One-line operation trolley for power transmission line

A transmission line, single-line technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of prolonging the maintenance time of transmission lines, troublesome maintenance work of transmission lines, unable to realize continuous operation, etc., and achieve the effect of continuous operation and improvement of work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the technical features of the solution, the present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

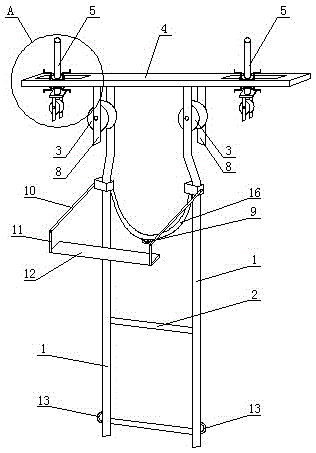

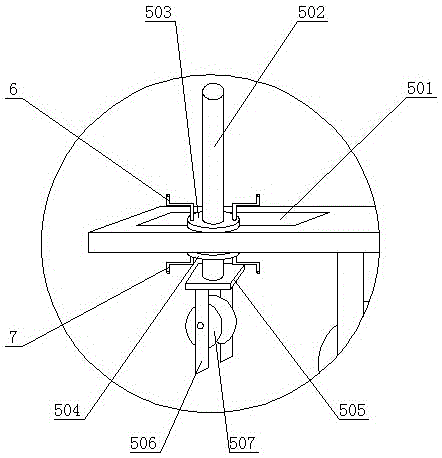

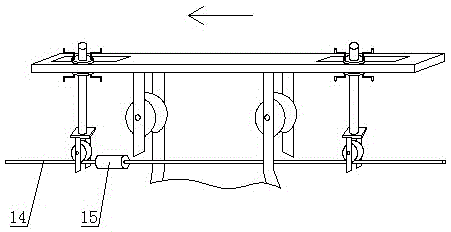

[0030] like Figure 1 to Figure 4 As shown, the present invention includes two support rods 1 , the two support rods 1 are connected by three connecting rods 2 arranged at intervals, and the uppermost connecting rod 2 between the two support rods 1 is a U-shaped rod 16 . A main pulley 3 is movably connected to the upper part of the two support rods 1, the two main pulleys 3 are arranged in a straight line, a plate body 4 is arranged above the two support rods 1, and the tops of the two support rods 1 are fixedly connected to the middle of the plate body 4. , a spanning auxiliary device 5 is respectively provided on both sides of the plate body 4 . The spanning auxiliary device 5 includes an adjustment hole 501 arranged on one side of the plate body 4 , the adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com