Split clamp fitting

A technology of wire clip fittings and split wires, applied in electrical components, circuits, connections, etc., can solve problems such as unstable conduction and current performance, and achieve unstable conduction and flow performance, increase conductive contact area, and improve conduction. The effect of streaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

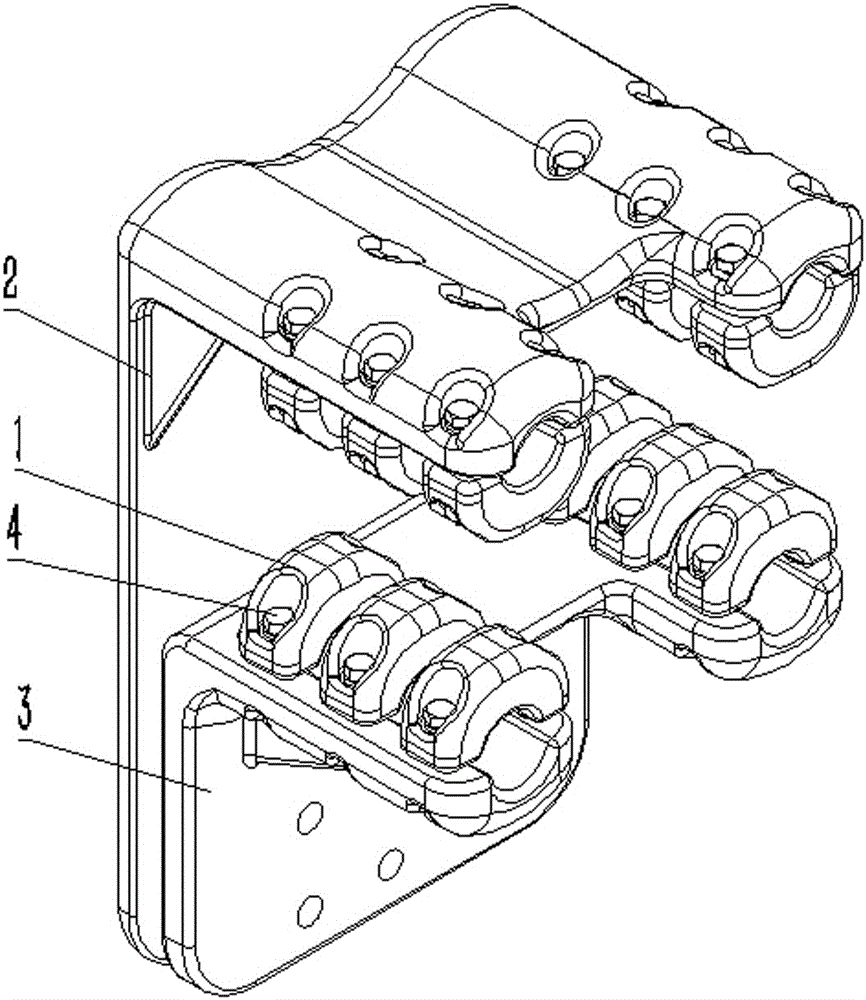

[0025] Examples of wire clamp fittings in the present invention: Figure 1 to Figure 12 As shown, the wire clamp fitting is a kind of UHV DC converter station split wire clamp fitting used for T-connection conversion between four-split conductors and terminal board 5. It is mainly composed of a clamp cover 1, an upper splint 2 and a lower splint. The cover plate is composed of the wire clamp cover plate 1, the upper splint 2 and the lower cover plate are all made of ZL101A cast aluminum silicon alloy, which reduces weight, increases strength, and has high temperature resistance and corrosion resistance.

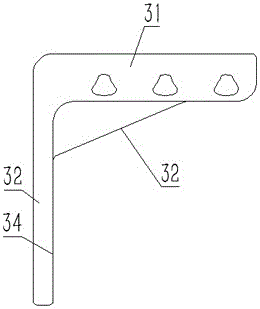

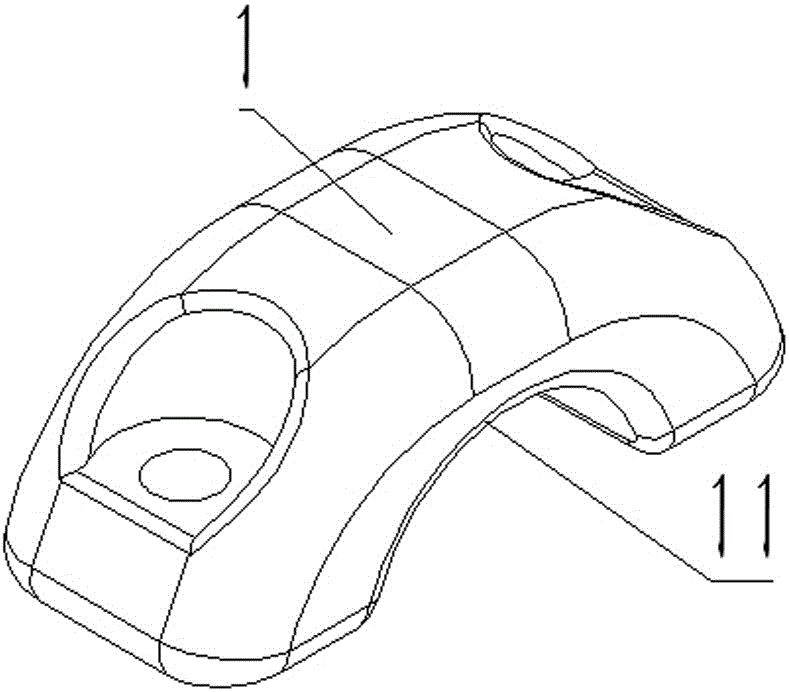

[0026] The upper clamping plate 2 is an L-shaped plate body formed by integrally connecting the upper plate 21 and the front vertical plate 22. The upper plate 21 is bent backwards at the top of the front vertical plate 22. The upper splint 2 includes upper fixing clip parts provided on the left and right sides. The upper fixing clip part is semi-cylindrical, and the convex surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com