Automatic generation method for assembly tolerance synthesis of complex assembly body

An assembly tolerance and automatic generation technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of poor tolerance information transmission, tolerance synthesis cannot be automatically generated, etc., and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

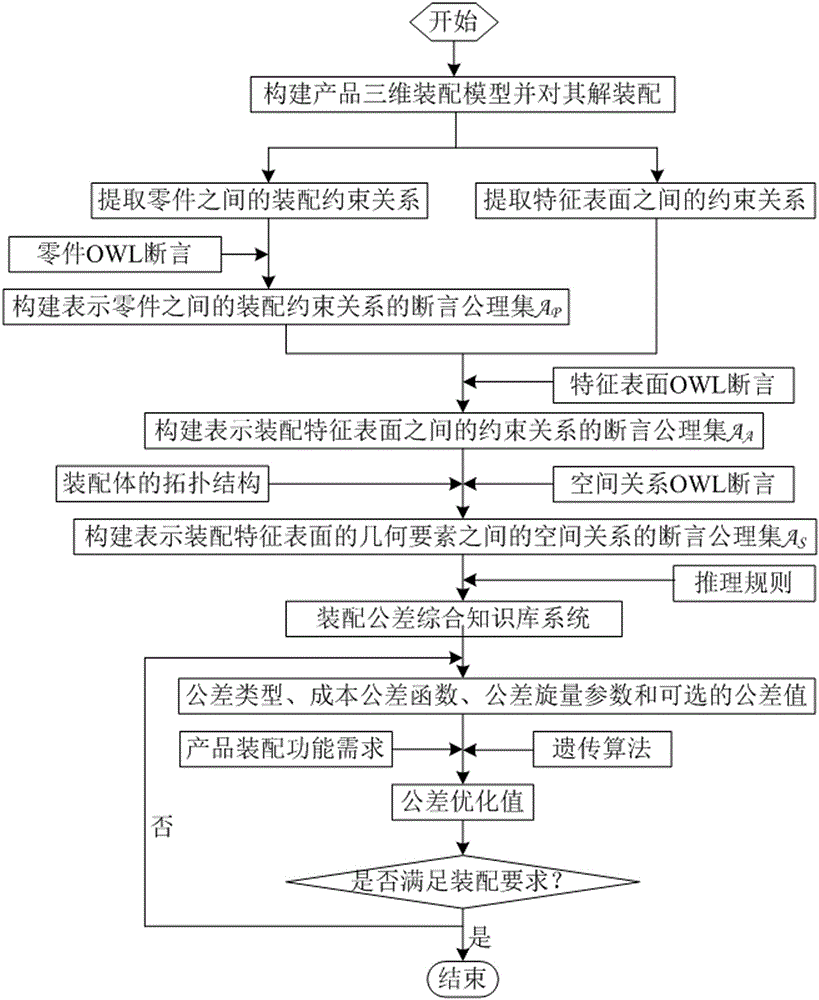

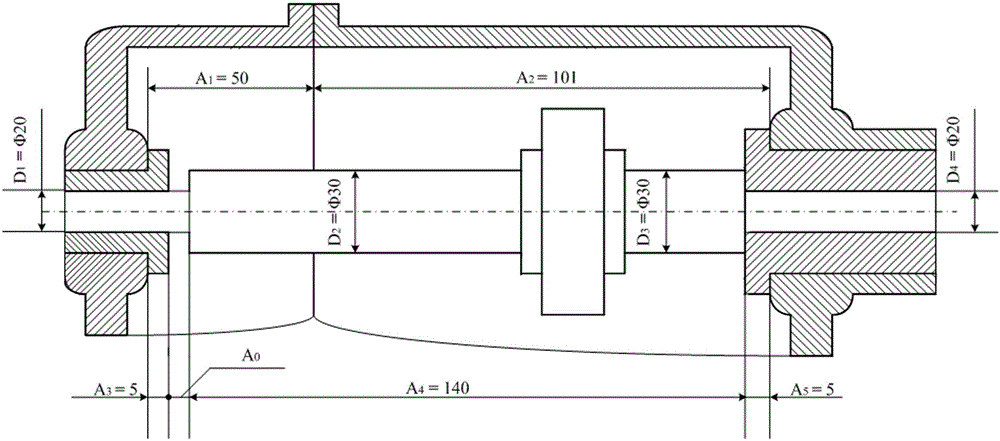

[0026] The implementation process of the method will be described below by taking a split gearbox as an example. The component is composed of a case body, a case cover, a gear shaft and a bushing, and the relevant dimension information is marked in the figure. After assembly, there is a certain gap between the shaft shoulder and the end face of the left bushing, which is A 0 , the basic dimensions and tolerances of each part are known (unit: mm), and the assembly tolerance comprehensive automatic generation process is shown in figure 1 .

[0027] Step 1: Build a 3D assembly model of the product. According to the functional requirements of the product and the ideal size of each part, a three-dimensional assembly model of the split gearbox is constructed in SolidWorks, and its partial view is shown in figure 2 .

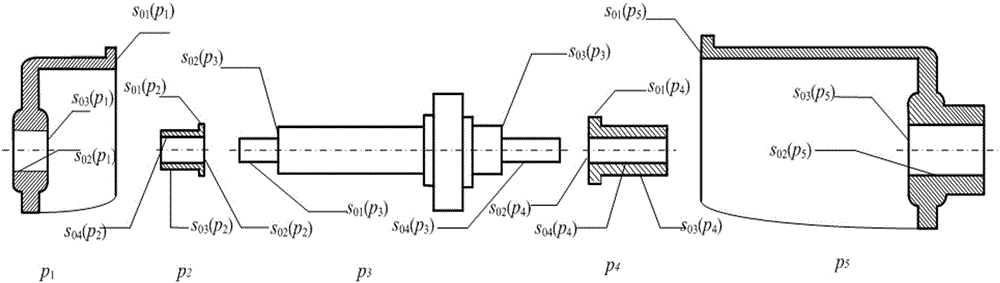

[0028] Step 2: Disassemble the 3D assembly model of the product. According to the structure of the split gearbox, its three-dimensional assembly model is disasse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com