Sealing joint used for connecting bamboo-like prestress flat plastic pipes and provided with exhaust pipe

A technology for sealing joints and flat mouth pipes, which is applied in the directions of pipes/pipe joints/fittings, pipeline connection arrangement, passing elements, etc., which can solve the problems affecting the grouting compactness and fullness of vacuum prestressed holes, complicated connection methods and poor sealing effect. and other problems, to achieve the effect of simple structure, reliable performance and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

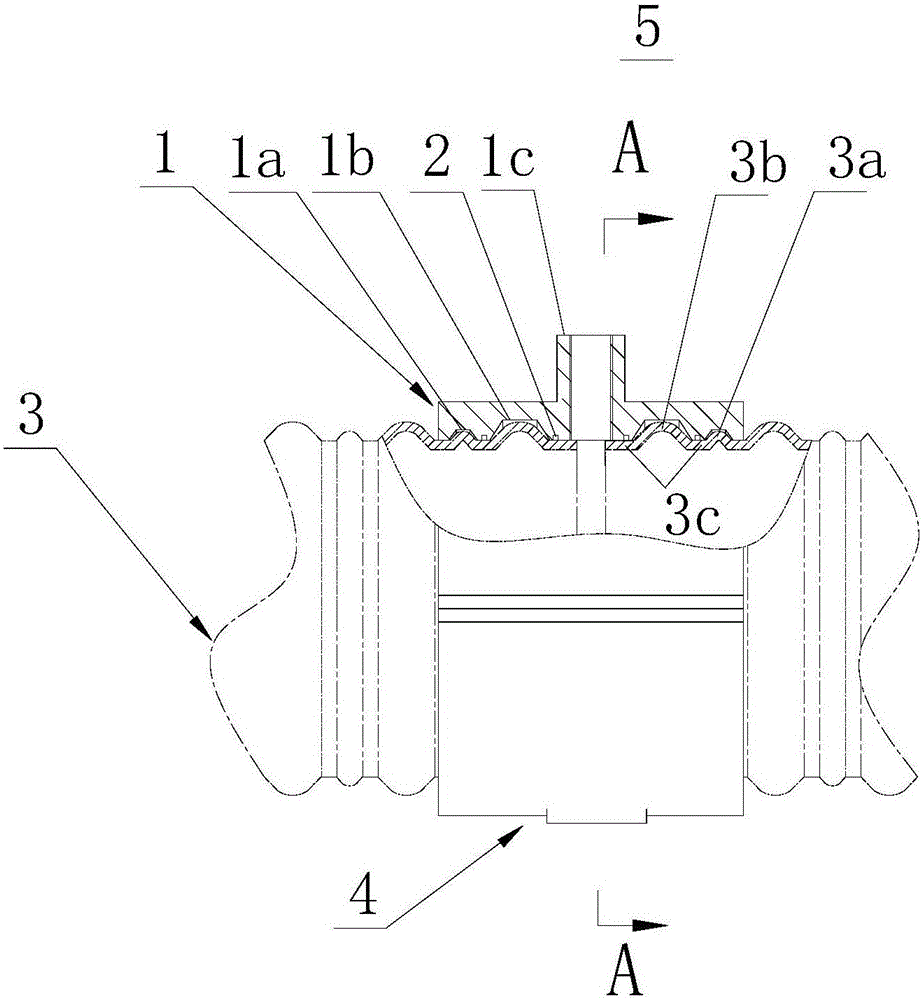

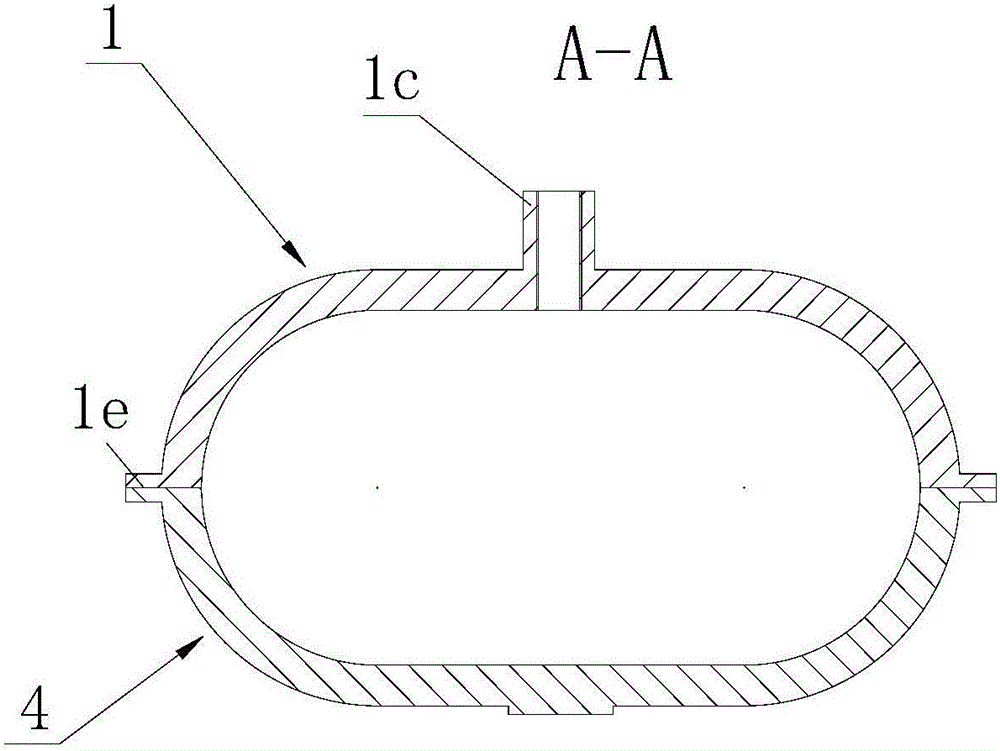

[0025] The present invention provides a sealing joint 5 for connecting a bamboo-shaped prestressed flat-mouthed plastic pipe with an exhaust pipe. The sealing joint 5 is butted and combined by the first half of the flat-mouthed pipe 1 and the second half of the flat-mouthed pipe 4 A sealing joint 5 with a flat mouth type is formed in the cross section.

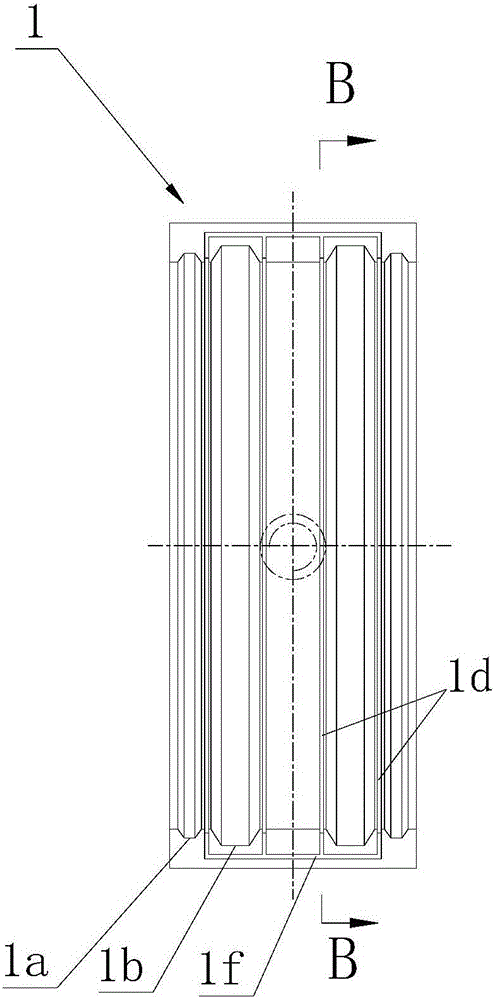

[0026] Such as figure 1 , figure 2 As shown, on the outer edge of the first half flat pipe 1, there is protrudingly provided with an exhaust pipe 1c penetrating through half of the flat pipe wall. The inner hole of the exhaust pipe 1c is a threaded hole, and the exhaust pipe 1c is arranged in the middle of the outer edge of the first half of the flat mouth pipe 1. The gap between the ends of the stress flat mouth plastic pipe 3.

[0027] On the inner ring of the first half flat tube 1 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com