Humidity detection and intervention device for industry dryer

A humidity detection and drying machine technology, which is applied in drying, drying solid materials, lighting and heating equipment, etc., can solve the problems of accuracy and sensitivity, drying time damage of dried objects, and inaccurate humidity detection. To achieve the effect of ensuring accuracy and sensitivity, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

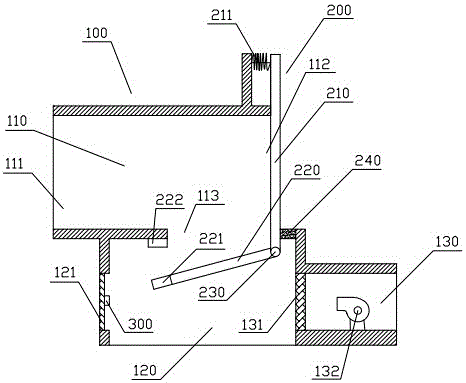

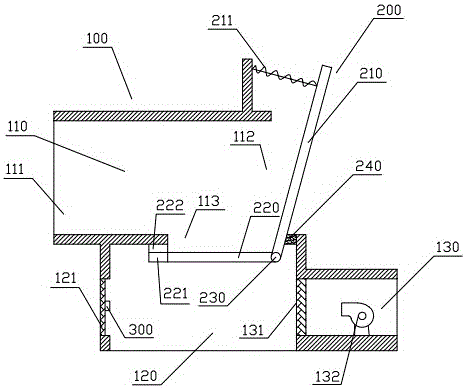

[0016] Such as figure 1 As shown, the present invention is a humidity detection and intervention device for an industrial dryer, which includes a device body 100, a valve assembly 200 and a dryer controller.

[0017] The device body 100 is provided with an air inlet chamber 110 , a measurement chamber 120 and a blast chamber 130 . The air intake chamber 110 is provided with an air intake end 111 connected to the exhaust port of the dryer, and the steam generated during the operation of the dryer enters the air intake chamber 110 from the exhaust port. In the air inlet chamber 110, there is an inner exhaust port 113 communicating with the measuring chamber 120 and an outer exhaust port 112 communicating with the outside of the dryer. Steam can enter the measuring chamber 120 through the inner exhaust port 113, or through the outer exhaust port. End 112 exits the dryer. The measurement chamber 120 is provided with a measurement exhaust port communicating with the outside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com