A road body construction method with cold protection function

A construction method and road body technology, which is applied to roads, roads, pavement details, etc., can solve problems such as unsatisfactory snow melting and deicing effects, low intelligence, and damage to road surface performance, so as to reduce the risk of misalignment and improve safety. Sexuality, prolonging the effect of making life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A road body construction method with cold protection function, comprising the following steps:

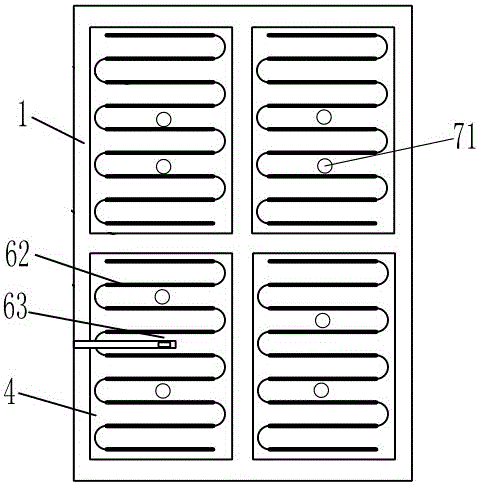

[0052] 1. Conduct a power-on test before the heating cables to be laid enter the site to check whether each heating cable can work normally, and level and clean the pavement base 1;

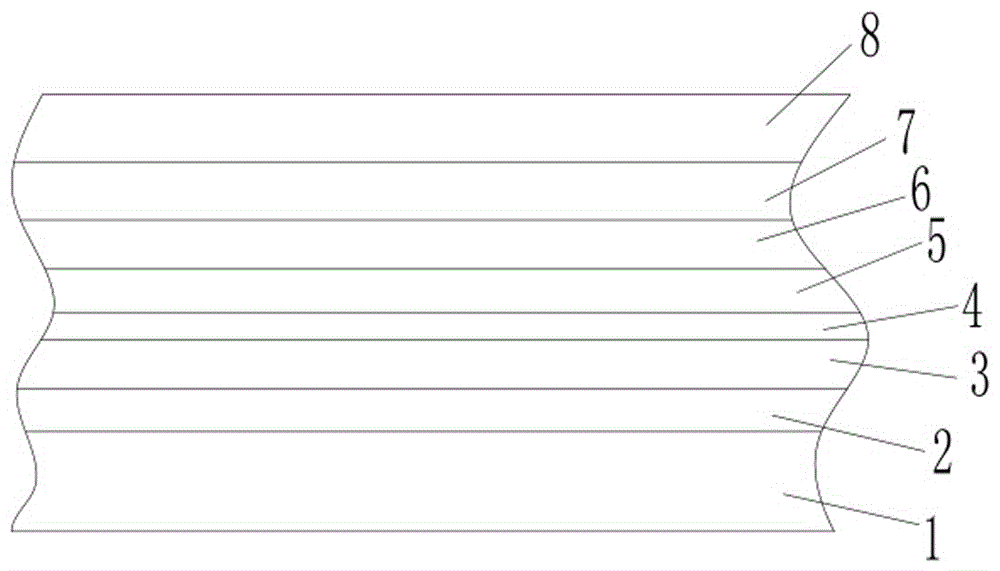

[0053] 2. Laying the moisture-proof layer 2, the moisture-proof layer can choose PVC moisture-proof film;

[0054] 3. Lay the heat insulating layer 3 and the reflective layer 4, the reflective layer is an aluminum foil layer glued on the heat insulating layer;

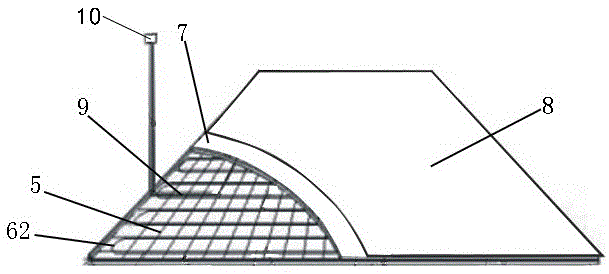

[0055] 4. Laying the heat dissipation layer 5. In this application, metal mesh is used as the heat dissipation layer. Adjacent metal mesh layers are crimped or connected by conductors. The conductors can be copper wires, and the metal mesh is grounded. The metal mesh includes primary heat dissipation strip sections 51 with dense mesh wires and secondary heat dissipation strip sections 52 with sparse mesh wires arranged at intervals in se...

Embodiment 2

[0064] The difference from the above embodiment is that the thickness of the pavement cushion layer 7 is 5 cm, and the distance from the outer side of the heating cable layer close to the side of the pavement base layer to the side of the pavement base layer is 12 cm.

Embodiment 3

[0066] The difference from the above embodiment is that the thickness of the pavement cushion layer 7 is 3 cm, and the distance from the outer side of the heating cable layer close to the side of the pavement base layer to the side of the pavement base layer is 10 cm.

[0067] This application completely solves the problem of icing on the road surface, and heats the road surface before the road surface is icy, so as to ensure that the road surface will not freeze and at the same time improve the performance of the road body, prevent the road surface from freezing to affect the performance of the road body, and shorten the service life of the road body. At the same time, carbon fiber cables are used, which have high safety, and the heating temperature will not be too high. Excessive temperature will also affect the performance of the road body. Through the design of the road body in this application, the service life of the road body can be extended and the road surface can be im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com