Device for removing burrs on cut portion of window frame

A cutting part and deburring technology, which is applied in the field of deburring devices for the cutting part of window frames, can solve the problems of easy injury to installers, low burr removal efficiency, and damage to the health of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

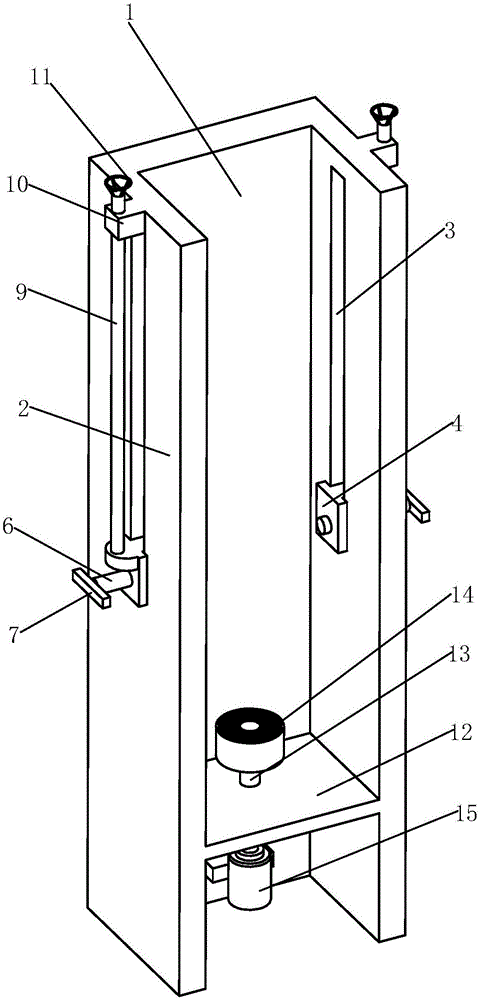

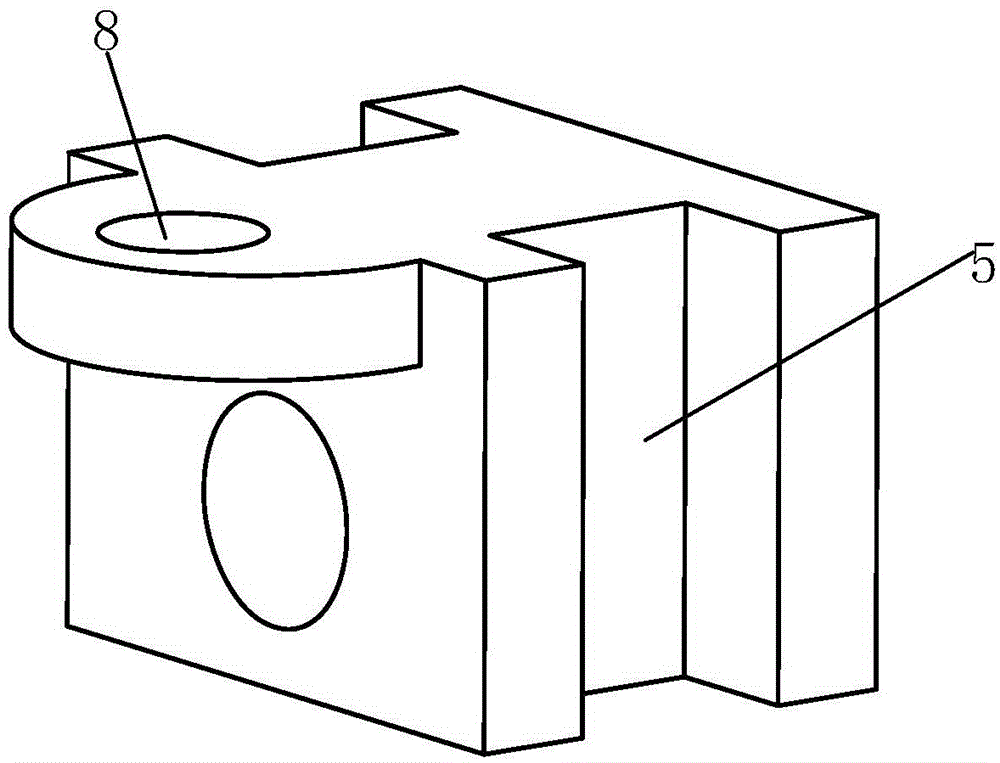

[0017] Such as Figure 1 to Figure 2 As shown, a window frame cutting part deburring device includes a riser 1, the front and rear sides of the riser 1 are provided with baffles 2 perpendicular to the riser 1, each of the baffles 2 is provided with a The strip-shaped hole 3 opened in the vertical direction is provided with a slider 4 in the strip-shaped hole 3, and the left and right sides of the slider 4 are provided with grooves 5 that cooperate with the strip-shaped hole 3. There are also threaded rods 6 in the longitudinal direction of the sliders 4 through threaded fit, and the inner ends of the threaded rods 6 pass through the sliders 4 and extend into the risers 1, and are equipped with pads made of rubber. The outer end of threaded rod 6 is all equipped with turning handle 7, and the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com