Multi-synchronous bolt fastening device for connecting main shaft and gearbox of wind power generating set

A technology of a wind power generating set and a bolt fastening device, which is applied in the field of fastening bolts, can solve problems such as inconvenient installation and disassembly, high labor intensity, and long auxiliary time, so as to improve operating efficiency, reduce labor intensity, and shorten fastening time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific examples.

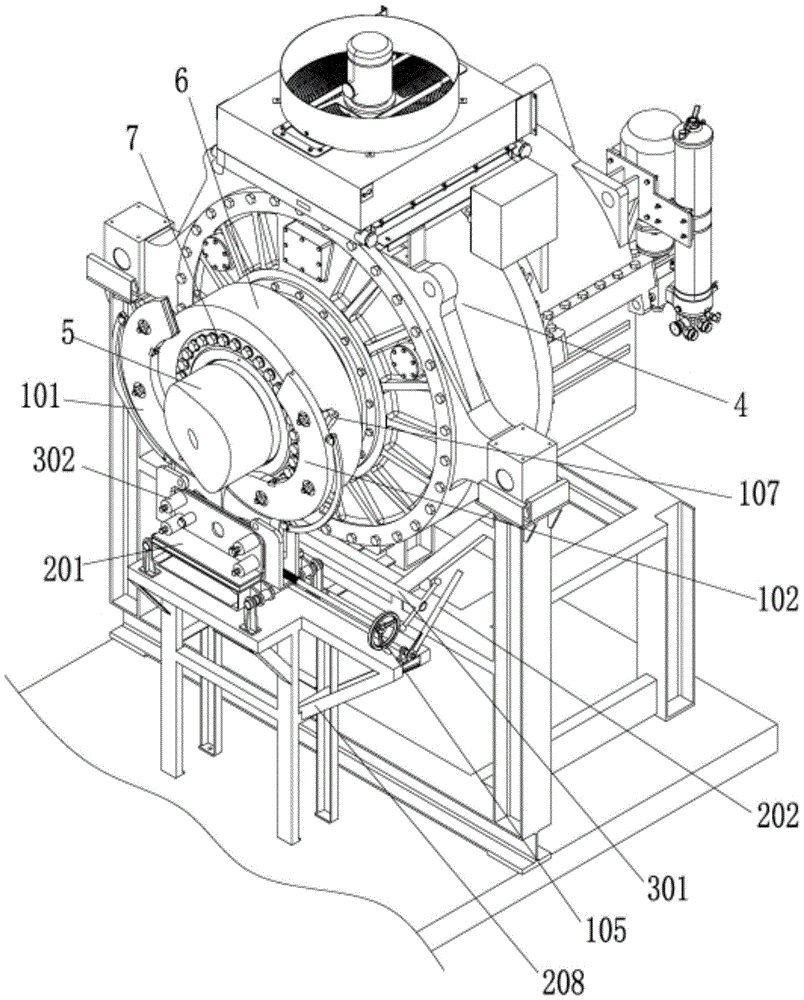

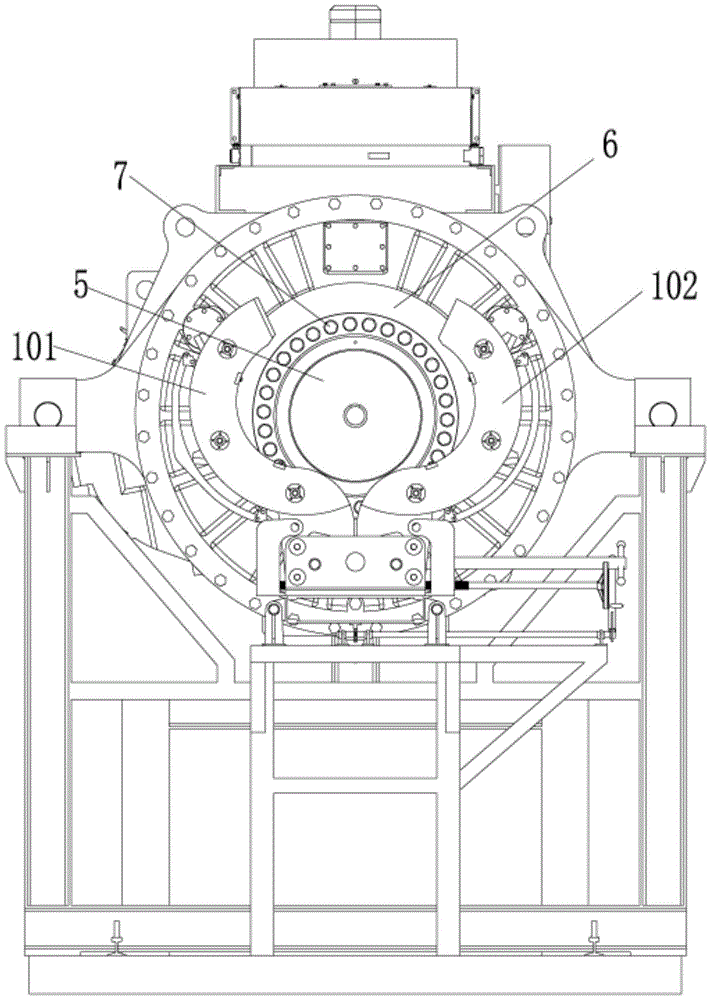

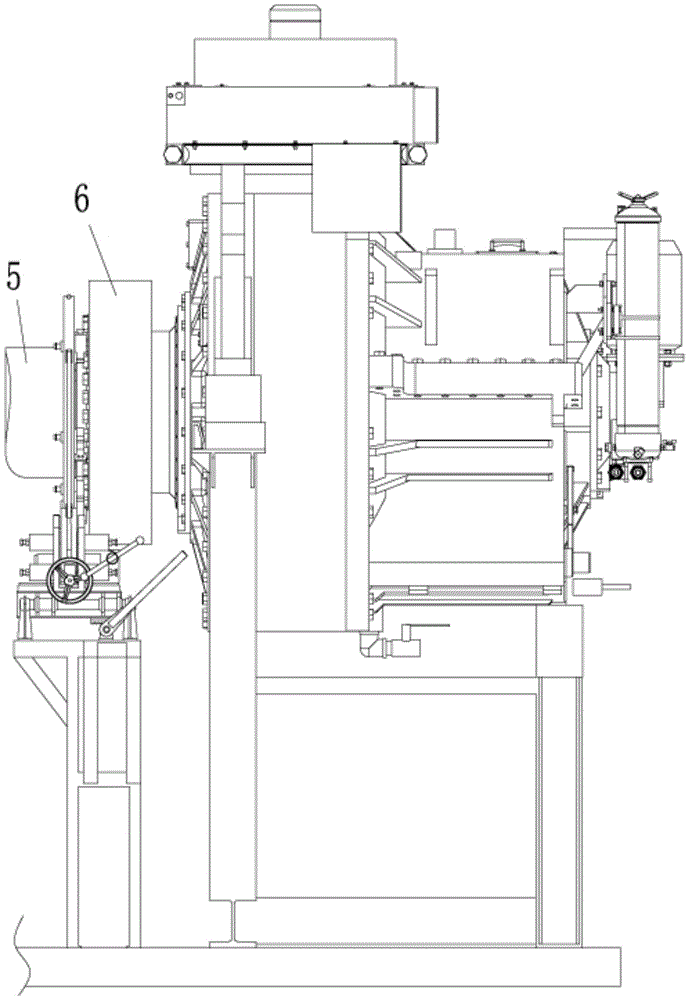

[0037] Such as Figure 1 to Figure 3 As shown, the multi-synchronous bolt fastening device for connecting the main shaft of the wind power generating set and the gearbox described in this embodiment is specifically a six-synchronous bolt fastening device, including a linkage opening and closing mechanism, a clamping mechanism and a wrench advance and retreat mechanism, Wherein, the linkage opening and closing mechanism and the clamping mechanism are respectively installed on the moving platform 201 of the wrench advancing and retreating mechanism, and can translate together with the moving platform 201 in the direction of the main shaft axis of the wind power generating set.

[0038] Such as Figure 4 to Figure 7 As shown, the linkage opening and closing mechanism includes two matching wrench mounting plates 101, 102, a rotating pin shaft 103, a screw mandrel 104, a hand wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com