Hollow hub transmission mechanism and balance vehicle

A technology of transmission mechanism and hollow hub, which is applied in the field of balance car products and hollow hub transmission mechanism, can solve the problems of poor wheel stability and other problems, and achieve the effects of improving driving stability, easy control, and strengthening structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

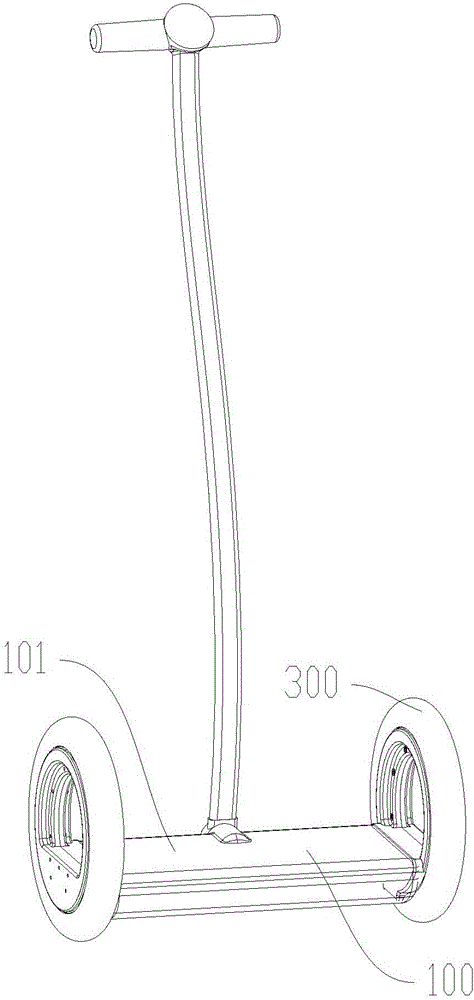

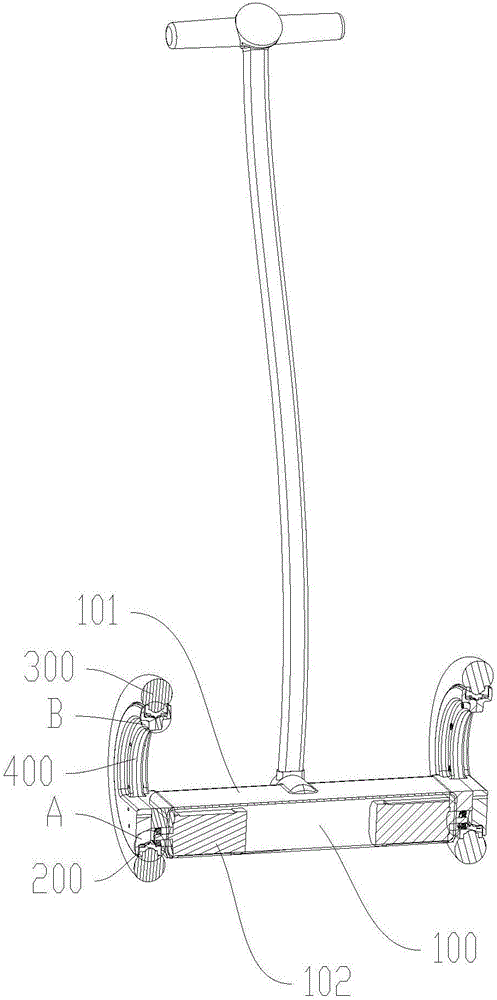

[0029] A hollow hub transmission mechanism, such as Figure 1-4 As shown, it is usually used for a balance car with a long handle, or a vehicle with a similar structure. Since the wheels of this type of vehicle are large and have a long handle, the wheels are prone to deflection and affect the transmission. efficiency. This embodiment describes a hollow hub transmission mechanism, which includes a vehicle body 100 with an upper end surface 101 as a pedal, an annular hub 200 arranged at both ends of the vehicle body 100 and connected with a drive assembly 102 arranged inside the vehicle body 100, and arranged on the vehicle body 100. The tire 300 on the outer side of the annular hub 200 and the bracket assembly disposed on the inner side of the annular hub 200 . The upper end surface is composed of the upper cover of the vehicle body 100 , which forms a cavity with the lower shell of the vehicle body 100 for accommodating the driving assembly 102 . The drive assembly 102 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com