Pile leg pitch of self-elevating drilling platform

A drilling platform and self-elevating technology, applied in the field of pile leg pitch, can solve the problems of small wind receiving area, small number of rods, small welding workload, etc., to achieve higher operating water depth, fewer pipes, and save material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

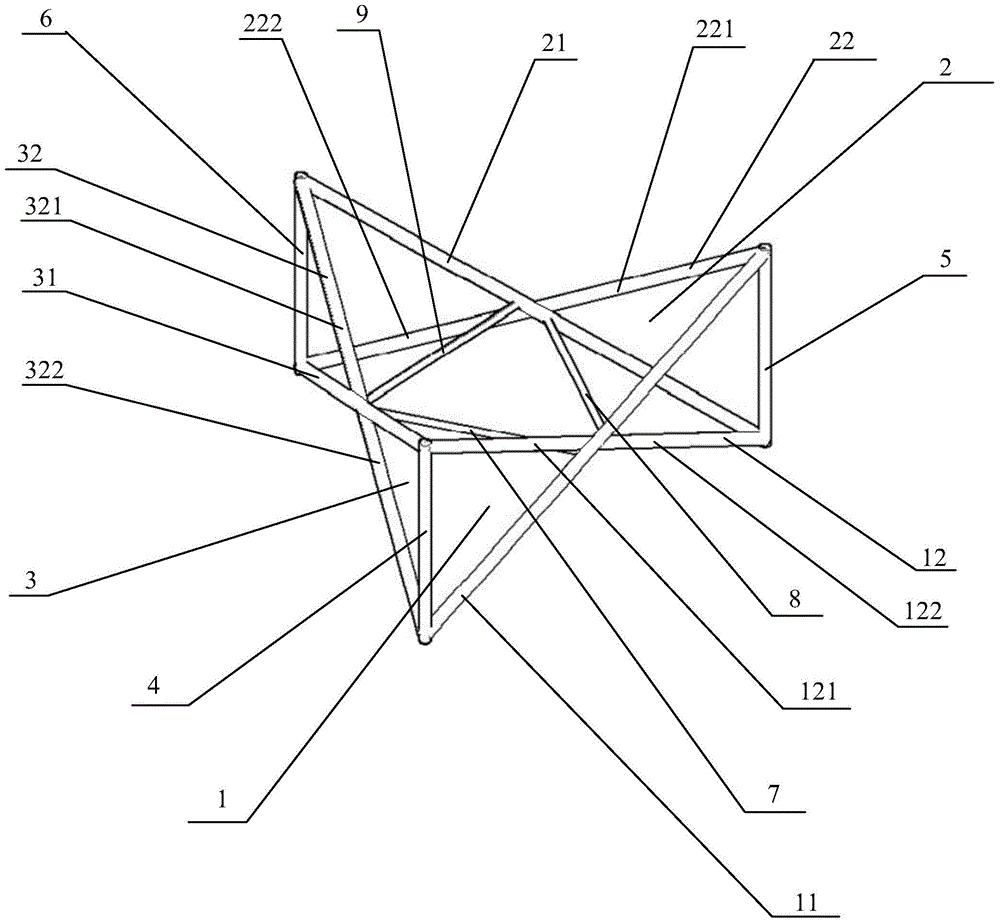

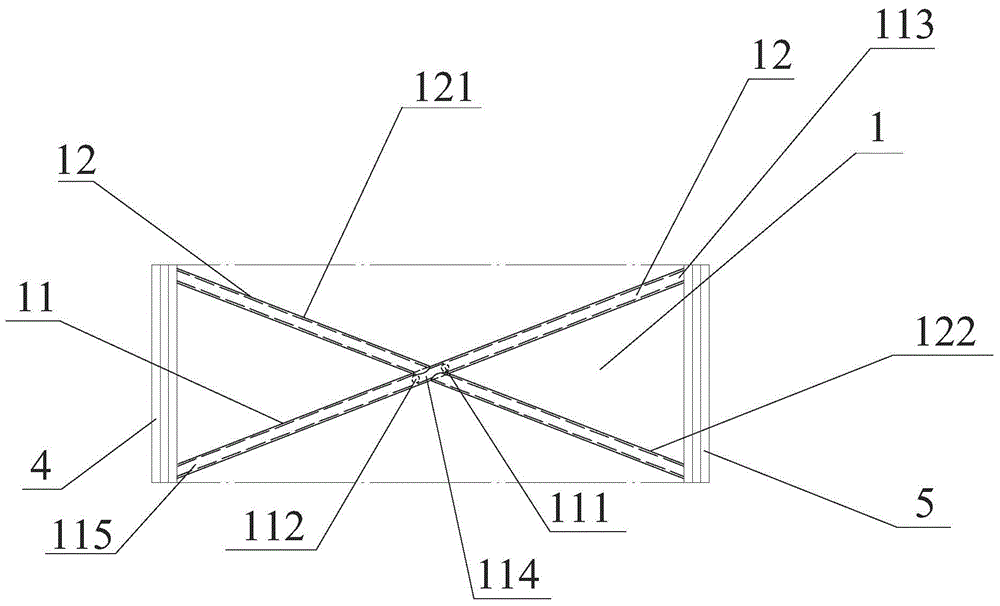

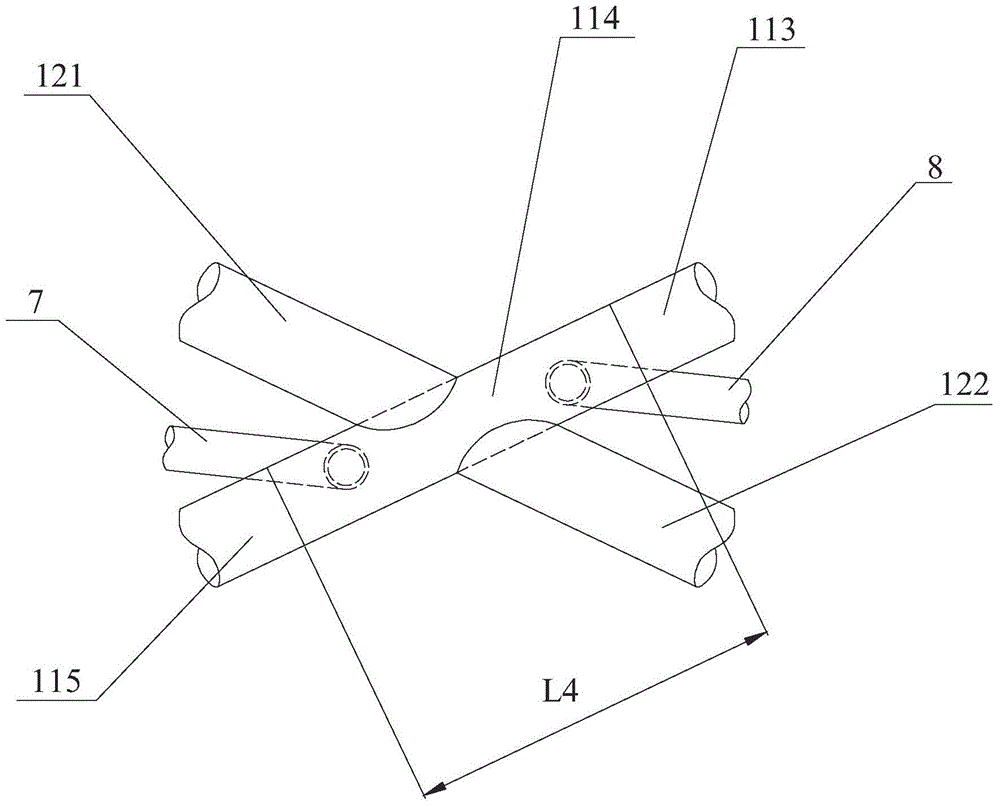

[0025] refer to figure 1 , figure 2 and Figure 4 , the figure shows a leg pitch of a jack-up drilling platform. The leg pitch is a truss structure surrounded by three rectangular sides and the outer edge of the cross section is an equilateral triangle. The leg pitch The three rectangular sides are the first rectangular side 1 , the second rectangular side 2 and the third rectangular side 3 in sequence.

[0026] The leg pitch includes three outrigger chords, respectively the first outrigger chord 4, the second outrigger chord 5, and the third outrigger chord 6, and the three outrigger chords are respectively set at the vertices of an equilateral triangle place. This triangular truss structure is more stable than the quadrilateral leg structure in the prior art, and the number of pipes used is also reduced. The leg pitch of the existing jack-up drilling platform g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com