Magnetic head, magnetic head apparatus and shielded enclosure

A technology of shielding cover and magnetic head, which is applied to the housing/shielding cover of the recording head, the manufacture of magnetic heads with a structure composed of multiple magnetic heads, and magnetic recording heads. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

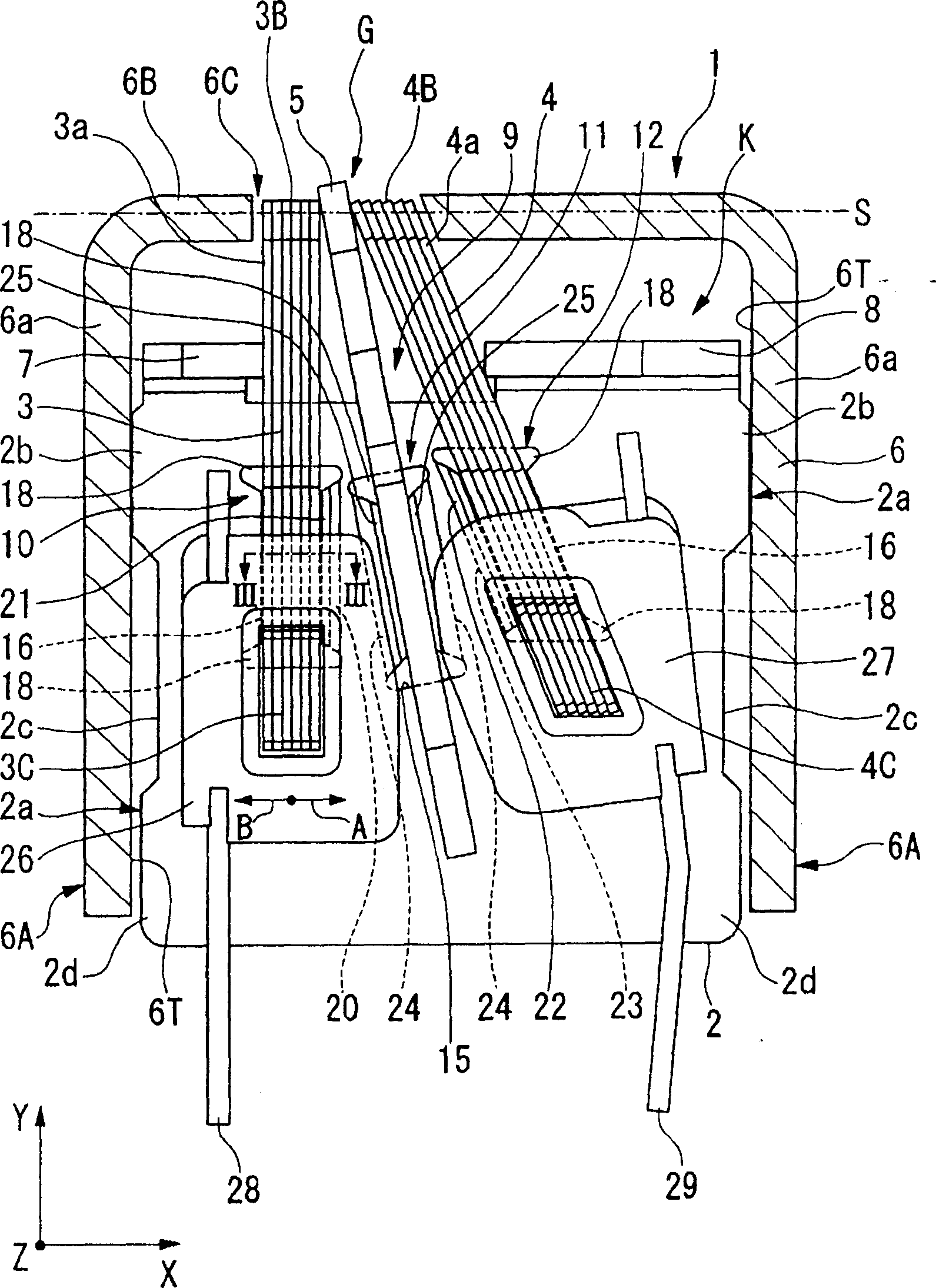

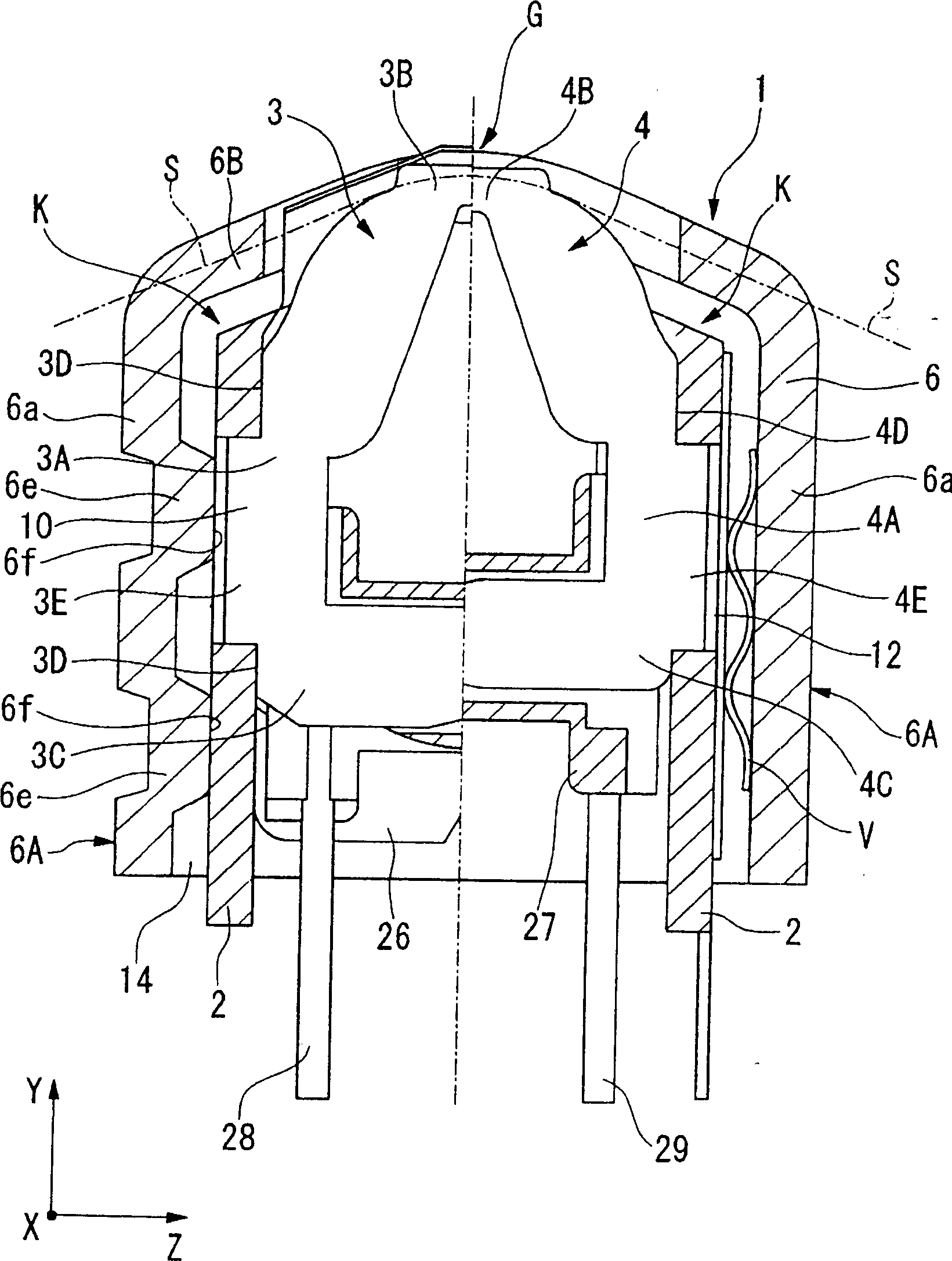

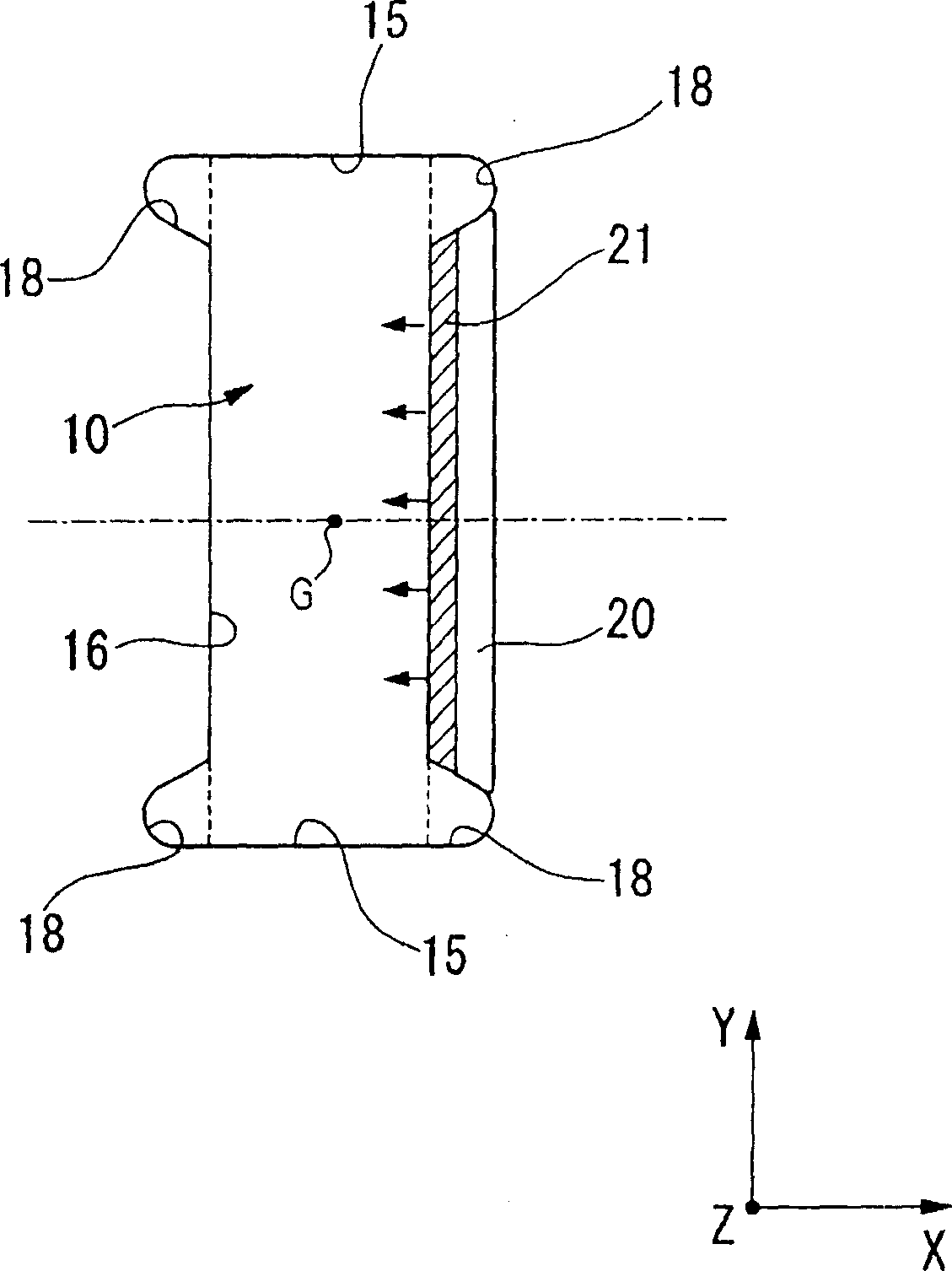

[0051] Next, a magnetic head according to a first embodiment of the present invention will be described with reference to the drawings.

[0052] like figure 1 and figure 2 As shown, on the base member 2 made of plastically processed metal plate, two magnetic core assemblies K with magnetic core halves 3, 4 and shielding plate 5 are assembled, and then both are stored in the shielding case 6, thus constituted The magnetic head 1 of the first embodiment.

[0053] In this embodiment, four peripheral walls 6a form a square cylindrical case 6A, and a front wall 6B is formed to close one side opening of the peripheral wall 6a, and the shield case is constituted by the case 6A and the front wall 6B. 6. The shield cover 6 is integrally formed by deep drawing of a metal material, and a window portion 6C is formed at a partial position of the front wall 6B. In addition, the inside of the shield case 6 is filled with a bonding resin (not shown), and the above-mentioned set of magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com