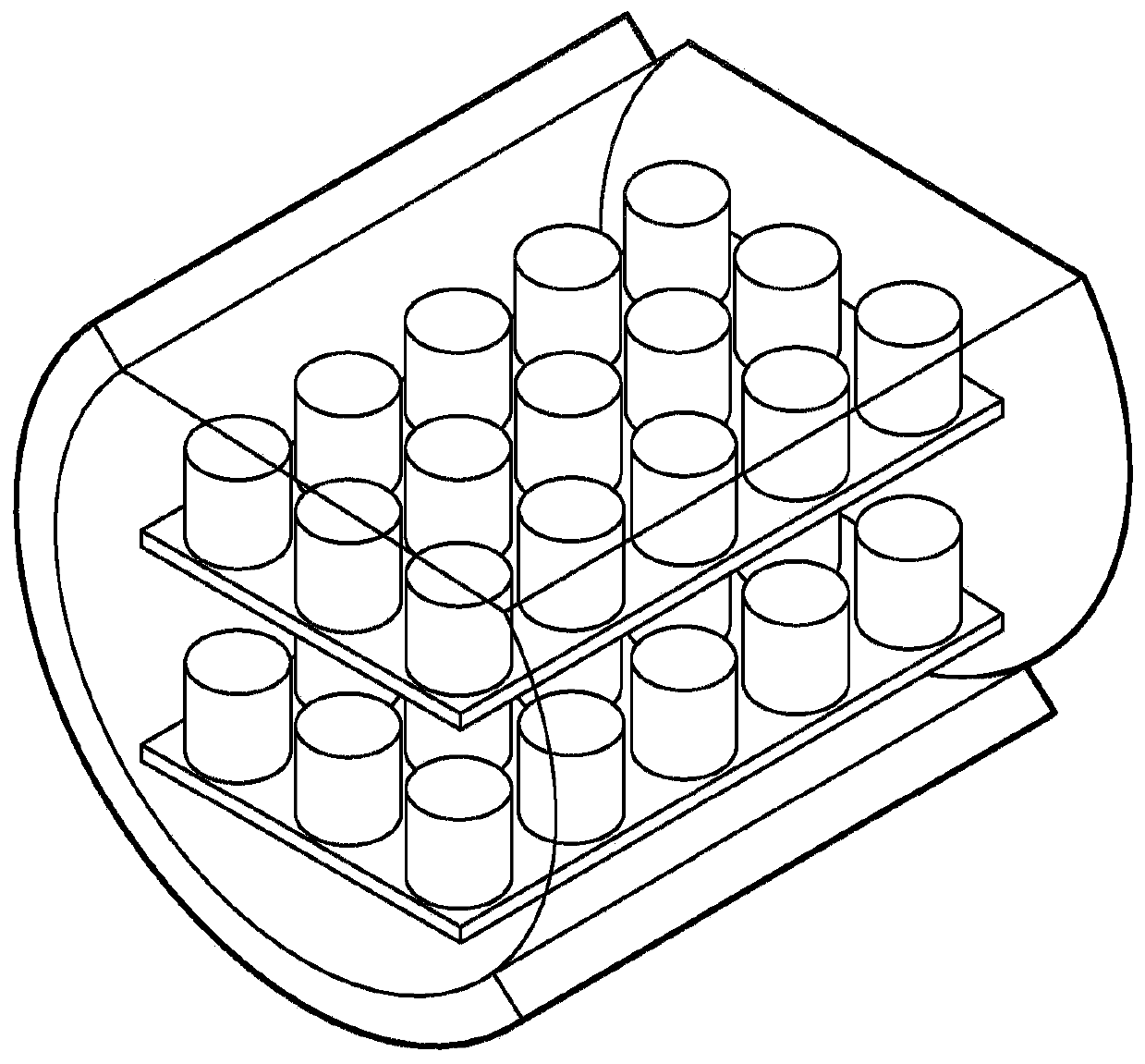

Image

Examples

Embodiment Construction

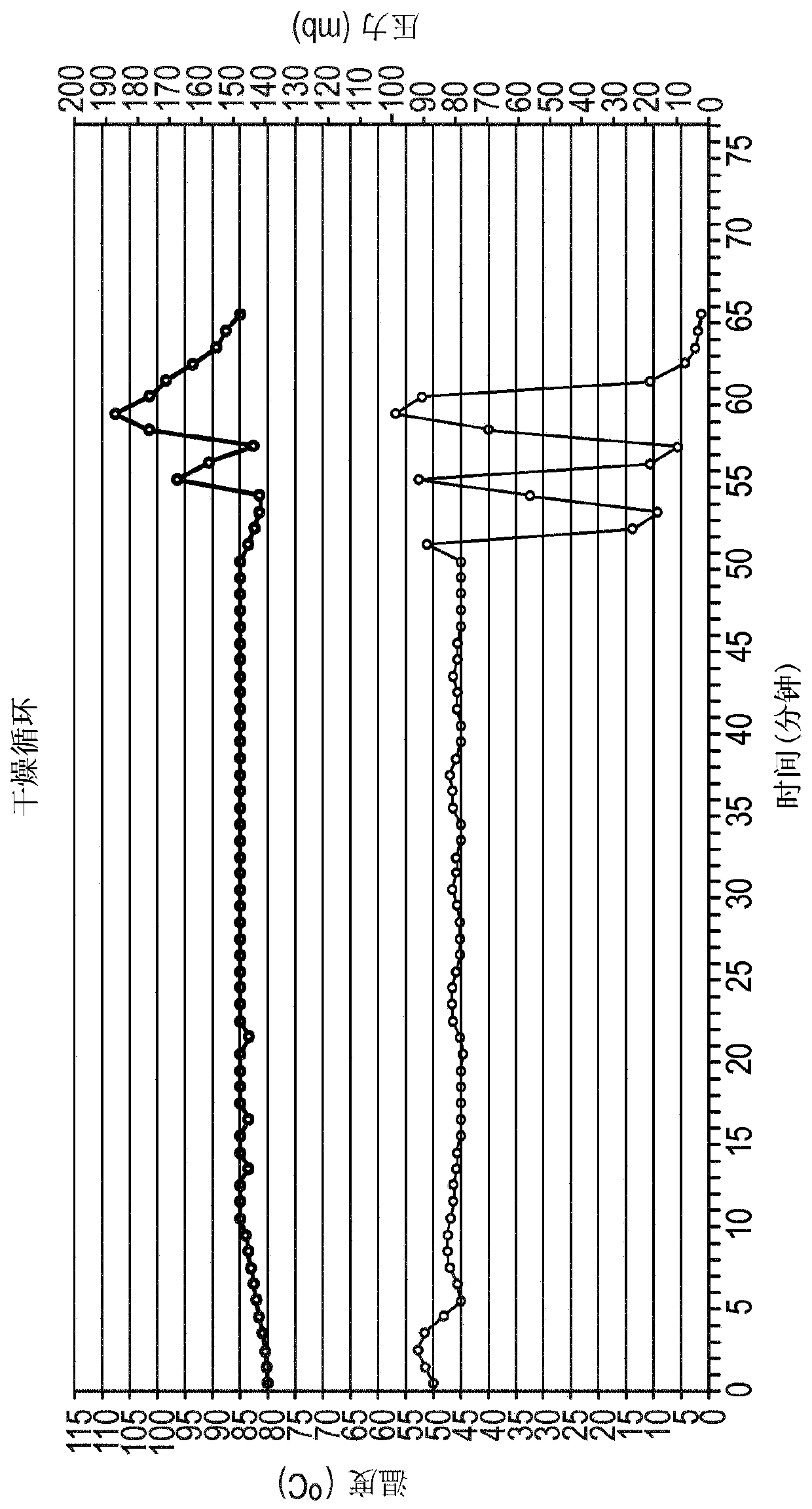

[0044] drying process

[0045]Provided herein are methods for drying (dewatering) ceramic bodies. In certain embodiments, the method removes at least about 70% by weight of water from the ceramic body. In certain embodiments, the method removes at least about 75% by weight, or at least about 80% by weight, or at least about 85% by weight, or at least about 90% by weight, or at least about 95% by weight, or At least about 96%, or at least about 97%, or at least about 98% by weight water. In certain embodiments, the method removes up to about 90% by weight, or up to about 95% by weight, or up to about 96% by weight, or up to about 97% by weight, or up to about 98% by weight, or up to about 99% or up to about 100% by weight water. For example, the method can remove from about 90% to about 99% by weight of water from the ceramic body.

[0046] In certain embodiments, the method can also remove organic compounds from the ceramic body. For example, the percentage of organic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com