Dip-angle-adjustable cement mixer with accurate control of discharging

A cement mixer, precise control technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems that the materials are not easy to be discharged, the outlet cannot be closed in time, and the angle of the mixing tank cannot be adjusted, etc., to achieve Easy to clean, reduce cement waste, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

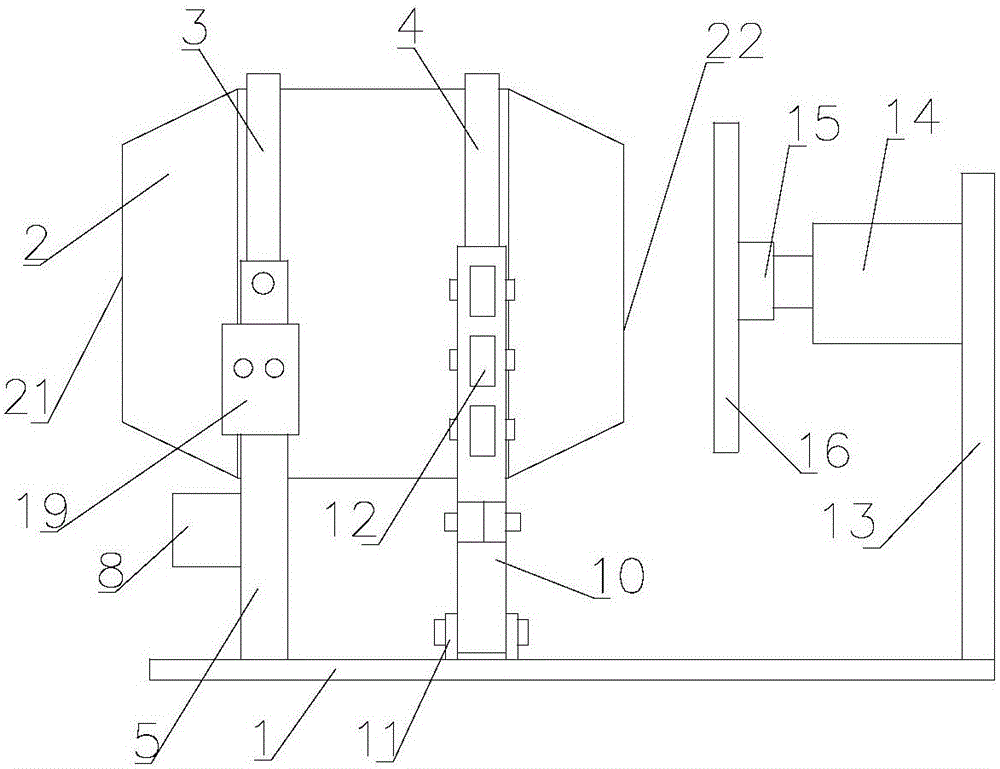

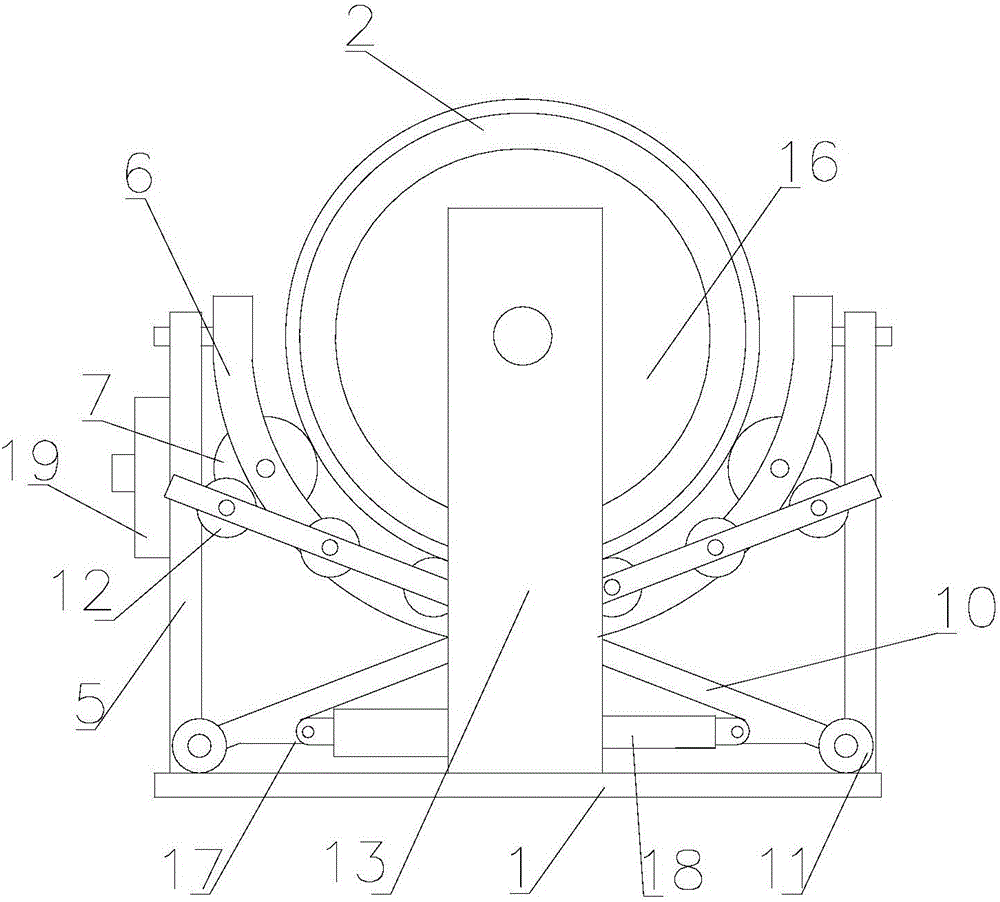

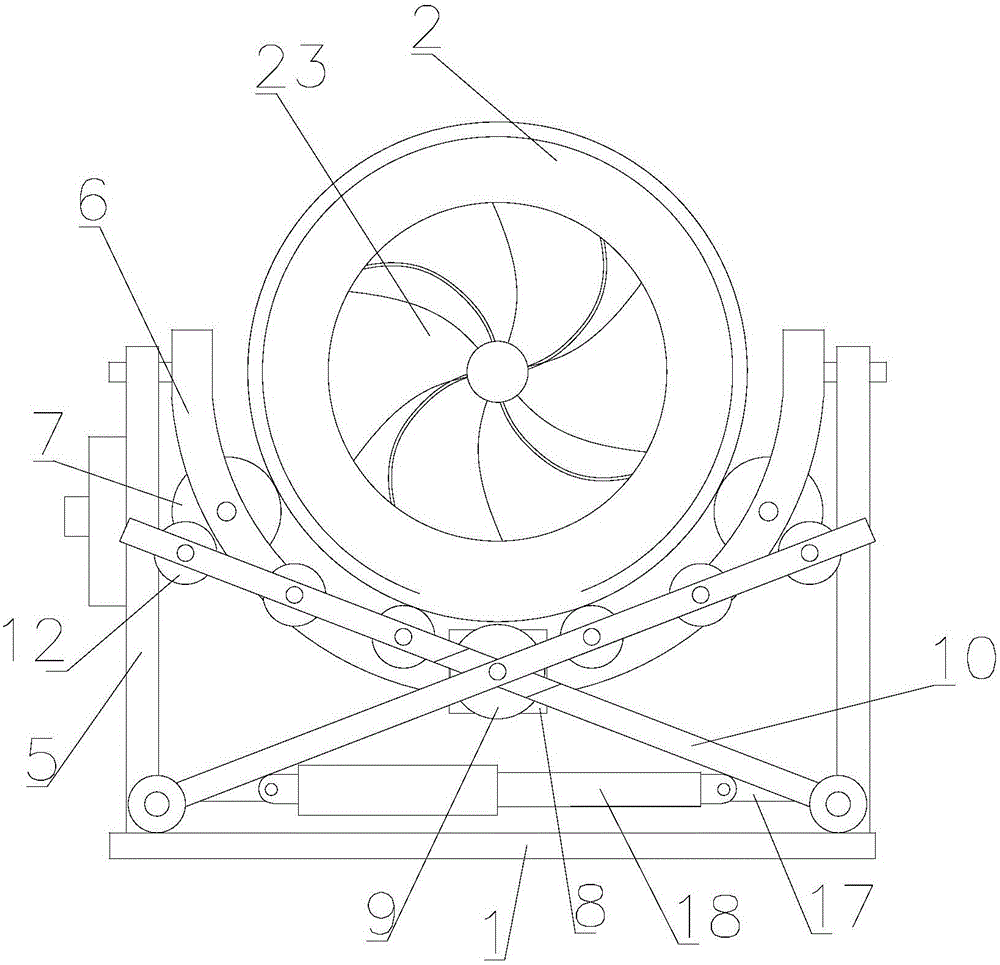

[0018] refer to figure 1 , figure 2 and image 3 , the present invention is an adjustable cement mixer with precise control of discharge inclination, including base 1, mixing bucket 2, front guide rail 3, rear guide rail 4, front bracket 5, front bracket 6, front supporting wheel 7, motor 8, power wheel 9. Rear support 10, inclination adjustment wheel 11, rear supporting wheel 12, end cover support 13, end cover hydraulic cylinder 14, end cover seat 15, end cover 16, hinged ear 17, inclination adjustment hydraulic cylinder 18 and electric control box 19 , the left side of the base 1 is fixedly equipped with a front bracket 5, the front bracket 5 is hingedly mounted with a front bracket 6, and the front bracket 6 is provided with two front supporting wheels 7, and the front supporting wheels 7 A motor 8 is arranged between them, and a power wheel 9 is installed on the motor 8. The power wheel 9 and the front supporting wheel 7 are respectively in contact with the mixing buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com