A tool for testing the air tightness of the oil channel of the automatic transmission case

A technology of air tightness detection and automatic transmission, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problem of inability to judge the mutual penetration of oil passage holes and oil passages, and false detection , Affect the reliability of test results and other issues, to avoid quality risks, avoid false detection, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

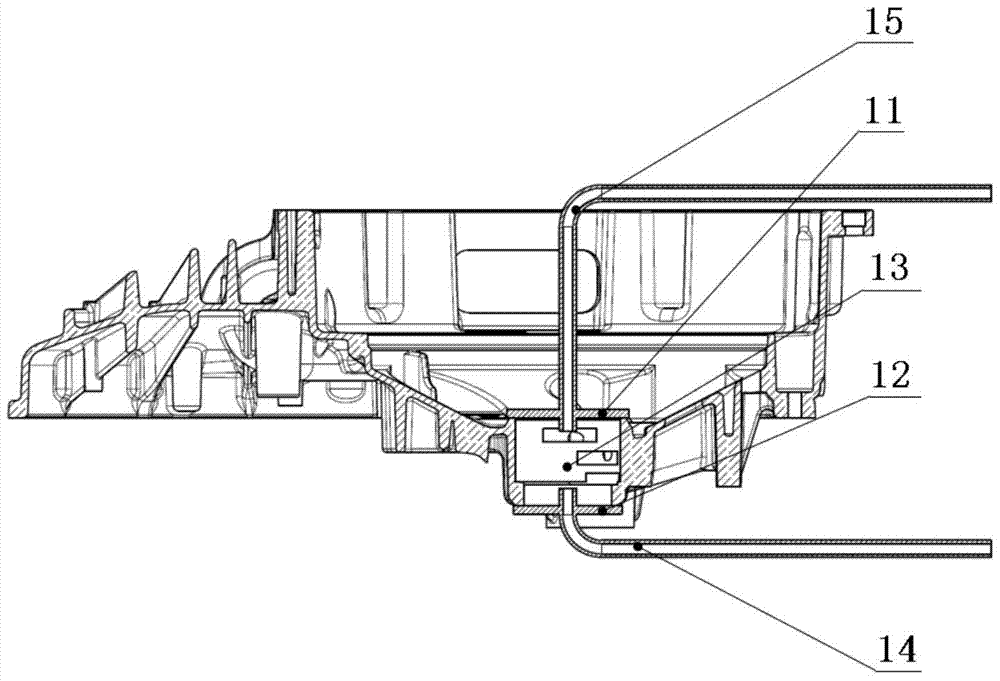

[0028] The core of the present invention is to provide an automatic transmission casing oil channel air tightness detection tool, in order to realize the separate sealing of the oil channel holes in the case where multiple oil channels communicate with the same bearing hole, so as to avoid False detection occurs when the oil passage is penetrated, which improves the reliability of the detection results and avoids quality risks.

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

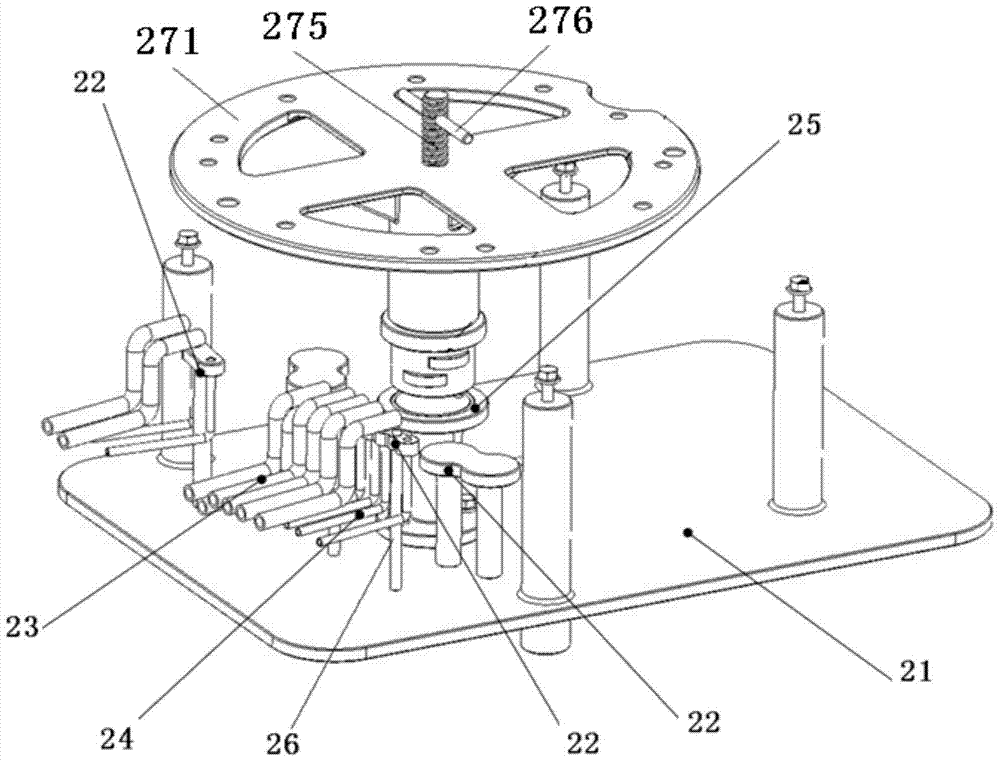

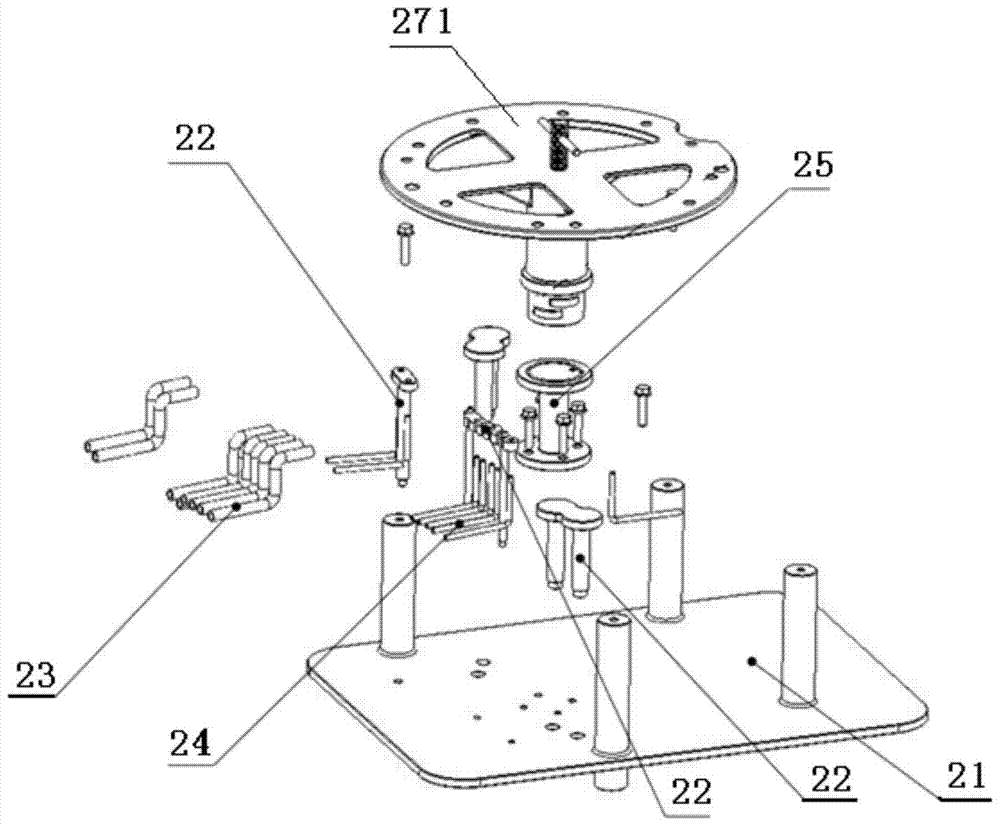

[0030] Please refer to figure 2 and image 3 , figure 2 It is a structural schematic diagram of a specific embodiment of the detection tool provided by the present invention; image 3 for figure 2 An exploded view of the inspection tooling shown.

[0031] In a specific embodiment, the automatic transmission housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com