Refiner with pumping function

A refiner and functional technology, which can be applied to household appliances, kitchen appliances, beverage preparation devices, etc., can solve problems such as affecting output and taste, increasing maintenance links, and inefficiency, and achieving the effect of saving work flow and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

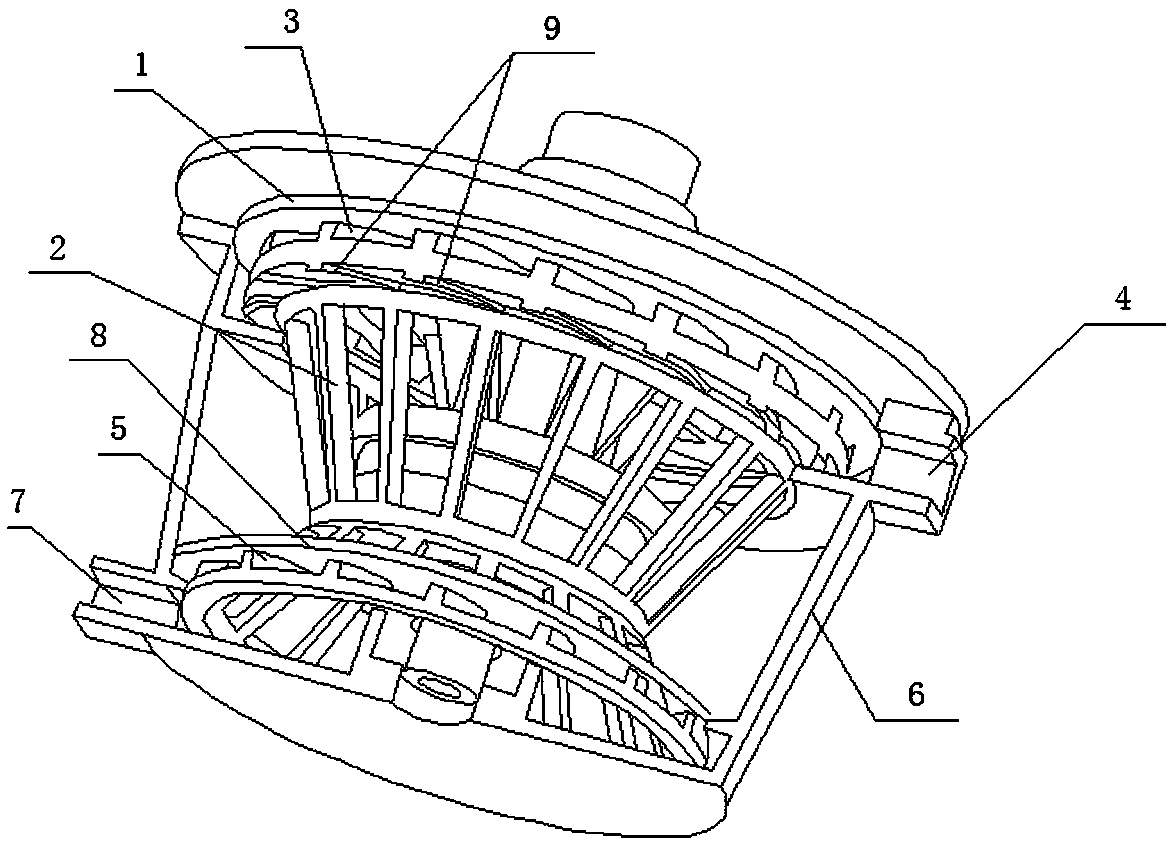

[0018] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be further described below in conjunction with the accompanying drawings:

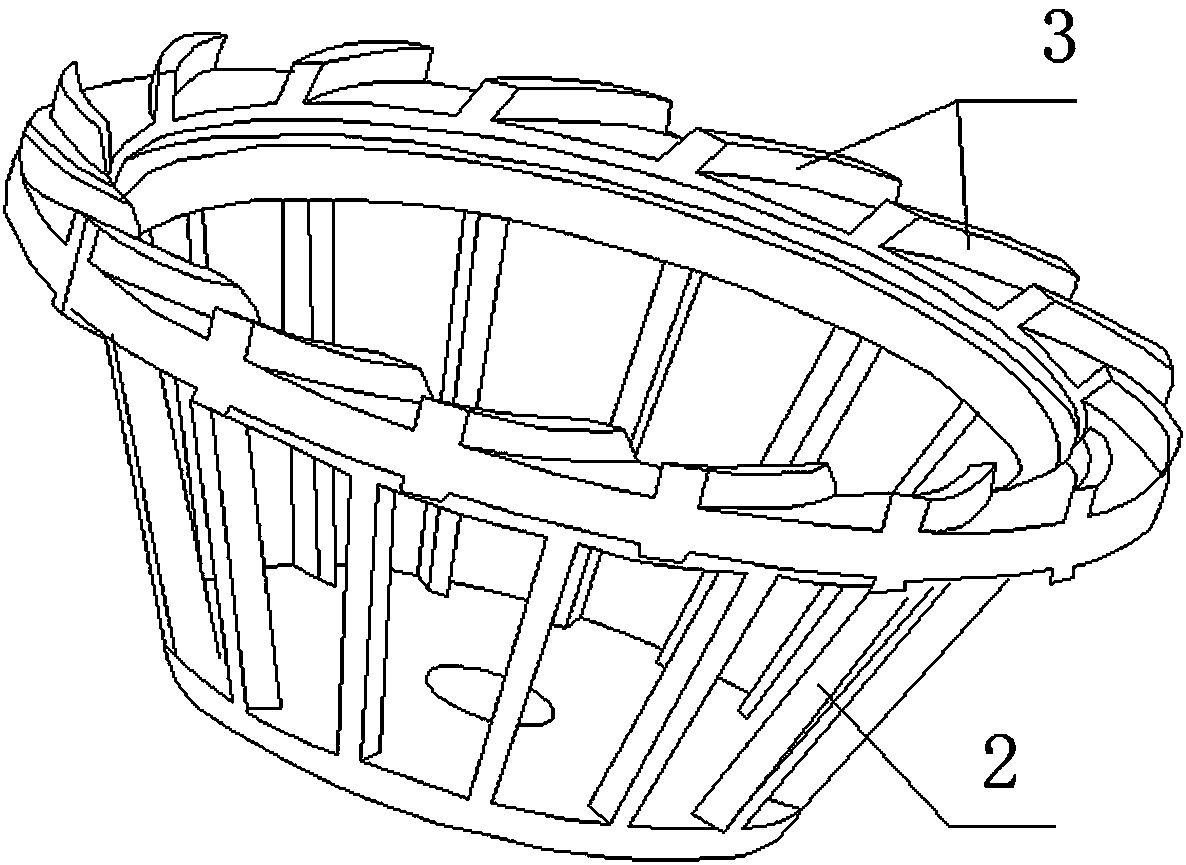

[0019] The invention relates to a refiner with pumping function, comprising an upper cover 1 and a cylinder body 6 with a built-in screening basket 2, the upper cover 1 is covered on the cylinder body to form a screening cavity, and the upper part of the cylinder body 6 is provided with a The upper discharge port 4 for pumping out the pulp residue is provided with a lower discharge port 7 for pumping out the soybean milk at the lower part of the cylinder 6, and a pump impeller blade is also arranged in the cylinder block 6. There are three ways to set the pump impeller blade. :

[0020] The first form is that the upper end of the screening basket 2 is provided with a blade 3 for pumping out the slurry as a pump impeller blade, and the blade 3 pumps the slurry out from the upper discharge port 4;

[0021] The second for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com