Folding type harvester

A technology for harvesters and cutters, applied to harvesters, agricultural machinery and implements, applications, etc., can solve problems such as cumbersome and time-consuming operations, affecting work efficiency, and affecting the movement of harvesters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

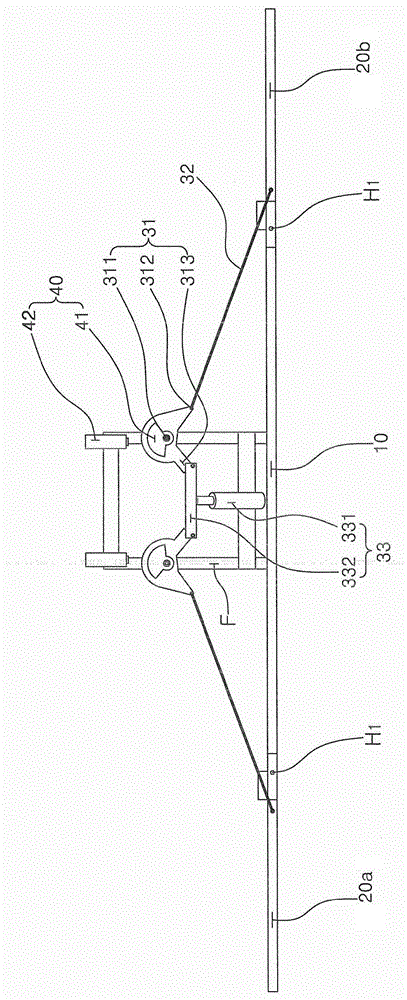

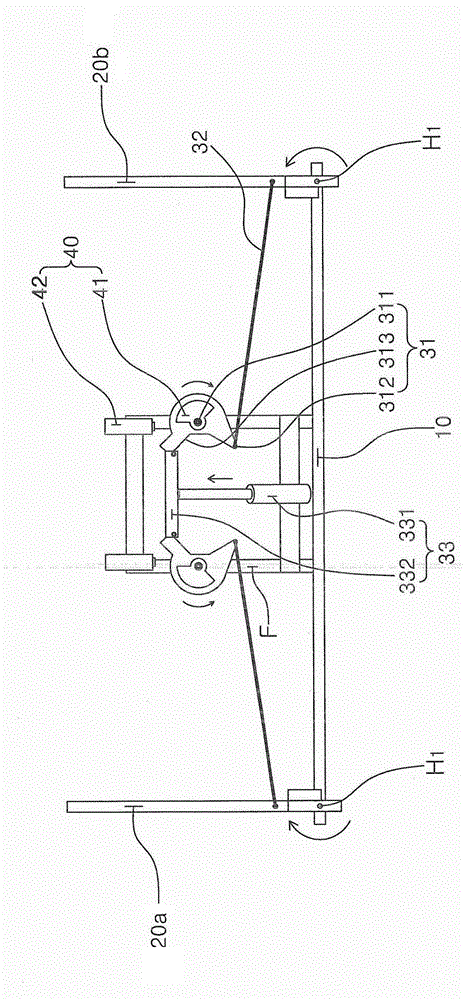

[0022] The reference signs in the accompanying drawings of the specification include: right segment rod 20b, left segment rod 20a, middle segment rod 10a, fixed sleeve 331, horizontal segment 332, telescopic sleeve rod 33, elastic plastic plate H1, vertical rod F, abutting part 313, connecting portion 312, traction rope 32, pin shaft 311, protrusion 41, stop mechanism 40, limit sleeve 42, runner 31, folding mechanism 30, harvester body T.

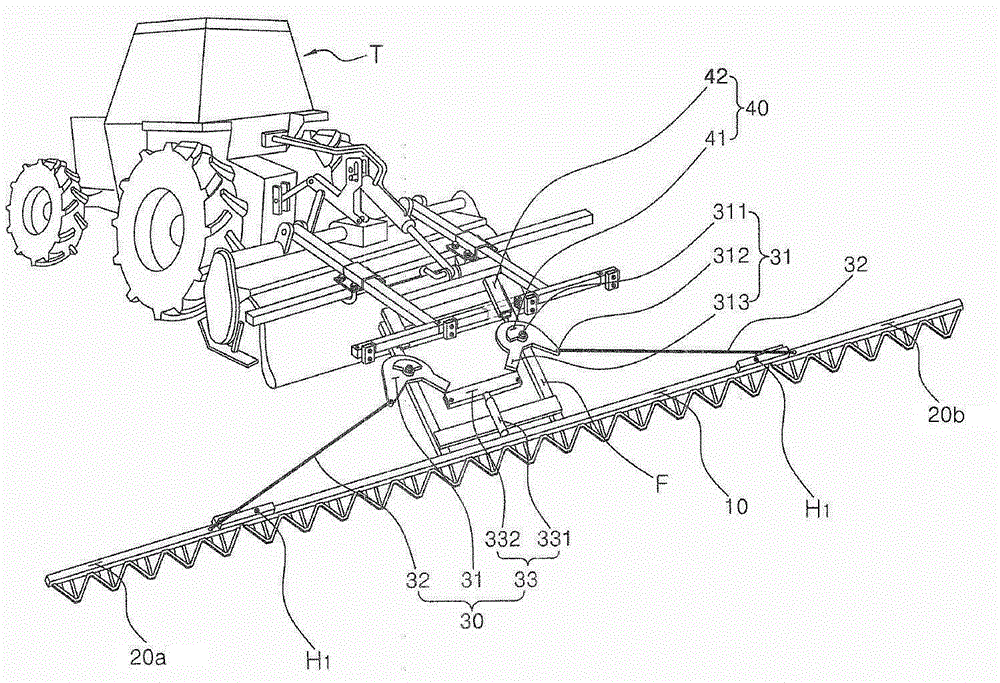

[0023] Such as figure 1 As shown, the folding harvester in this embodiment includes a harvester body T and a cutter arranged in front of the harvester body T, and the cutter includes a straight rod and a row of target teeth fixed on the straight rod.

[0024] The straight bar and the harvester body T are provided with a fixed mount. The fixed frame is a frame structure composed of two vertical bars F and two cross bars. The two vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com