Fully automatic hydraulic oil pumping unit with double cylinders connected in parallel

A fully automatic pumping unit technology, applied in the direction of machines/engines, liquid displacement machines, mechanical equipment, etc., can solve the problems of increasing stroke times, fast speed, reducing the service life of oil cylinders, etc., and achieve the reduction of motor power The effect of small size, improved service life, and elimination of kinetic energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

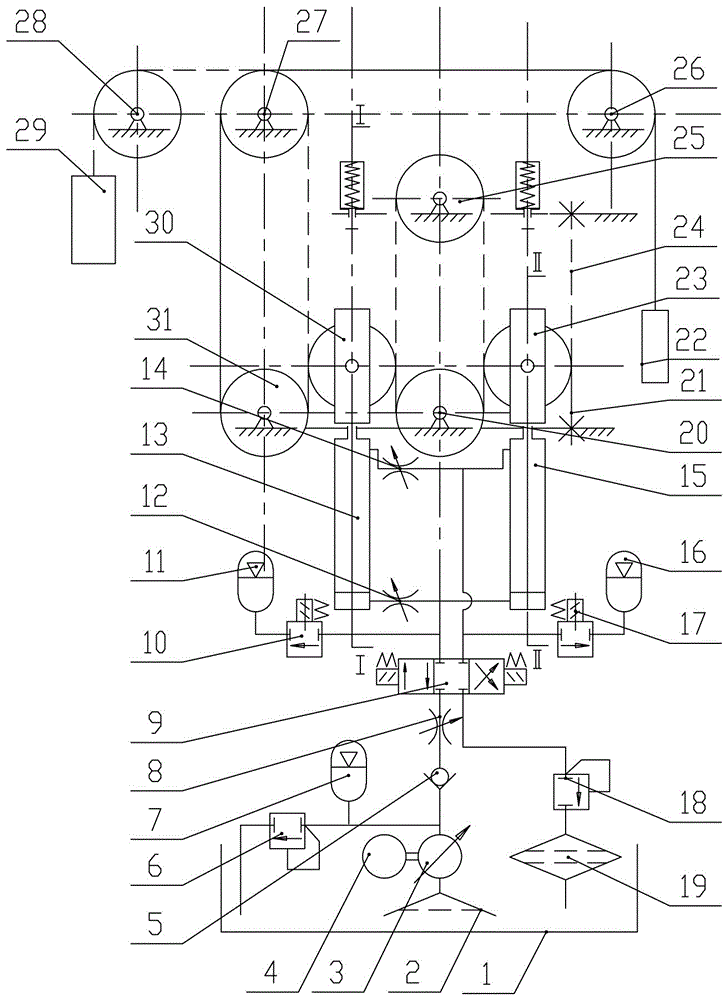

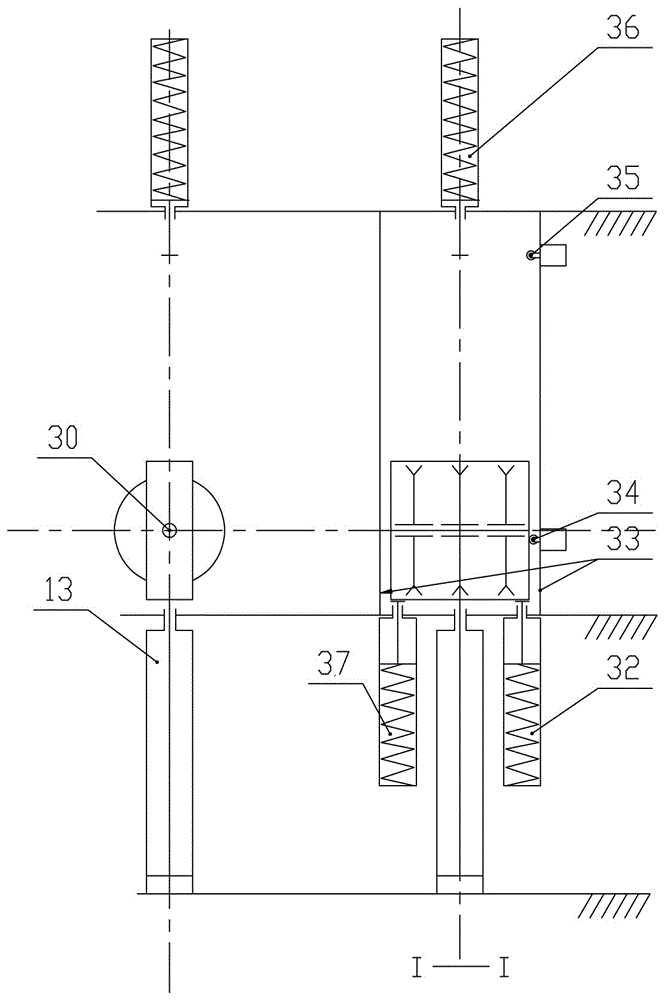

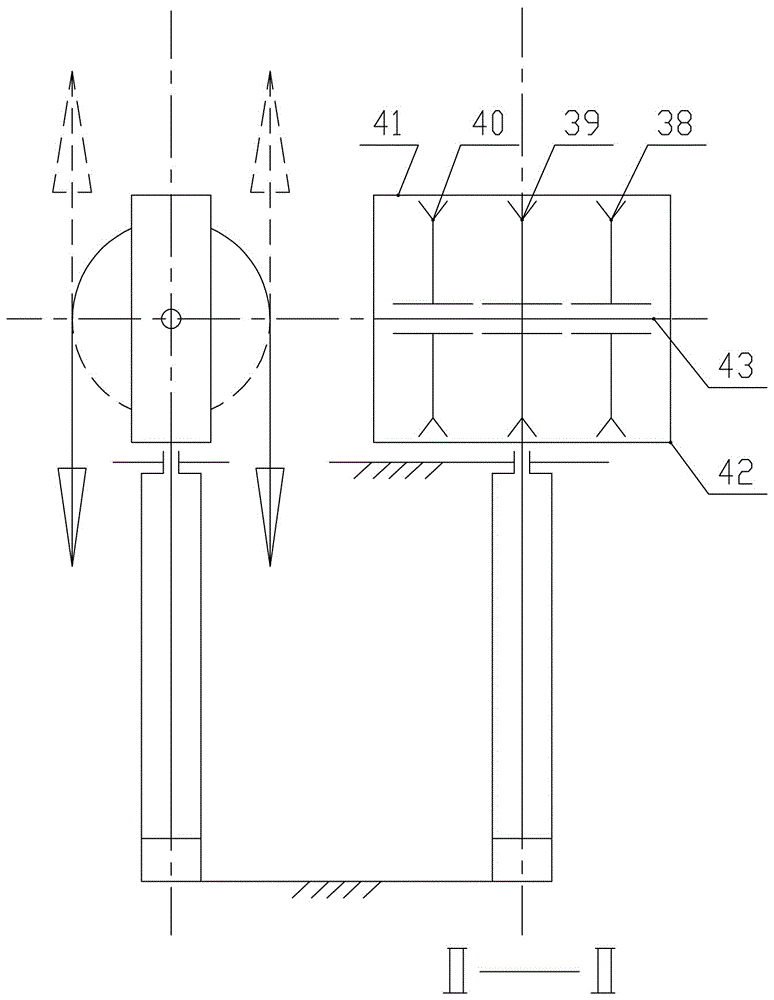

[0026] Such as figure 1 , 2 As shown in 3, the dual-cylinder parallel fully automatic hydraulic pumping unit of the present invention includes a vertical derrick, a hydraulic transmission system, a mechanical transmission mechanism composed of a well-mounted traction pulley block and a counterweight traction pulley block, a counterweight device, a well-hanging device, Kinetic energy recovery and utilization device and automatic control system,

[0027] The vertical derrick is mainly composed of a basic frame, a wheel bridge, an upper plate, an upper partition, a lower partition, a bottom plate and two sets of vertical slide rails 33. The vertical derrick is surrounded by a thin steel plate welded and closed, and the upper plate, The upper partition, the lower partition and the bottom plate constitute three enclosed spaces on three layers. Almost all the parts and components of the automatic hydraulic pumping unit are in the three enclosed spaces to prevent wind, rain, ice, frost a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com