Vehicle-mounted tool case

A toolbox and tool technology, applied in the manufacture of tools, workshop equipment, etc., can solve the problems of hidden safety hazards for construction personnel, rare toolboxes, time-consuming and labor-intensive handling of tools and materials, etc., to ensure safety and improve maintenance progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

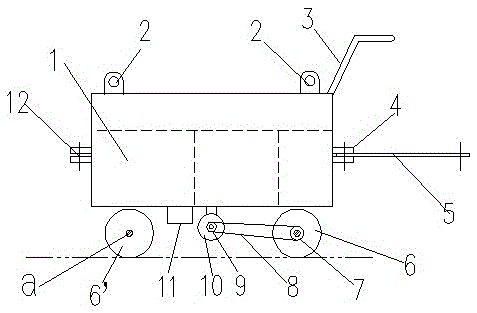

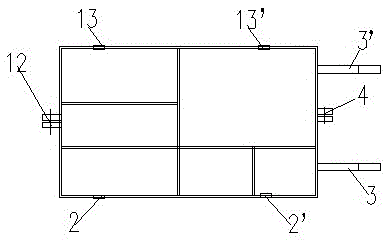

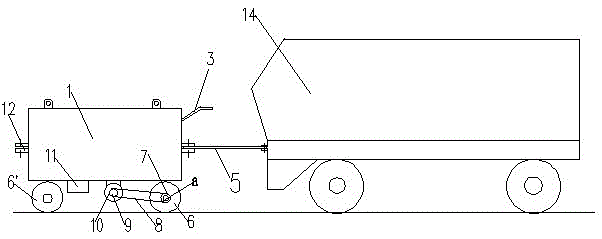

[0011] given in the present invention figure 1 , figure 2 , image 3 In the embodiment of the present invention, a rectangular tool box 1 is welded with a metal plate, and the rectangular tool box 1 is provided with a tool compartment, which is used to store different tools and materials. The handle 3 is provided with a first lug 2 and a second lug 2' at the top of one side of the rectangular toolbox, and a third lug 13 and a fourth lug 13' are respectively provided at the top of one side of the box. In the middle of the outer walls of the left and right ends of the rectangular toolbox, there are respectively a first earring 4 and a second earring 12; The hooks on the top are assembled together. The bottom plate of the rectangular toolbox is fixed with a roller shaft a at the front and back; the bearings installed in the center of the first roller 6 and the second roller 6' are respectively set on the two ends of the wheel axle a, and one side is provided with an arc-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com