Method for producing film formation mask

A manufacturing method and mask technology, applied in chemical instruments and methods, vacuum evaporation plating, coating and other directions, can solve the problems of metal part fracture, wrinkling, opening pattern deformation, etc., and achieve the effect of improving the accuracy of the forming position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

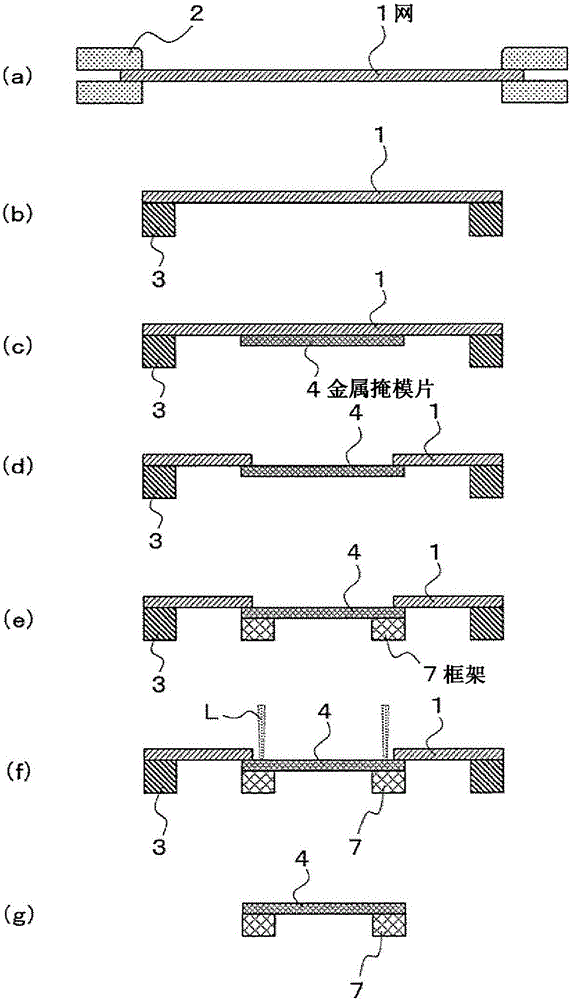

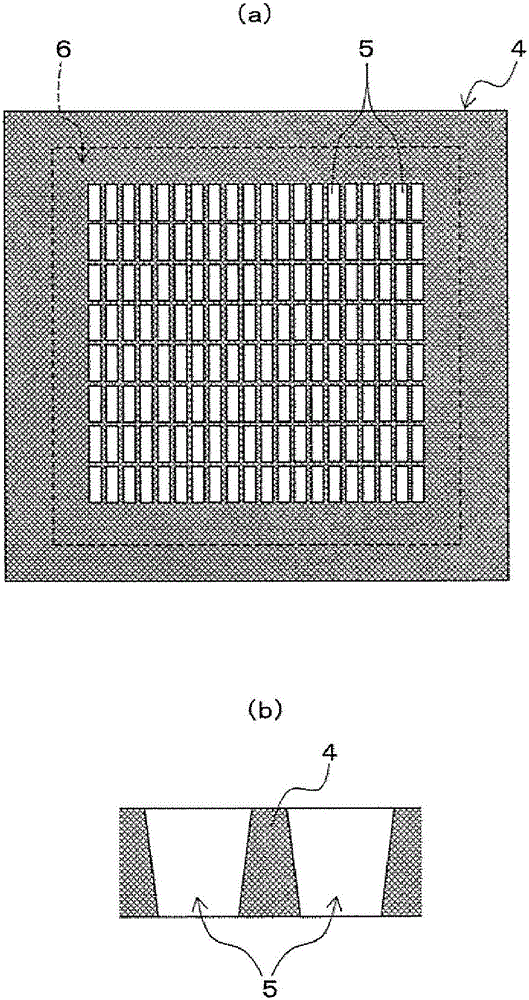

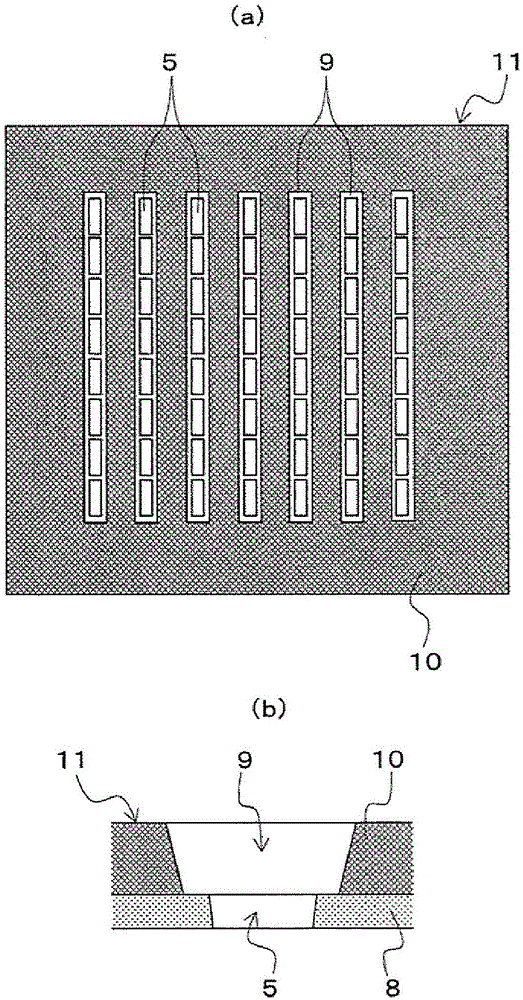

[0018] Embodiments of the present invention will be described in detail below based on the drawings. figure 1 The embodiment showing the method of manufacturing the film-forming mask of the present invention is a cross-sectional view showing the step of joining the mask sheet to the frame. The film-forming mask manufacturing method manufactures a film-forming mask having a structure in which a mask sheet formed with a plurality of opening patterns is tensioned and fixed to a frame-shaped metal frame, and the following steps are performed: In the first step, a certain Bond the peripheral portion of the mask sheet on the net of the synthetic fiber of tension; the 2nd step, the part of the net corresponding to the film-forming effective area of the size containing a plurality of opening patterns in the mask sheet is cut off; the 3rd step, in The peripheral portion of the mask sheet is joined to fix the frame from the side opposite to the mesh; and in a fourth step, the mesh is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com