Typhoon defense operation control method for wind driven generator group, device and the group using the device

A technology of operation control and wind power generating set, which is applied in the direction of wind power motor combination, wind power engine control, wind power generation, etc. To achieve the effect of being easy to promote, preventing damage, and reducing the impact of typhoons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

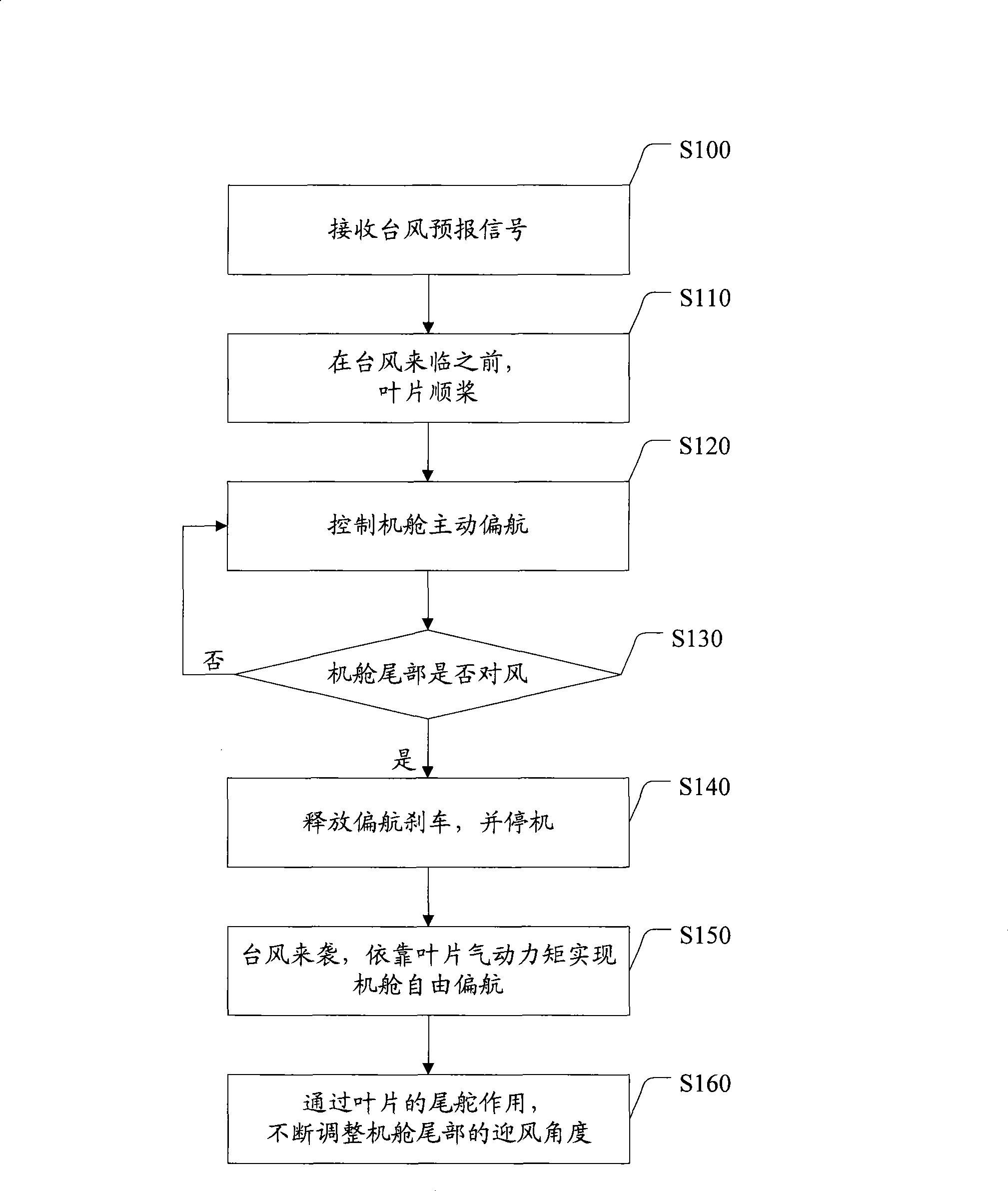

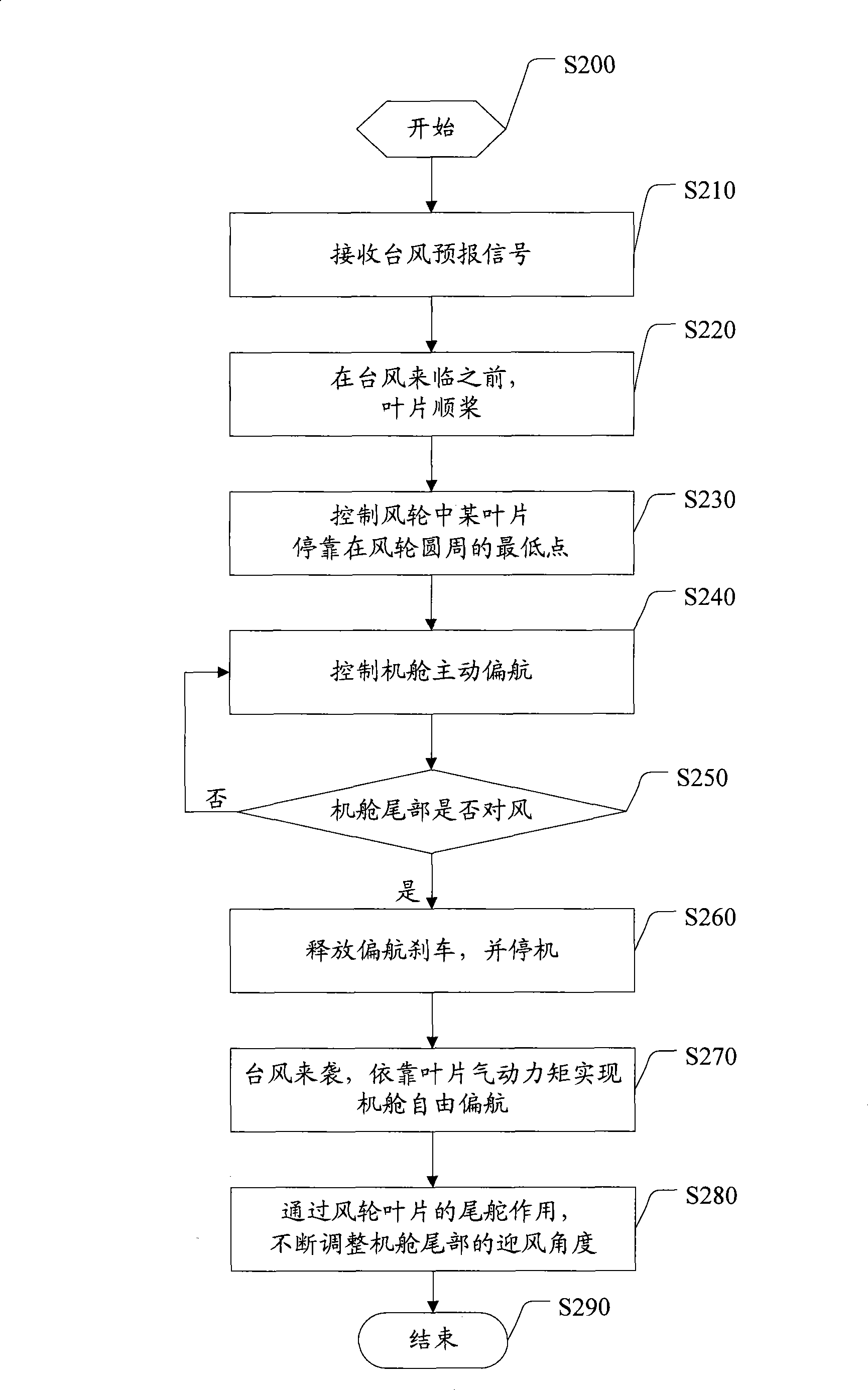

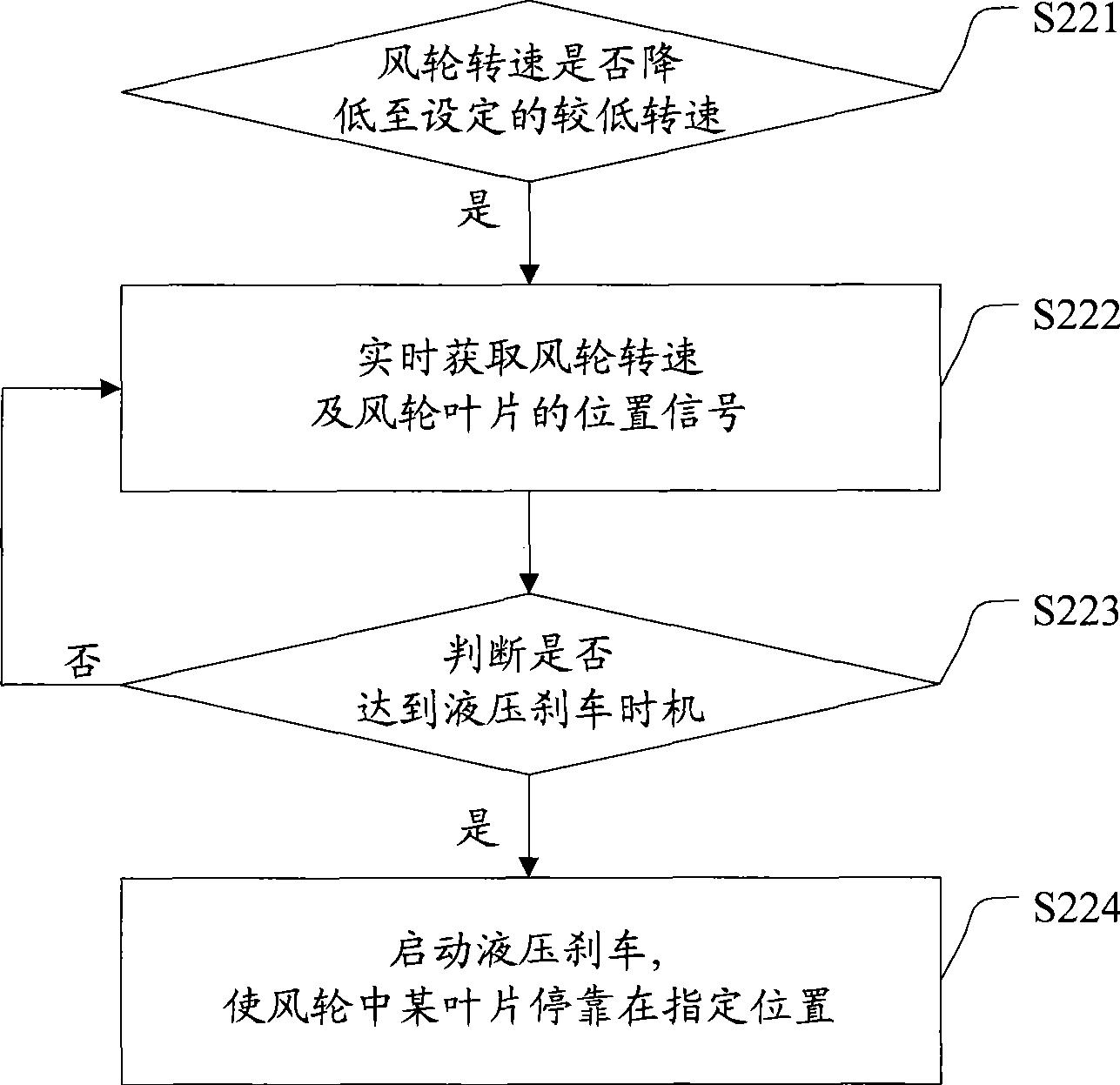

[0056] The basic idea of the present invention is: when the typhoon is coming, the blades are feathered, the active yaw of the nacelle is controlled, the head of the nacelle is rotated to the downwind direction, the yaw brake is released and the machine is stopped; Free yaw ensures that the tail of the cabin is always facing the wind, and at the same time, through the action of the tail rudder of the blades, the windward angle of the tail of the cabin is constantly adjusted.

[0057] The following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0058] Please refer to figure 1 , which is a flow chart of the first embodiment of the typhoon-proof operation control method for wind power generating sets of the present invention. This embodiment comprises the following steps:

[0059] S100. Receive a typhoon forecast signal.

[0060] When receiving the typhoon forecast, start the next step of the control program.

[0061] S110, before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com