LED lamp cap cutting equipment

A technology of LED lamp holders and equipment, which is applied in metal processing and other directions, can solve the problems of inconvenient use of cutting equipment, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

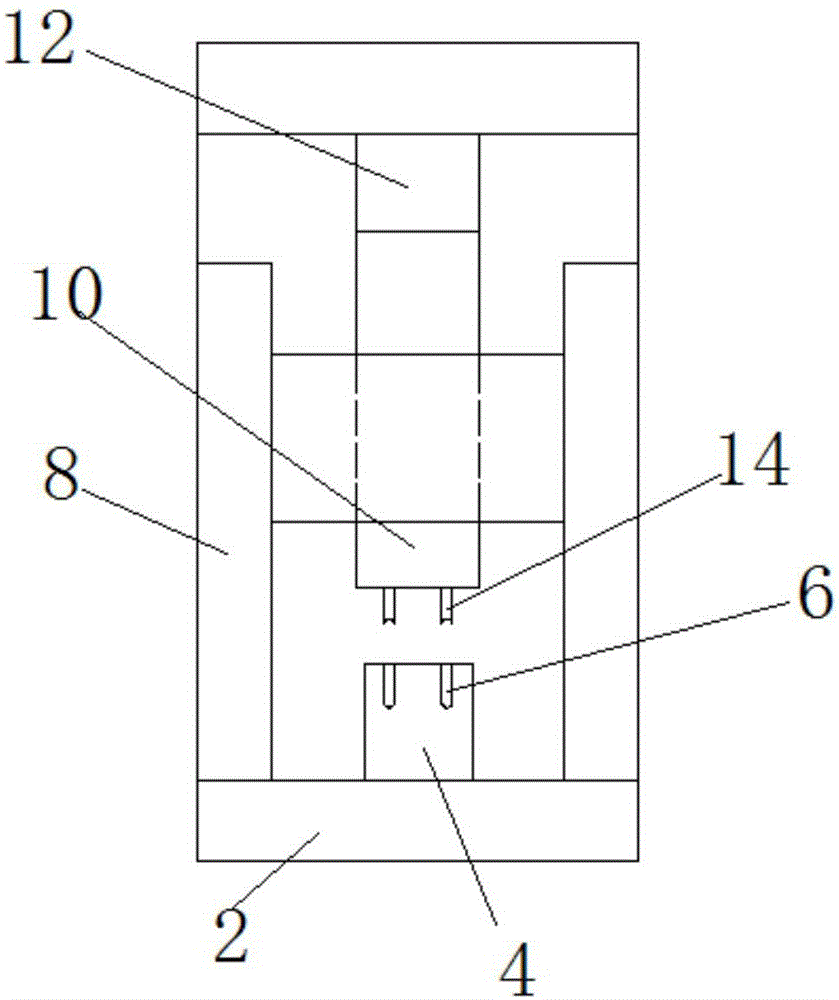

[0017] see figure 1 As shown, an LED lamp head cutting device of the present invention includes a base 2 arranged horizontally, on which a bottom mold 4 is arranged, and on the bottom mold 4 there are two grooves 6 arranged at intervals. A lower cutting edge is formed on the bottom wall of the groove 6; in addition, a stand 8 is also arranged on the base 2, and a patrix 10 is arranged on the stand 8, and the drive device 12 arranged on the top of the stand 8 is arranged on the patrix 10. Connected, the upper mold 10 can be driven by the driving device 12 to move toward the bottom mold 4 along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com