A fast-installation pipeline fixing system

A pipeline and quick-installation technology, which is applied in the direction of pipeline supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of torsional stress, poor safety performance of pipe fixing, poor safety and reliability, etc., so as to be suitable for adjustment and Installation, avoiding potential safety hazards, and strong adjustment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

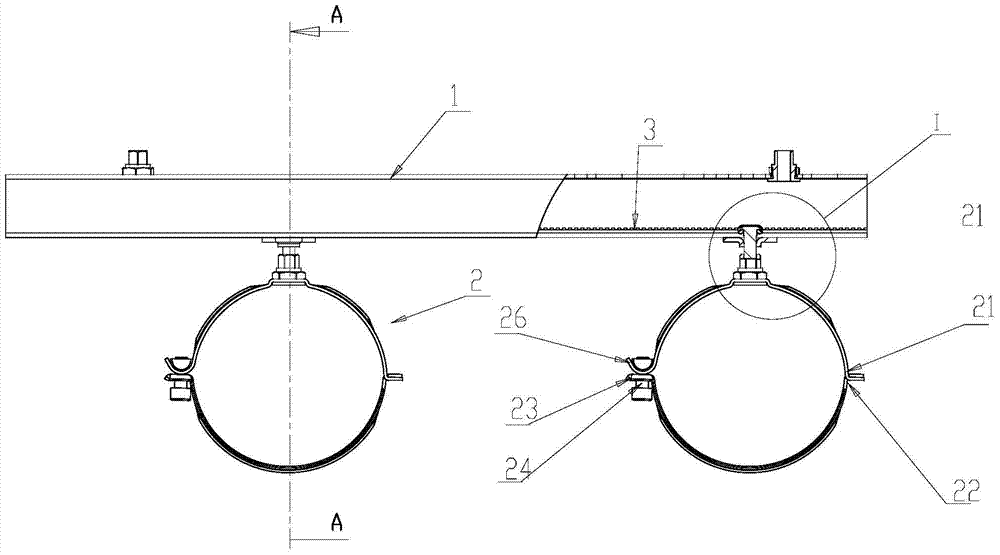

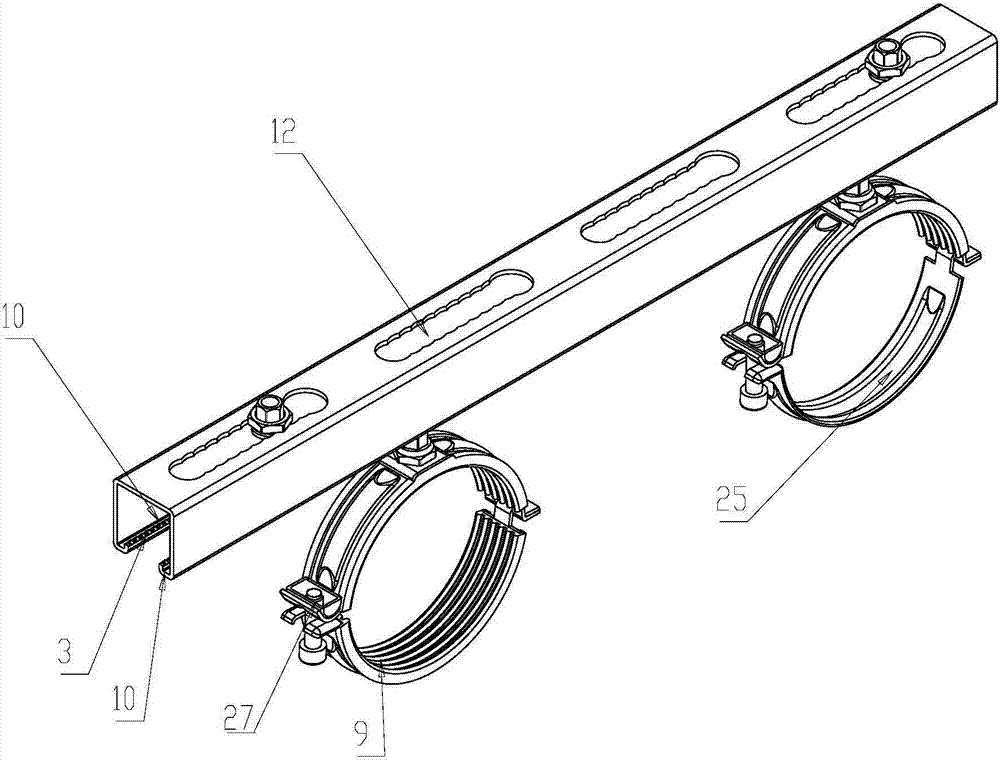

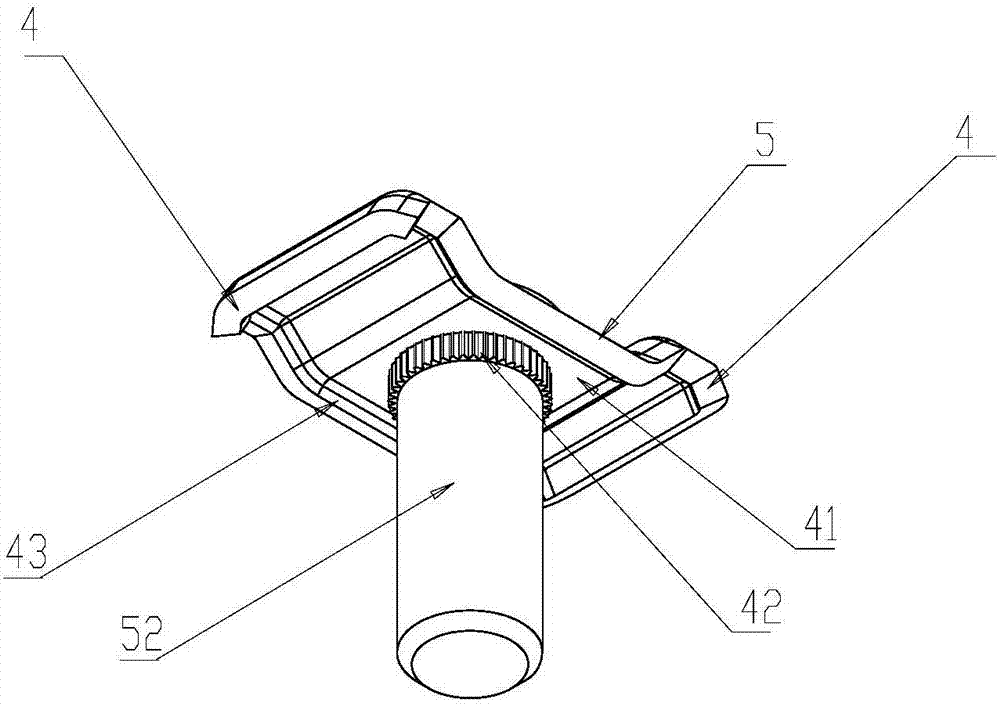

[0040] Refer to attached picture. A fast-installed pipeline fixing system provided by the present invention includes a living joint pipe 2 with a movable connection part 51, a sinking lock hanger 5 with a fixed rod 52, and a sunken lock with a fixed rod 52. The lock hanger 5 is fastened to the fastener 8 on the part 1 with the hook groove; the sunken lock hanger with a fixed rod is composed of the lock hooks 4 at both ends and the sinking connecting bridge 41 in the middle, the fixed The rod 52 is fixedly connected with the sinking connecting bridge 41 as a whole, and the locking hook 4 can cooperate with the locking position 3 on the part 1 with the hook groove 10 to prevent the sinking lock hanger 5 with the fixed rod from rotating; The movable connecting part 51 is movably connected with the connecting end of the fixed rod 52 to adjust the position of the pipe collar.

[0041]In the present invention, the sunken lock and hanger plays the role of positioning and support. It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com