Four-vortex kinetic energy pulping equipment with oblique inlet flow as power

An airflow and power technology, applied in the field of four-scroll kinetic energy pulping equipment powered by oblique airflow, can solve the problems of high energy consumption and low efficiency, and achieve the elimination of airflow kinetic energy loss, reduce kinetic energy loss, and improve The effect of pulping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

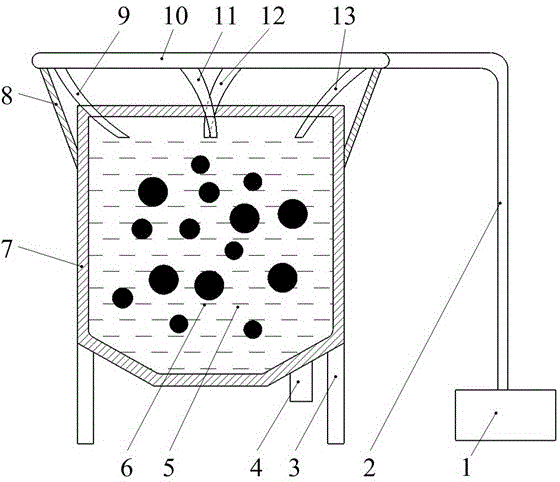

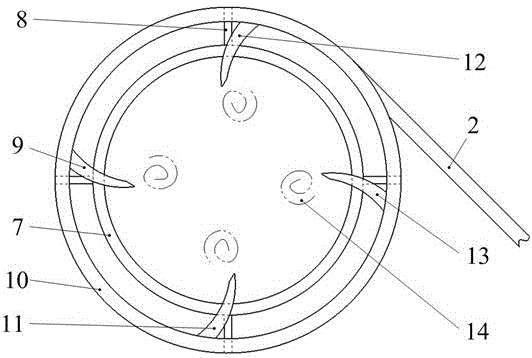

[0015] Such as figure 1 As shown, a four-vortex kinetic energy pulping equipment powered by oblique airflow of the present invention mainly includes an air intake device, a vortex airflow generating device and a slurry generating device, an air inlet device and a vortex airflow generating device Connected, the vortex air flow generation device is installed above the slurry generation device through the circular intake pipe pillar 8. The air intake device mainly includes an air compressor 1 and a main air intake pipe 2, and the main air intake pipe 2 is tangentially connected with the circular air intake pipe 10 in the vortex air flow generating device.

[0016] The slurry generating device mainly includes a pulper barrel 7 and a discharge port 4. The pulper barrel 7 is open without a cover. The pulper barrel 7 is equipped with water 5 and scrap 6. 4 pillars 3 evenly distributed in the circumferential direction, and the outlet 4 is installed on the lower bottom surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com