clutch device

A clutch device and friction pair technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve problems such as loss of adhesion and traction and increase manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

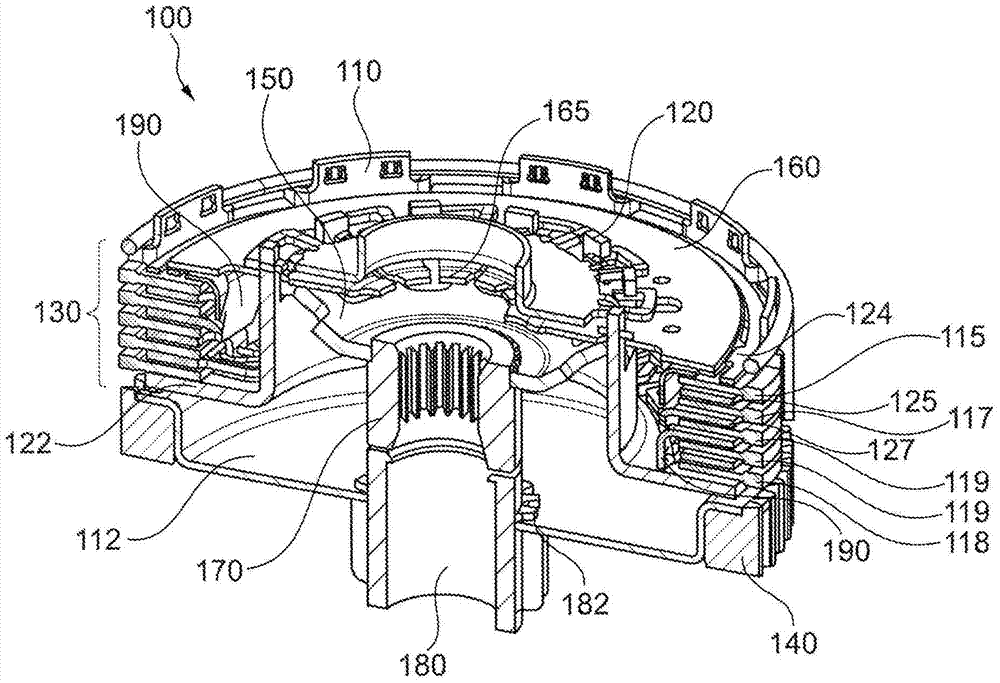

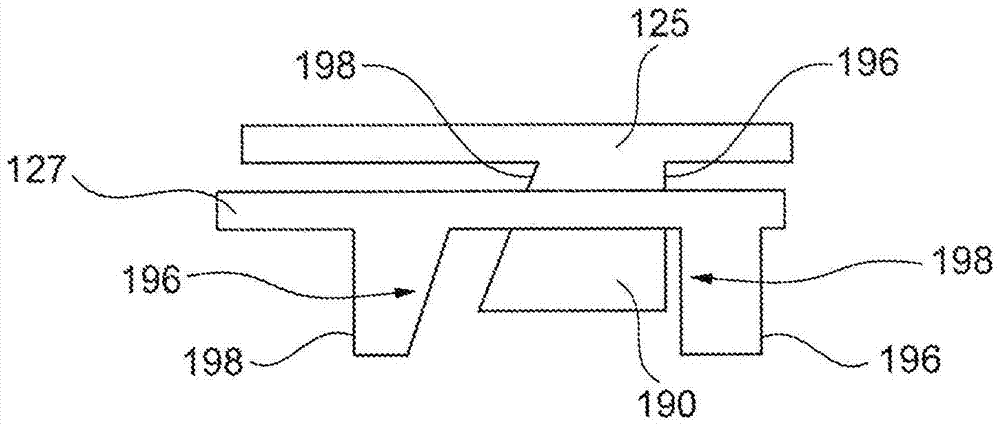

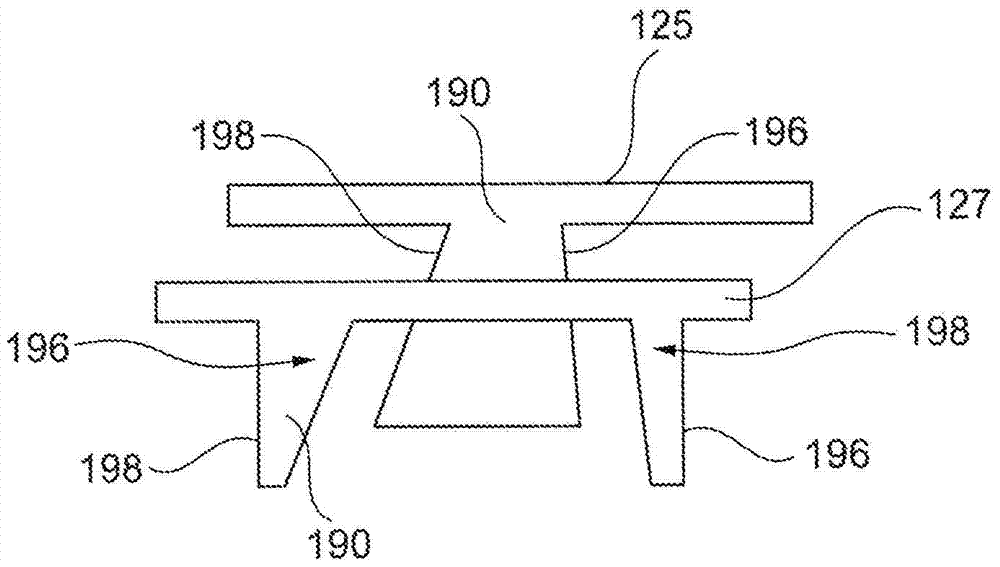

[0025] exist figure 1 The clutch device 100 according to the invention shown in is a vehicle clutch, in particular in the form of a motorcycle clutch. The clutch device 100 comprises an input side and an output side, wherein the input side and the output side are mounted rotatably about an axis of rotation. The clutch device 100 has an outer bracket 110, an inner bracket 120, and an outer bracket 110, except for parts that are also provided in a conventional clutch device (these parts are not explained in detail here because they are not necessary for explaining the principles of the present invention). A plurality of friction pairs 115, 117, 118, 119 connected, a plurality of friction pairs 124, 125, 127, 128, 129 connected with the inner bracket 120, a primary gear 140, a transmission element 150, a disc spring 160, a driven hub 170 , bushing 180 and a plurality of connecting elements 190 .

[0026] The input side has a primary gear 140 with toothing. The torque from an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com