Mixing apparatus capable of realizing dynamic metering and proportioning

A mixing device and dynamic metering technology, which is applied to mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve the problems of unstable density and inaccurate weight ratio between base materials and auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

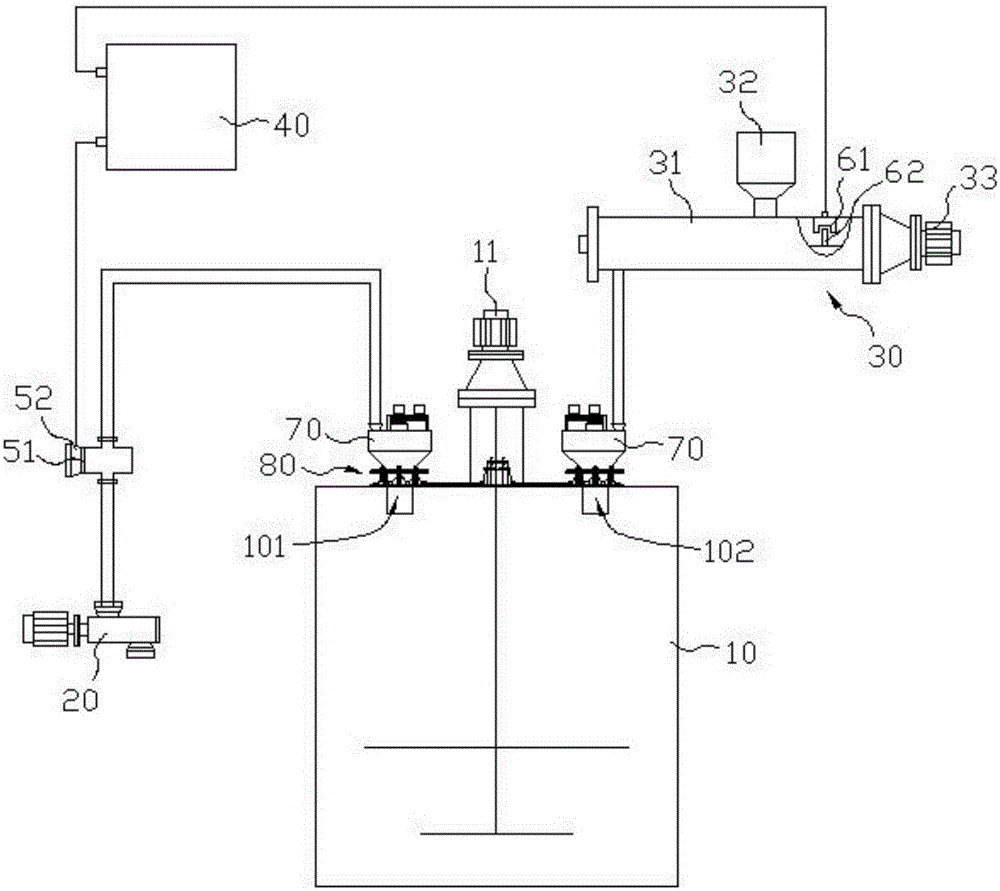

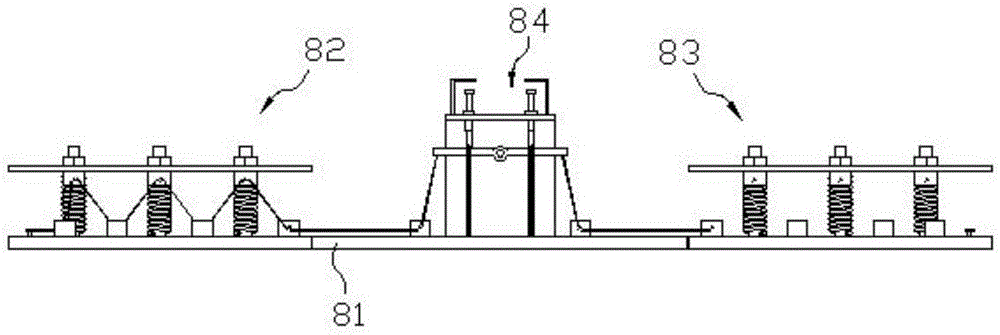

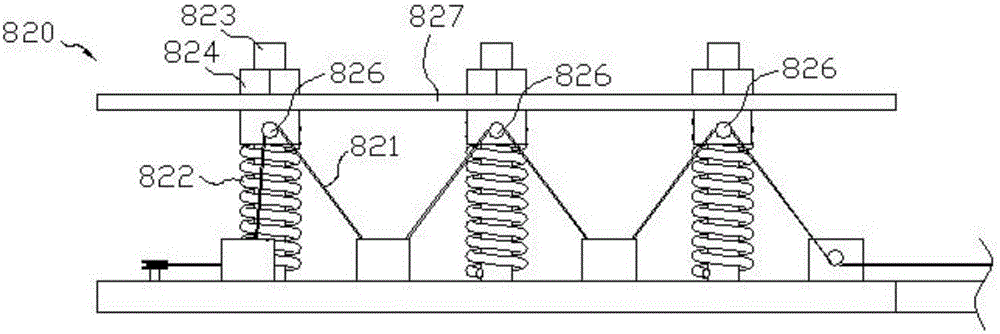

[0046] like figure 1 , a dynamic metering ratio mixing device, including a mixing tank 10, a speed-regulating delivery pump 20, a screw conveyor 30, a weighing metering ratio controller 40, a transition bin 70, and a weighing device 80.

[0047] like figure 1 , the top of the mixing tank 10 is provided with a stirring motor 11 , and the top of the mixing tank 10 is provided with a base material outlet 101 and an auxiliary material outlet 102 .

[0048] like figure 1 , the speed-regulating delivery pump 20 is connected with a delivery pipeline, one end of the delivery pipeline is connected with the speed-regulation delivery pump 20, the other end of the delivery pipeline is located above the base material outlet 101, and the delivery pipeline is provided with a flow meter 51 And base material pulse transmitter 52.

[0049] like figure 1 , the screw conveyor 30 includes a conveying cavity 31, a buffer hopper 32, and a speed-regulating motor 33. The conveying cavity 31 is hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com